Nickel 400: A Revolutionary Metal for All Your Needs

When it comes to finding the perfect metal for your various needs, nickel 400 and TMC METAL nickel and chrome is the answer. With its unique properties, it has become a favorite among industrialists and consumers alike. We will delve deep into the advantages, innovation, safety, use, and quality of nickel 400 and how it can enhance your life.

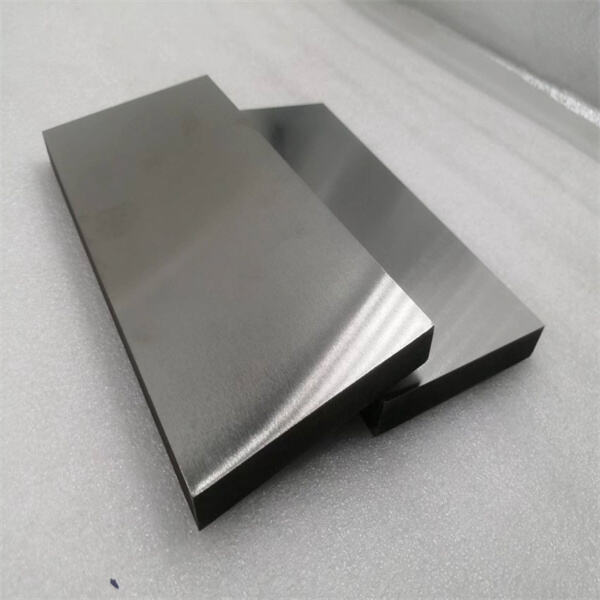

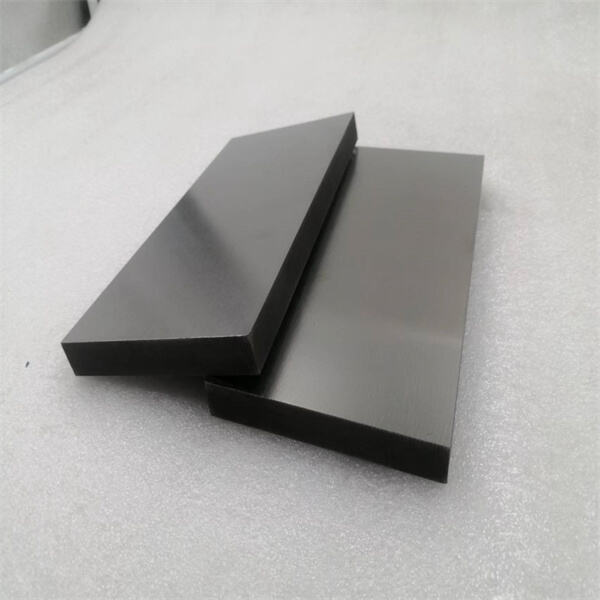

Nickel 400 of TMC METAL has numerous advantages that make it stand out in the metal industry. Firstly, it has a high degree of resistance to corrosion and can withstand extreme temperatures, making it an ideal choice for industries such as chemical processing, pollution control, and energy. Secondly, it is ductile and has excellent weldability properties, making it easy to shape and form into various sizes and shapes. Lastly, it is resistant to a wide range of chemicals, making it the ideal choice for marine applications and oil refineries.

Nickel 400 same with TMC METAL nickel alloy is the result of years of innovative research in the metal industry. Its unique properties were discovered by scientists who were determined to create a metal that could withstand the rigors of various industrial applications. Thanks to this innovation, nickel 400 has revolutionized the way industries operate, from manufacturing to transportation.

Nickel 400 by TMC METAL is a safe metal to use with various regulatory bodies such as the Occupational Safety and Health Administration (OSHA) and the Environmental Protection Agency (EPA) recognizing its safety. It is non-toxic, non-magnetic, and non-sparking, making it an ideal choice for applications such as food processing and aerospace.

