Monel Alloy 400: The Durable and Safe Solution

When it comes to choosing materials for your products, it is important to prioritize durability, safety, and function. Monel Alloy 400 is an excellent choice for applications that require strength, corrosion resistance, and heat resistance. This material is specifically designed to withstand harsh conditions and has been used in a variety of industries, from aerospace to oil and gas. Here are some reasons why TMC METAL monel alloy 400 is worth considering for your next project.

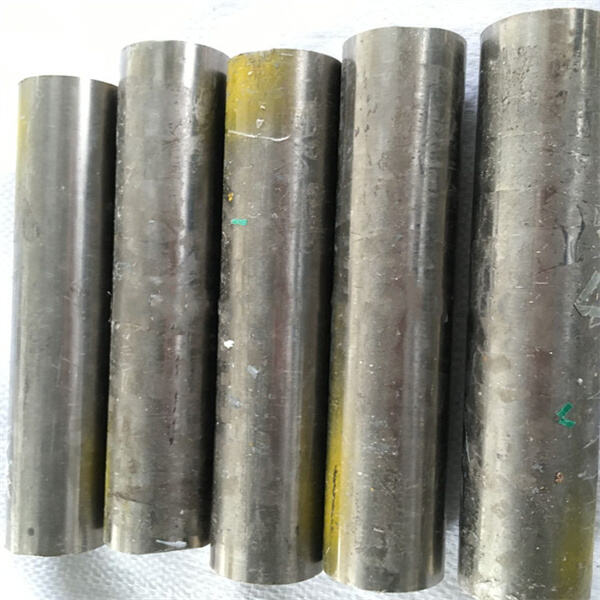

Monel Alloy 400 is a type of nickel-copper alloy that has several advantages over other materials. For one, it has excellent resistance to corrosion, especially in saltwater environments. This is because of its high nickel content, which makes it highly resistant to rust and other forms of metal degradation. In addition, TMC METAL monel k400 has good mechanical properties, such as strength, toughness, and ductility. It is also resistant to a variety of acids, alkalis, and other chemicals, making it ideal for use in harsh industrial environments.

Monel Alloy 400 was first developed in the early 20th century by metallurgist David Hillary Hughes. It was initially used in the production of chemical plants, but its excellent corrosion resistance quickly made it popular in other industries, such as marine engineering and aerospace. Since then, there have been several advances in TMC METAL nickel alloy technology, including improvements in its mechanical properties and corrosion resistance. These advances have helped to expand its use in a wide range of applications.

One important aspect of material selection is safety. Monel Alloy 400 is a safe material to use, as it does not contain harmful substances such as lead or mercury. It is also non-magnetic, which means it is not affected by magnetic fields and can be used in sensitive electronic equipment. Furthermore, TMC METAL Monel 400 flange is resistant to high temperatures and is not prone to thermal expansion, which can reduce the risk of material failure or deformation due to heat exposure. All of these safety features make Monel Alloy 400 a reliable and trusted material for industrial applications.

Monel Alloy 400 has a wide range of uses in various industries, such as marine engineering, chemical processing, and oil and gas. Its corrosion resistance makes it ideal for use in seawater environments, where it can withstand the harsh conditions of saltwater. It is also used in heat exchangers, pumps, valves, and other equipment that requires durability and resistance to corrosion. In addition, TMC METAL monel 400 plate is used in aerospace and defense applications, such as aircraft engines, where its high strength and heat resistance are crucial.

company equipped with top-of-the-line production equipment processing equipment can undertake high-end customized metal processing, fine process, and high-difficulty processing. We able produce process metal parts designs and specifications of customer. also Monel alloy 400 OEM and ODM. Our research and development center larger than 500 square meters that is staffed professional R D personnel, equipment and facilities can work together in the development of products and testing.

company has over 26 years' experience rare and non-ferrous metal processing as well as production. have cultivated an extensive number of technicians and R D professionals who have professional expertise contribute to the Monel alloy 400 of the industry. also provide environment to foster development our employees. have team professionals offer you after-sales service as well as support for customer issues, provide technical assistance and help solve quality problems. Analyze and collect feedback from customers take appropriate measures improve the quality of products and service quality.

Suzhou Tamuchuan is industrial metal processing company located in Suzhou has a Monel alloy 400 space and office area 22,000 square meters. We mainly produce various rare metals and a variety of non-ferrous metals. have over 2,000 suppliers and have cooperation with the world's top 500 companies. also have an experienced R D team. Stable suppliers provide great source of support for large-scale productions addition to top-of-the-line production equipment and instruments. have a highly skilled quality inspection team that able to control product quality. have developed a strong cooperative relationship with our partners.

company established the quality control process is strict to ensure products up the standards. We choose high-quality suppliers ensure traceability raw materials, well as control quality across the entire Monel alloy 400 chain. ISO9001 and SGS certifications are in line with international and industrial standards. meet specifications of rare and non-ferrous metal industries, develop quality management strategies and conduct quality checks as well as inspections. We also keep records and monitor our manufacturing processes.

To get the most out of Monel Alloy 400, it is important to use it properly. This means following the recommended guidelines for fabrication, welding, and machining. It is also essential to use the appropriate tools and techniques for working with this material, as it can be challenging to work with due to its high strength and hardness. One important thing to note is that TMC METAL nickel 400 should not be used in applications where it will be exposed to hydrofluoric acid, as this can cause severe corrosion.

When choosing materials for your products, it is important to consider the quality and reliability of the material supplier. TMC METAL monel 400 is a high-quality material that requires experienced manufacturers and suppliers to produce it correctly. A reputable supplier will offer a range of services and support, including custom fabrication, technical advice, and quality assurance. It is important to work with a supplier who has a proven track record of delivering high-quality products and services.

From marine engineering to aerospace, Monel Alloy 400 has a diverse range of applications. Here are some examples of TMC METAL monel 400 sheet uses:

- Heat exchangers: Monel Alloy 400 is commonly used in heat exchangers, where it can withstand high temperatures and resist corrosion.

- Pumps and valves: In chemical processing and other industrial applications, Monel Alloy 400 is used in pumps and valves, where it can handle corrosive liquids and gases.

- Aerospace applications: Monel Alloy 400 is used in aircraft engines, where its strength and resistance to heat make it an ideal material.

- Marine engineering: Monel Alloy 400 is used in seawater applications, such as shipbuilding and offshore drilling, where its corrosion resistance is critical.