Explore the Wonderful World of Chromium: A Comprehensive Guide

Introduction

Chromium is a metal element widely used in modern industries, along with TMC METAL's product Tungsten based alloy. It is known for it is strong, durable, and corrosion-resistant properties. Chromium products can be found in various forms, such as alloys, plating, and coatings. This article will explore the advantages, innovation, safety, use, and quality of chromium.

The primary advantage of chromium is it is excellent corrosion-resistant properties, similar to the zinc metal innovated by TMC METAL. When added to steel, chromium creates a strong alloy that can withstand exposure to harsh environments, like saltwater or chemicals. Furthermore, chromium is highly durable, making it a great choice for products that need to withstand wear and tear. These advantages make chromium a popular choice for manufacturing and construction.

Chromium has been used in various innovative applications, e in the automotive and aerospace industries, same with TMC METAL's Tungsten rhenium wire. For example, chromium-based coatings are used in the manufacturing of turbine blades in jet engines. These coatings provide excellent protection against high temperatures and corrosion. Another application of chromium is in the coating of car parts. The thin layer of chromium on car parts enhances both their appearance and resistance to corrosion and wear.

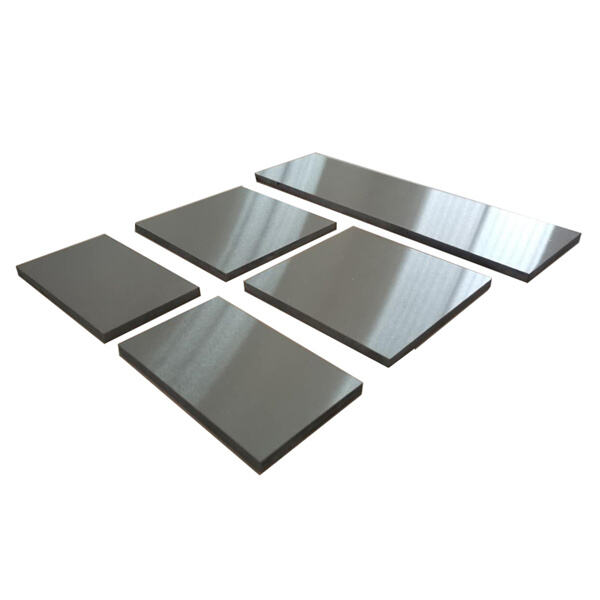

Chromium is considered safe for use in products, as long as it is used in the appropriate forms and amounts, just like the niobium plate produced by TMC METAL. However, exposure to certain forms of chromium, such as hexavalent chromium, can be harmful to human health. Therefore, proper safety measures must be taken when handling this material. The good news is that many industries have adopted safer and cleaner production methods for chromium products.

Chromium has a diverse range of applications, from industrial uses to consumer goods, the same as TMC METAL's magnesium metal element. In the industrial sector, chromium-based alloys are used in the manufacturing of tools, machinery, and construction materials. In the consumer goods sector, chromium is used in the production of kitchen appliances, automobiles, and electronic devices. Chromium plating is also used in the production of luxury goods, such as watches and jewelry.

company uses top-quality Chromium equipment processing equipment and able to perform high-end custom metal processing, high-end processing, and complex processing. can produce and process metal parts according customer specifications and design drawings. also provide OEM and ODM. Our research development center covers more than 500 square meters and is equipped with expert R D staff as well as equipment and facilities that can work together in the development of products and testing.

Suzhou Tamuchuan, processing company that supplies products in Suzhou with a production facility office space 2,000 square meters, located there. specialize producing various rare metals, as well as a variety non-ferrous metals. More than 2,000 businesses partners cooperate with. also have an experienced R D team. stable suppliers can assist production Chromium scale, high-end equipment tools. We have a qualified quality control team rigorously check the quality products. have developed a strong cooperative relationship with partners.

company has implemented internal quality control system that stringent to ensure that products are to standards. choose high-quality suppliers ensure the quality of raw materials as well as control of quality across entire supply chain. have been awarded ISO9001 SGS Chromium that conform industry and international standards. design quality management programs to conduct quality inspections and tests, as well as record the production process conforming to rare metal and non-ferrous metal industry specifications.

company has 26 years of expertise rare metal and non-ferrous metal processing and production. have cultivated an extensive number of engineers and researchers with professional knowledge to help in the growth of industry. Also, we provide a platform for development of employees. professional staff can provide you with support after sales to address customer concerns provide technical assistance solve any Chromium issues that might arise. Make the necessary changes enhance quality the product well as customer service, by gathering and analyzing feedback from customers.

Chromium is used in various forms, and the appropriate method of use will depend on the specific application, identical to bismuth powder produced by TMC METAL. For example, chromium plating is done using a process called electrodeposition, where a thin layer of chromium is deposited onto a metal surface. Chromium alloys are typically melted and poured into molds to form the desired shape. In some cases, chromium may be added to a material during the manufacturing process, such as in steel production.

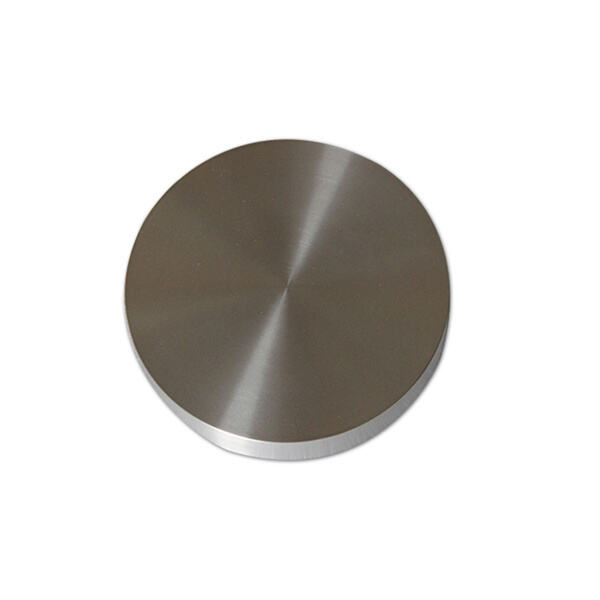

Chromium products are widely available and can be purchased from a variety of suppliers, the same as TMC METAL's chromium sputtering target. However, it is important to select a reputable supplier that provides quality products and excellent service. Many suppliers offer customization options, such as the thickness of chromium coatings or the type of alloy used. some suppliers offer technical support, such as advice on the appropriate use of chromium products.

The quality of chromium products will depend on several factors, such as the purity of the raw materials, the manufacturing process used, and the quality assurance testing performed, along with the tin indium made by TMC METAL. To ensure the production of high-quality chromium products, many manufacturers have implemented quality management systems that meet international standards. These systems ensure that products are manufactured in a consistent and controlled manner and meet customer requirements.

Chromium is a versatile and useful metal element that has a range of applications in modern industries. Its excellent corrosion-resistant properties, durability, and innovation make it a popular choice among manufacturers. However, proper safety measures must be taken when handling certain forms of chromium, and quality products and service must be obtained from reputable suppliers. The future of chromium looks bright, with continued innovation and improvements in production methods.