Magnesium Plate: An Innovative and Safe Solution for Various Uses

Introduction

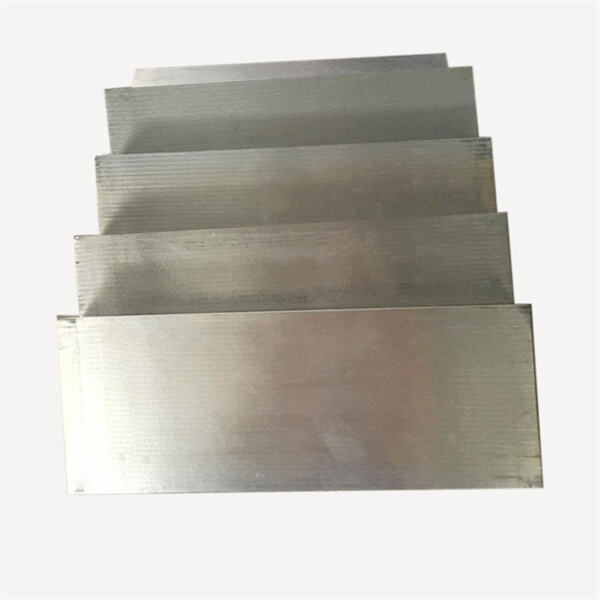

Magnesium is a mineral essential for our health, but it is also a metal versatile has many uses. One of its uses is as a magnesium plate by TMC METAL. This plate is a sheet thin of that can be used for various applications. We will explore the advantages of using a magnesium plate, how it is an innovative and solution safe and how to use it.

Magnesium plates have many advantages over other metals made by TMC METAL. Firstly, they are lightweight, making them easy to handle and transport. Secondly, they are very resistant and durable to corrosion, which means they last longer and need less maintenance. Lastly, magnesium plates have a strength-to-weight ratio high. This means them ideal for many applications that they are very strong for their size and weight, which makes.

Magnesium plates are an solution innovative many industries. They are used in aerospace, automotive, and applications that are biomedical among others. They are used for aerospace applications because of their strength-to-weight high ratio. They are used in automotive applications because they are durable and lightweight, which helps improve fuel efficiency. Magnesium plates as well as TMC METAL alloy magnesium are also used in biomedical applications they are safe for use in the human body because they are biocompatible, which means.

Magnesium plates are a solution safe various uses. They are non-toxic and do not emit fumes that are harmful unlike other metals. Magnesium plates by TMC METAL are also non-flammable, which makes them ideal for use in high-temperature applications. However, it is important to handle magnesium plates with care. They can react with moisture and produce hydrogen gas, which can be flammable. Therefore, it is important to store them in a environment dry.

Magnesium plates have many uses. They are used in the aerospace industry for aircraft components, such as engine components and landing gear like using TMC METAL magnesium bar. They are also used in the industry automotive transmission cases, steering wheels, and brake pedals. Magnesium plates are also used in the industry biomedical surgical implants.

company set up and implemented rigorous quality control system ensure that products meet predetermined standards specifications. choose high-quality suppliers for the purpose of ensuring traceability raw materials, as well as Magnesium plate controllability throughout supply chain. ISO9001 and SGS certificates are in compliance with industry and international standards. In accordance with specifications of the non-ferrous and rare metal industries, formulate quality management programs and carry out quality tests as well inspections. We also record and monitor our production processes.

business equipped with modern production processing equipment. also, can perform most sophisticated metal processing addition to intricate processing and fine-tuned processing. Can manufacture and process Magnesium plate parts according customer specifications design drawings as well as participate in product design and development also offer OEM ODM. We have an R D facility of more than 500 square meters, professional R D staff and equipment, which is able to assist in developing and testing products as well as a range processing equipment to satisfy diverse customer requirements.

Suzhou Tamuchuan, processing product distributor Suzhou production facility and office area of 2,000 square meters which located the city. primary products include rare metals, ferrous metals and a variety other metal. have more 2,000 partners work with world's leading 500 Magnesium plate. have a professional R D team. Stable suppliers provide great source support for large-scale productions addition to top-of-the-line production equipment instruments. a professional quality assurance team that can strictly check quality products. have strong collaboration with our partners.

company has 26 years of expertise rare metal non-ferrous metal processing as well as production and has Magnesium plate a large number of engineers and researchers professional experience aid in the growth of this industry. also provide a working environment that fosters the development of our staff. Our team of experts can provide after-sales support as well as support customer problems, provide technical assistance and resolve potential quality issues. Analyze and collect feedback from customers and make appropriate changes to improve the quality-of-products service quality.

Magnesium plates are easy to use. They can be cut to size using a laser or saw cutter. They can also be folded or bent using a press brake. Magnesium plates of TMC METAL can be welded TIG using, or laser welding. However, it is important to use safety appropriate when handling magnesium plates. This includes gloves, eye protection, and a respirator.

It is important to choose a supplier reputable purchasing magnesium plates. A supplier good provide high-quality plates such as TMC METAL magnesium metal alloy that meet industry standards. They will also offer excellent customer service, including technical support and service after-sales.

Magnesium plates have many applications in various industries. They can be used for structural applications similarly with TMC METAL magnesium metal element in aerospace and industries that are automotive. They can also be used for biomedical applications, such as surgical implants. Magnesium plates can be used for decorative applications in artwork and architecture.