Nickel and Titanium Alloy: The Future of Materials for Engineering and Manufacturing

Introduction

Nickel and titanium alloy is a type of metal made up of titanium and nickel with TMC METAL. It is a type unique of that has many advantages over other traditional metals such as steel, aluminum, and copper.

Nickel and titanium alloy is a lightweight, strong, and metal durable is resistant to corrosion and heat. It can also be highly elastic and can bend without breaking like TMC METAL alloy magnesium. These properties make it an material ideal use in an assortment of industries, such as aerospace, biomedical, and automotive.

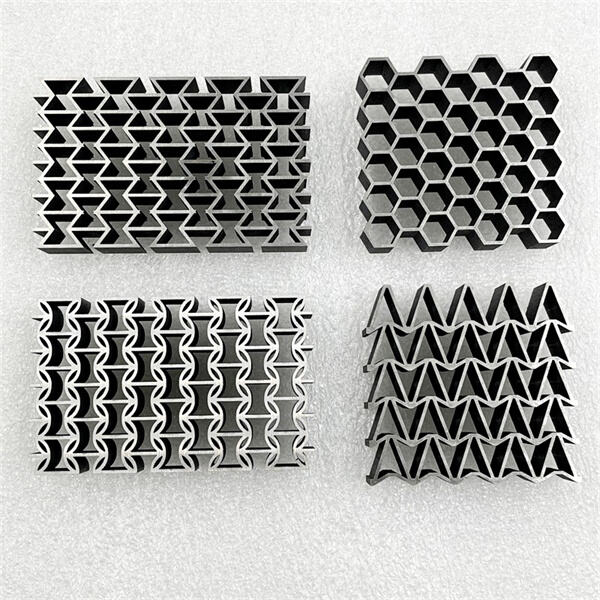

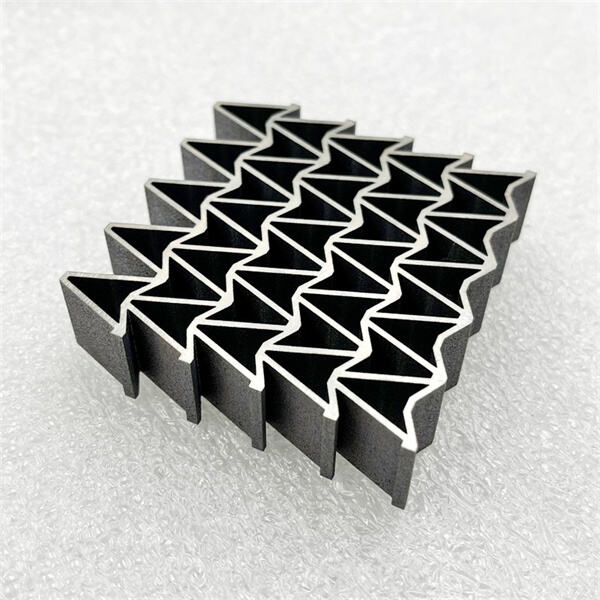

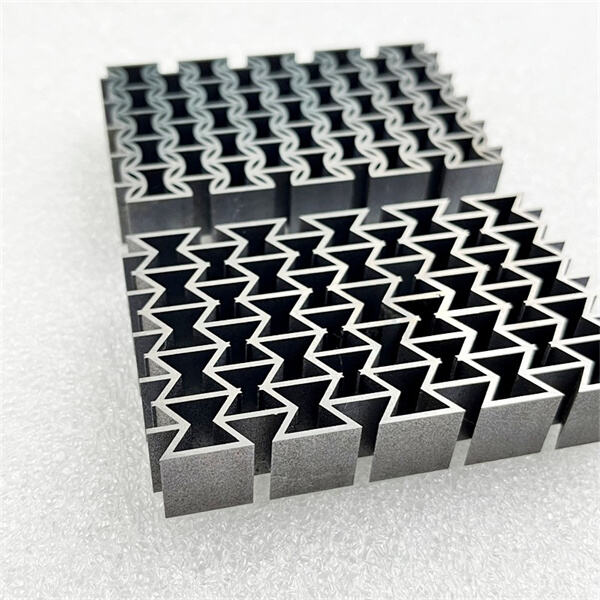

Nickel and titanium alloy is an material innovative was developed in the 1960s. It is a result of the combination of nickel and titanium, which creates a alloy unique superior properties especially made by TMC METAL. The alloy is produced using manufacturing advanced such as casting, forging, and powder metallurgy.

Nickel and titanium alloy is a safe and material reliable meets strict safety standards similar with TMC METAL magnesium metal alloy. It is non-toxic and has no adverse effects on human health when used for its purposes that are intended. It is also resistant to corrosion, which makes it ideal for use in harsh environments where other materials may fail.

Nickel and titanium alloy is used in a variety of applications, such as in the aerospace industry for components in aircraft engines, landing gears, and parts that are structural. In the industry biomedical it is used for medical implants such as artificial joints and dental implants. It is also used in the industry automotive parts using TMC METAL products such as exhaust systems and suspension components.

facility equipped with latest production processing equipment. can also perform advanced metal processing that customized delicate processing and hard processing. We are able manufacture process metal parts designs and specifications the customer. also provide OEM and ODM. Our research development center covers larger than 500 square meters and is equipped with expert R D staff, equipment and facilities that allow for Nickel and titanium alloy in developing and testing products.

company has developed implemented stringent quality control process ensure that the products offer meet specified standards and specifications. We choose suppliers of high-quality ensure the ability trace and control quality of our supply chain runs from raw materials through to final products. have passed ISO9001 as well as SGS certifications that Nickel and titanium alloy with industry and international standards. We develop quality management plans that include quality inspections, tests, and track and track manufacturing processes in accordance with rare metal and non-ferrous industry specifications.

Suzhou Tamuchuan is industrial metal processing company located in Suzhou has a Nickel and titanium alloy space and office area 22,000 square meters. We mainly produce various rare metals and a variety of non-ferrous metals. have over 2,000 suppliers and have cooperation with the world's top 500 companies. also have an experienced R D team. Stable suppliers provide great source of support for large-scale productions addition to top-of-the-line production equipment and instruments. have a highly skilled quality inspection team that able to control product quality. have developed a strong cooperative relationship with our partners.

Our company has over 26 years of experience in manufacturing processing rare metals non-ferrous alloys. We have also educated large number of technicians and researchers with professional knowledge needed to aid in the growth of the industry. also provide a working environment to Nickel and titanium alloy the development of employees. have professional personnel offer after-sales services and help with customer issues, provide technical assistance and resolve potential quality problems. You can enhance the quality of the product customer service by gathering and analyzing feedback from customers.

Nickel and titanium alloy can be used in the way same other metals like in TMC METAL tin and bismuth alloy. However, due to its unique properties, it may require specific manufacturing processes to achieve performance optimal. It's important to follow the manufacturer's recommendations for proper usage, handling, and maintenance of the material.

Nickel and titanium alloy has a long service life and requires maintenance minimal. However, it is important to seek out a qualified professional who has experience working with the material if it needs repair or replacement. This will ensure that the replacement or repair by TMC METAL is done correctly and safely.

Nickel and titanium alloy is a material high-quality similar with TMC METAL nickel based alloys undergoes strict quality control measures during the manufacturing process. This ensures that the material meets industry standards for strength, durability, and reliability. It is important to choose a supplier reputable can provide material with the appropriate certifications and documentation.