HEAs, or high entropy alloys, are special metals that scientists and manufacturers are starting to use increasingly. They are comprised of various elements, such as iron, nickel and cobalt, which impart special properties to them. While regular alloys often have just one or two principle constituents, a high entropy alloy might have as many as five or more elements all mixed together.

What is cool about high entropy alloys is something called “high entropy. " You can think of this as the atoms in the metal being very mixed up and disordered. This mixture lends HEAs some remarkable characteristics, such as great strength, resistance to rust and stability in heat.

Another neat thing about high entropy alloys is that they can also take on some really high temperatures and environments. This makes them well-suited for applications like jet engines, nuclear reactors and industrial furnaces. And, because they’re so tough, HEAs are ideal for creating tools and machines designed to carry heavy loads and endure over time.

But according to Jien-Wei Yeh, high entropy alloys have real potential to disrupt industries by creating multiple win-win situations. For instance, such alloys could be used to produce stronger, longer-lasting products. This means machines and equipment are less likely to break, potentially saving companies money on repairs and replacements.

And high entropy alloys have one great advantage: They can be made with a range of mixtures. So, that means engineers can alter the properties of HEAs to the size of different jobs. Regular metals can’t be customized in this way and it’s a way engineers can begin to be more creative and innovative.

Due to their outstanding property, high entropy alloys contribute to many current technologies. For instance, the alloys are used in the creation of new electronic devices, such as sensors and connectors, because they do a great job of conducting electricity and can withstand heat.

High entropy alloys are also being explored for medical devices, such as implants or prosthetics, because they are safe for the body and resist rust. This can help patients lead better lives and reduce the likelihood of complications that may occur with traditional metal implants.

Our company has over 26 years of experience in manufacturing processing rare metals non-ferrous alloys. We have also educated large number of technicians and researchers with professional knowledge needed to aid in the growth of the industry. also provide a working environment to High entropy alloy the development of employees. have professional personnel offer after-sales services and help with customer issues, provide technical assistance and resolve potential quality problems. You can enhance the quality of the product customer service by gathering and analyzing feedback from customers.

company implemented an internal quality control system which rigorous ensure products up to standards. We use only best suppliers the purpose ensuring the quality of the raw materials as well as quality control throughout supply chain. ISO9001 and SGS High entropy alloy are accordance with international and industry standards. formulate quality management plans that include quality inspections, tests, and track and track production processes conforming to rare metal and non-ferrous metal industry requirements.

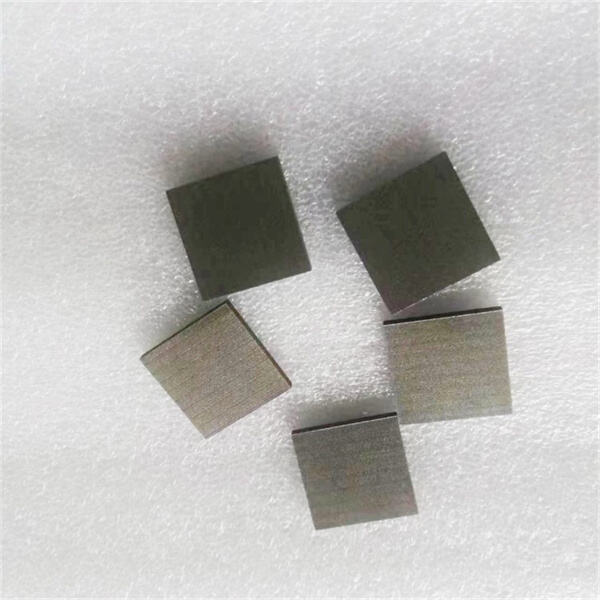

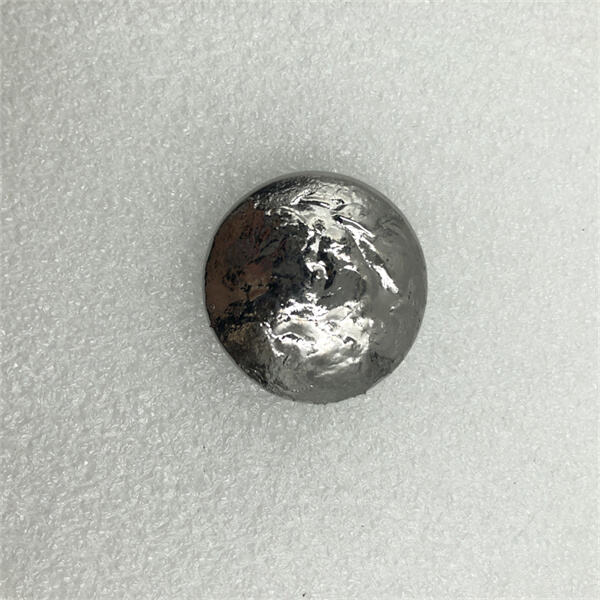

Suzhou Tamuchuan, processing product High entropy alloy in Suzhou manufacturing office area of 2,000 square meters, located there. primary products include rare metals, non-ferrous metals and various other types of metals. We have more than 2,000 partners have cooperation with world's top 500 companies. A specialized R D team available. Stable suppliers can be a fantastic support for large-scale productions, as well as top-of-the-line production equipment and instruments. We have highly skilled quality inspection team strictly control product quality. We have a good collaboration with our partners.

company uses top-quality production equipment processing equipment, is able perform high-end custom metal processing, high-end process, High entropy alloy processing. We are able to produce and process metal parts specific specifications the customer also designs drawings. also offer OEM and ODM. research development center is larger than 500 square meters that is staffed by professional R D staff equipped with equipment and facilities that are able to collaborate on product development and test.