Molybdenum and Tungsten: The Marvelous Metals

Are you aware that there are two metals that are superior in quality, durability, and application? Yes, they are the molybdenum and tungsten metals such as TMC METAL tungsten metal. These two types of metals may sound too complex or unfamiliar as a kid, but let us discover what they can do and how they can help us in our daily lives.

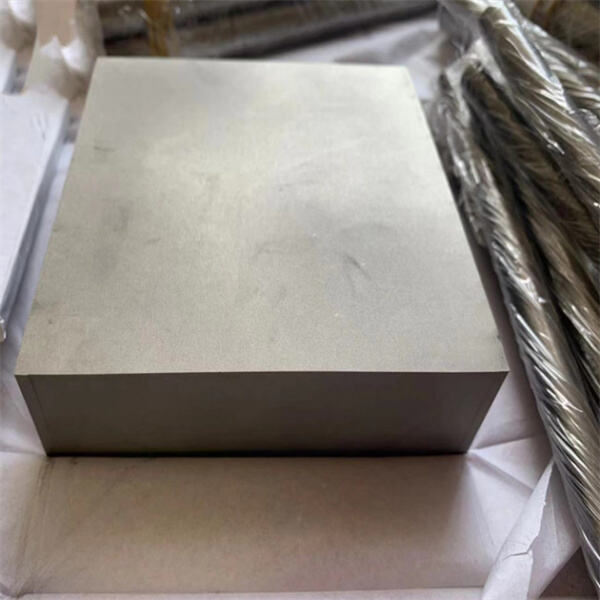

Molybdenum and tungsten of TMC METAL are both elements in the periodic table known for being hard, dense, and heat-resistant metals. They have unique properties used in various industries – from aerospace, nuclear, military, semi-conductors to jewelry and sports. These metals are far more durable than steel and more environmentally friendly since they can be recycled. Here are some of the advantages of molybdenum and tungsten:

1. High melting point: Molybdenum can withstand temperatures as high as 4,750 degrees Fahrenheit, while tungsten can endure up to 6,192 degrees Fahrenheit.

2. Hardness: Both molybdenum and tungsten have high surface hardness, with a mohs scale rating of 5.5 and 7.5, respectively.

3. Corrosion resistance: These metals are non-reactive to water and chemicals, making them less prone to corrosion.

4. Electric conductivity: Tungsten has a high level of electric conductivity that makes it an excellent material for electrical contacts and wires.

The innovation of molybdenum and tungsten and also the TMC METAL tungsten ingot is not only useful but also significantly beneficial in terms of safety. Tungsten has been used to make ammunition for centuries, and these materials have been designed to penetrate through armor. This effectiveness is due to the metals' high densities, which allow increased momentum and penetration power to pass through a surface. Likewise, because of their excellent heat- and radiation-resistant properties, molybdenum and tungsten are used as shields in the nuclear industry, reducing the risks of radiation exposure.

In terms of jewelry, molybdenum alloys, mixed with titanium and stainless steel, are hypoallergenic, making them an excellent material for people with metal allergies. The same goes for tungsten carbide, which is a perfect option for wedding rings because of its durability and resistance to scratching.

Molybdenum and tungsten have various applications, such as:

1. Aerospace and Aircraft: Molybdenum and tungsten are used in the aerospace industry for their high-temperature stability.

2. Electrical components: Tungsten is used as electrical contacts and as a filament in light bulbs.

3. Medical and dental applications: to its corrosion-resistant properties, molybdenum is used for surgical instruments, MRI machines, and cancer treatments.

4. Jewelry and Fashion accessories: Tungsten Carbide like for TMC METAL tungsten tube is a popular material for wedding and engagement rings.

The use of molybdenum and tungsten is versatile, and how to utilize them depends on the intended purpose for each material. For example, molybdenum is mostly made into alloys for its flexibility and pliability, while tungsten remains solid and inflexible.

Molybdenum and tungsten have unique properties that make them the superior option in their respective applications. The quality of these metals is unparalleled when it comes to uses that require durability, strength, and resistance to extreme conditions.

In aerospace and aircraft applications, the high-temperature stability of these metals is essential. TMC METAL Molybdenum is ideal in medical and dental applications because it's highly resistant to corrosion, while tungsten is perfect for electrical components because of its excellent electric conductivity.

Suzhou Tamuchuan a supplier metal processing products located in Suzhou which a production area office space of 22,000 square meters. mainly produce various rare metals as well as a range non-ferrous metals. more than 2,000 partners collaborated world's leading 500 companies. specialized R D team also Molybdenum and tungsten. Stable suppliers can a fantastic source support for large-scale productions as well as top-of-the-line production equipment instruments. professional quality control team ensures that the product is top quality. enjoy a positive collaboration with partners.

company equipped with top-of-the-line production equipment processing equipment can undertake high-end customized metal processing, fine process, and high-difficulty processing. We able produce process metal parts designs and specifications of customer. also Molybdenum and tungsten OEM and ODM. Our research and development center larger than 500 square meters that is staffed professional R D personnel, equipment and facilities can work together in the development of products and testing.

company has established implemented strict quality control process ensure that products conform predetermined standards and specifications. We select suppliers of high-quality in order to guarantee traceability raw materials and the ability control quality Molybdenum and tungsten supply chain. have obtained ISO9001 as well as SGS certifications that are in line with industry standards international standards. In accordance with the specifications of the non-ferrous rare metal industries, our team develops quality management plans and perform quality checks and inspections. We also record and monitor our production processes.

company has over 26 years of experience in manufacturing processing of non-ferrous rare metals. also have educated many engineers scientists with the expertise needed help in development of industry. also provide a platform employees' development. team experts can provide you with after-sales service as well as support customer Molybdenum and tungsten, provide technical support solve potential issues with quality. Take appropriate steps improve quality your products and customer service gathering analyzing feedback from customers.

When it comes to metal fabrication, service is essential in ensuring the consistency and quality of the finished product. You should look for a manufacturer that provides an array of services, from metal processing and prototype developments to proprietary alloys, castings, and custom products. The correct services and assistance can guarantee that the product you receive meets your specific requirements.

Molybdenum and tungsten and also the TMC METAL tungsten alloy are two metals with superior properties that are incredibly useful in various industries and applications. These metals' innovation and implementation into technology are an excellent representation of our society's advancement and progress. We are blessed to have metals that help us improve our quality of life, ensure safety, and enhance the durability of our possessions. It's safe to say that these fantastic metals will continue to play a significant role in technology and our daily lives for centuries to come.