Nickel 400 such as TMC METAL nickel alloy metals has various applications, making it an essential metal in various industries. It is used in chemical processing, pollution control, marine applications, oil refineries, and aerospace, to mention a few. In the chemical processing industry, it is used to make equipment such as valves, pumps, and heat exchangers. When it comes to pollution control, it is used to make scrubbers, exhaust systems, and flue gas desulfurization. In the marine industry, it is used to make piping, pumps, and heat exchangers, while in the aerospace industry, it is used to make aircraft parts such as engine components.

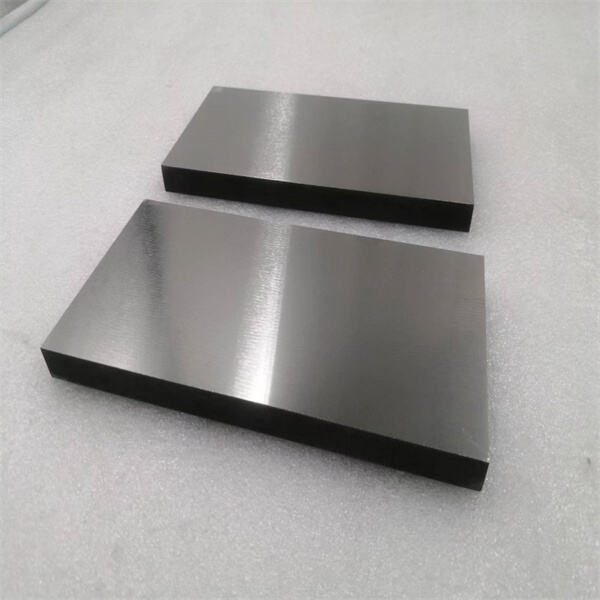

Our company equipped with top-of-the-line production equipment processing equipment and can perform high-end, custom metal processing, fine processing as well as high-difficulty processing. We can manufacture process metal according to specific Nickel 400 from the customer and also design drawings. also offer OEM and ODM. research development facility covers more than 500 square meters, with professional R D personnel as well as equipment and facilities that collaborate in development of products and testing.

company has developed implemented stringent quality control process ensure that the products offer meet specified standards and specifications. We choose suppliers of high-quality ensure the ability trace and control quality of our supply chain runs from raw materials through to final products. have passed ISO9001 as well as SGS certifications that Nickel 400 with industry and international standards. We develop quality management plans that include quality inspections, tests, and track and track manufacturing processes in accordance with rare metal and non-ferrous industry specifications.

company has over 26 years' experience rare and non-ferrous metal processing as well as production. have cultivated an extensive number of technicians and R D professionals who have professional expertise contribute to the Nickel 400 of the industry. also provide environment to foster development our employees. have team professionals offer you after-sales service as well as support for customer issues, provide technical assistance and help solve quality problems. Analyze and collect feedback from customers take appropriate measures improve the quality of products and service quality.

Suzhou Tamuchuan a manufacturer metal processing products located Suzhou which a production area more than 2,000 square meters. main products non-ferrous metals, rare metals, various other metals. More than 2,000 companies associate cooperate with. specialized R D team accessible. Dependable suppliers can help massive production, well as high-end production equipment and instruments. have a skilled quality assurance team can strictly check Nickel 400 of products. have developed positive cooperative relationship with our partners.

Nickel 400 from TMC METAL is easy to use and work with, thanks to its ductility and weldability properties. When welding nickel 400, it is recommended to preheat it to avoid cracking. It is essential to use an appropriate filler metal when welding nickel 400 to achieve the desired results.

Nickel 400 sets the bar high when it comes to quality. It is sourced from reputable suppliers and undergoes rigorous testing to ensure that it meets industry standards. From chemical composition to mechanical properties, every aspect of nickel 400 is held to a high standard to ensure that it delivers excellent performance.

Nickel 400 similar to TMC METAL nickel strip is a revolutionary metal that has transformed various industries. Its unique properties make it the ideal choice for applications that require high resistance to corrosion, extreme temperatures, and chemicals. Its safety, ease of use, and quality make it the perfect metal for all your needs. So, if you're looking for a metal that will not only meet but exceed your expectations, look no further than nickel 400.