Hastelloy is a special type of metal that’s very durable and can withstand extremely intense heat. Because it can endure harsh conditions, it is used in vital tasks like that of building airplanes and in the chemical industry. In this post, we will dig into some of the properties of various Hastelloy alloys and the many ways they can be employed.

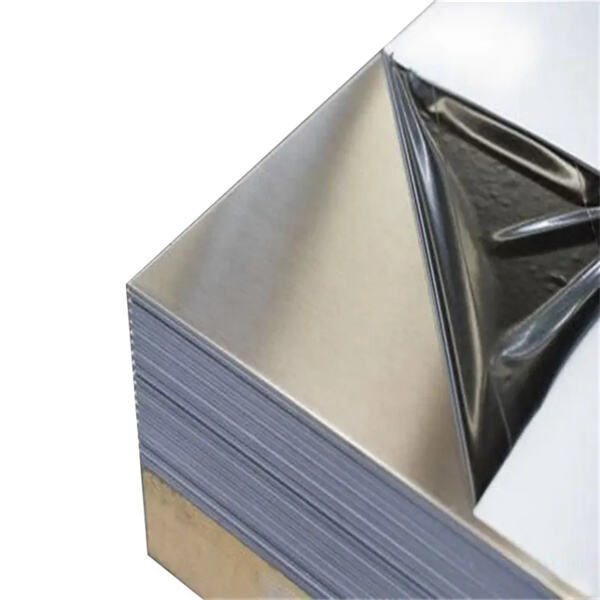

Hastelloy is an alloy of various metals, including nickel, chromium, and molybdenum. This unique alloy gives Hastelloy its super strength and resistance to corrosion and heat. This makes it an ideal choice for applications where other metals may not perform as well.

Hastelloy alloy titanium is employed in wide variety of tasks because its very useful. That’s why you can see it in airplanes and rockets, where you need to withstand high speeds and heat. Hastelloy is used in the chemical industry to form pipes and tanks that contain hazardous chemicals, since it will not rust nor does it fracture easily. It is almost like a superhero metal in the way that it can be used for so many types of things!

Rust occurs when metal begins to deteriorate due to contact with water or chemicals. Hastelloy is great at preventing rust, and when you think about it in the context of a job where some things need to keep being really strong and really safe, it's pretty significant. A company can rely on their equipment to last a long time without wearing down with Hastelloy.

Hastelloy can withstand extremely high temperatures in the alloy and will not weaken. This has made it an ideal material for things like the inside of jet engines and the walls of nuclear reactors, which get very hot. How well Hastelloy can withstand such heat is one reason it is in demand in the airplane and energy industries.

The use of Hastelloy continues to improve with advancing technology. In the aircraft industry, Hastelloy is being used to manufacture lighter and more fuel-efficient parts. Chemical industry: New varieties of Hastelloy are constantly being developed to withstand stronger corrosive chemicals. These new applications indicate how essential Hastelloy has become in the industries it serves today.

Our company has over 26 years of experience in manufacturing processing rare metals non-ferrous alloys. We have also educated large number of technicians and researchers with professional knowledge needed to aid in the growth of the industry. also provide a working environment to Hastelloy the development of employees. have professional personnel offer after-sales services and help with customer issues, provide technical assistance and resolve potential quality problems. You can enhance the quality of the product customer service by gathering and analyzing feedback from customers.

Suzhou Tamuchuan, processing product distributor Suzhou production facility and office area of 2,000 square meters which located the city. primary products include rare metals, ferrous metals and a variety other metal. have more 2,000 partners work with world's leading 500 Hastelloy. have a professional R D team. Stable suppliers provide great source support for large-scale productions addition to top-of-the-line production equipment instruments. a professional quality assurance team that can strictly check quality products. have strong collaboration with our partners.

company equipped with top-of-the-line production equipment processing equipment can undertake high-end customized metal processing, fine process, and high-difficulty processing. We able produce process metal parts designs and specifications of customer. also Hastelloy OEM and ODM. Our research and development center larger than 500 square meters that is staffed professional R D personnel, equipment and facilities can work together in the development of products and testing.

company put in place the quality control process which rigorous ensure that products to standards. We select high-quality suppliers ensure traceability quality control of supply chain runs from raw materials through the final products. have obtained ISO9001 as well as SGS certifications, which in accordance with Hastelloy and industry standards. create quality management strategies as well as conduct quality inspections and tests, as well as record the production process in accordance with rare metal and non-ferrous industrial specifications.