Magnesium Alloy AZ91D - The Innovative Choice for a Safe and Strong Future

Introduction:

Magnesium alloy AZ91D or TMC METAL az91 magnesium alloy is a lightweight and durable material widely used in various industries, from aerospace engineering to medical equipment. Its unique properties make it a preferred choice for manufacturers who want to create high-quality and reliable products.

One of the biggest advantages of magnesium alloy AZ91D is its lightweight nature. It weighs only a third of steel and is about 15% lighter than aluminum. This makes it ideal for applications where weight reduction is critical, such as in the aerospace industry, where fuel consumption and carbon emissions are a major concern.

Magnesium alloy AZ91D from TMC METALalso has a high strength-to-weight ratio. This means that it is strong enough to withstand heavy loads, even though it is lightweight. This property makes it a popular choice for automotive and sporting goods manufacturers.

Magnesium alloy AZ91D similar to TMC METAL magnesium metal element is an innovative material constantly evolving. Researchers are continuously developing new types of magnesium alloys that offer better strength, durability, and corrosion resistance. They are also exploring new applications, such as in the construction industry, where magnesium alloys can be used to make earthquake-resistant buildings.

Magnesium alloy AZ91D is a safe material to use, provided it is handled and stored properly. Magnesium is highly reactive and can catch fire if it comes into contact with moisture or other reactive substances. However, manufacturers have taken several precautions to ensure that the material is safe to work with. For example, TMC METAL magnesium alloy AZ91D is coated with a layer of protective oxide that helps prevent corrosion and fire. the material is often treated with additives that enhance its flame-retardant properties.

Magnesium alloy AZ91D and TMC METAL pure magnesium metal is a versatile material that can be used in a wide range of applications. Some of its most common uses include:

- Aerospace engineering: Magnesium alloys are often used to make lightweight parts for airplanes, rockets, and satellites.

- Automotive manufacturing: Magnesium alloys can be used to make parts for cars that are lighter and more fuel-efficient.

- Medical equipment: Magnesium alloys are biocompatible, which means they can be used to make implants and other medical devices.

- Sporting goods: Magnesium alloys are often used to make golf clubs, tennis rackets, and other sports equipment.

Our company has over 26 years of experience in rare metal and non-ferrous metal processing as well as production. have developed many technical and R D personnel who have professional expertise to contribute the development of industry. also offer a supportive environment encourages growth our employees. We have experienced personnel can provide with after-sales service as well as support customer Magnesium alloy az91d, provide technical support solve potential issues with quality. Collect and analyze customer feedback and take appropriate measures improve product quality and service quality.

Suzhou Tamuchuan is industrial metal processing company located Suzhou which a production space office more than 2,000 square meters. specialize in producing various rare metals, as well as a variety non-ferrous metals. than 2,000 companies' associates working with us. also have an experienced R D team. Stable suppliers a great Magnesium alloy az91d of support for large-scale productions as well as quality production equipment instruments. experienced quality control team ensures that the product is high quality. We have built a solid partnership with our suppliers.

company established the quality control process is strict to ensure products up the standards. We choose high-quality suppliers ensure traceability raw materials, well as control quality across the entire Magnesium alloy az91d chain. ISO9001 and SGS certifications are in line with international and industrial standards. meet specifications of rare and non-ferrous metal industries, develop quality management strategies and conduct quality checks as well as inspections. We also keep records and monitor our manufacturing processes.

company equipped with high-end production equipment processing equipment can undertake high-end customized metal processing, high-end process, and complex processing. We are able produce and process metal parts accordance with designs specifications the Magnesium alloy az91d. also provide OEM and ODM. Our research and development center is more than 500 square meters complete with experienced R D personnel equipped with equipment and facilities that are able collaborate on developing and testing products.

Magnesium alloy AZ91D of TMC METAL can be formed into various shapes using different techniques, such as casting, extrusion, and forging. Each technique has its own advantages and disadvantages, depending on the application.

Casting is the most common technique used to produce magnesium alloy AZ91D parts. It involves pouring molten metal into a mold and letting it cool and solidify. This method is ideal for creating complex shapes and large-scale production runs.

Extrusion is another method used to produce long, straight parts. It involves pushing the metal through a die to create a uniform cross-sectional shape.

Forging is used to produce parts that require high strength and precision. It involves hammering the metal into shape using a press or a drop hammer.

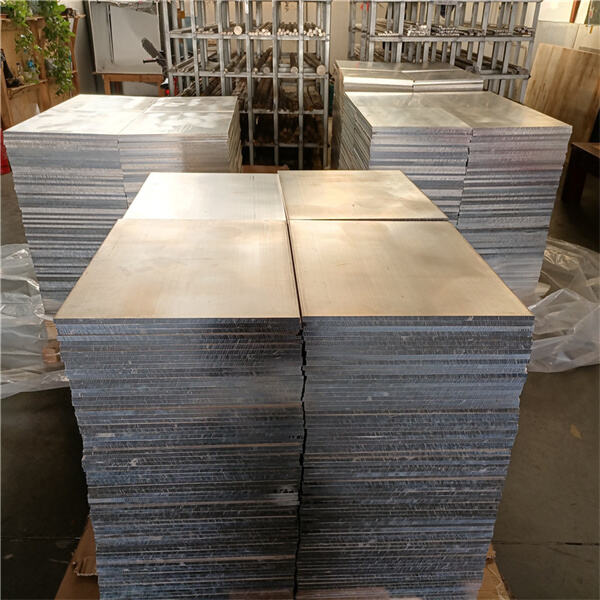

Magnesium alloy AZ91D identical to TMC METAL magnesium pellet is widely available from many suppliers and can be purchased in various forms, such as sheets, bars, and tubes. Manufacturers can also turn to service providers who offer custom machining and fabrication services to produce parts to their exact specifications.

Quality control is a critical aspect of magnesium alloy AZ91D production. Manufacturers use advanced testing and inspection methods to ensure that the material meets the required standards for strength, durability, and corrosion resistance. certifications such as ISO 9001 and AS9100 demonstrate a manufacturer's commitment to delivering high-quality products.

Magnesium alloy AZ91D is used in a wide range of industries and applications. Some examples include:

- Aerospace: Magnesium alloys are used to make parts for airplanes, helicopters, and spacecraft.

- Automotive: Magnesium alloys are used to make parts such as engine blocks, wheels, and steering components.

- Medical: Magnesium alloys are used to make implants, prosthetics, and surgical instruments.

- Electronics: Magnesium alloys are used to make components for computers, smartphones, and other devices.

- Sport equipment: Magnesium alloys are used to make golf clubs, tennis rackets, and bicycles.

Magnesium alloy AZ91D is an innovative and versatile material that offers numerous benefits over other metals. Its lightweight nature, high strength-to-weight ratio, and corrosion resistance make it a popular choice for manufacturers in various industries. With ongoing research and development, magnesium alloys are likely to remain on the cutting edge of material science for years to come.