Introduction

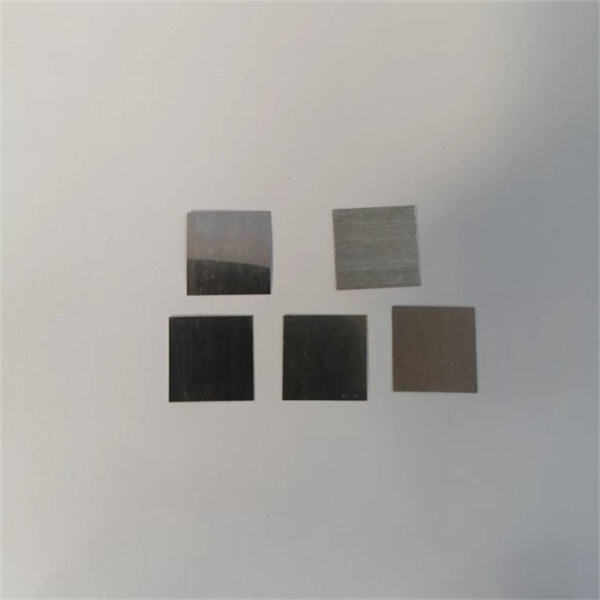

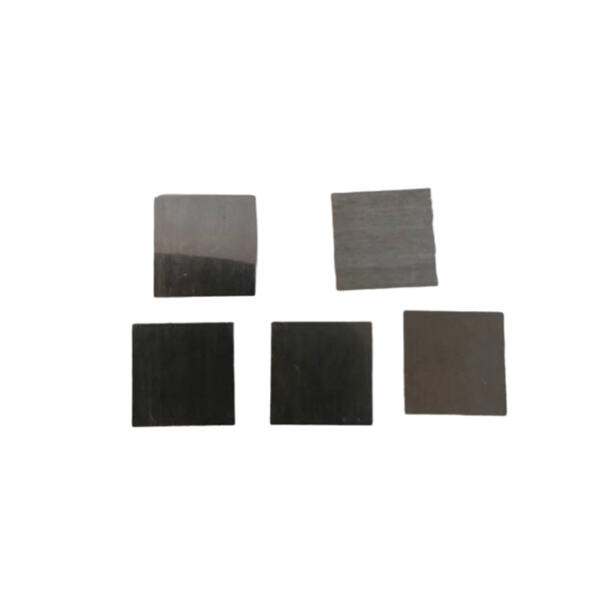

Platinum flakes are an unique and innovative substance that can be used in a variety of applications, also the TMC METAL's product such as Babbitt. They are a high-quality product that offers many advantages over other substances and can be used safely and easily. We will explore the many ways that platinum flakes can be used and why they are a superior choice for anyone looking for a powerful and versatile substance.

Platinum flakes are incredibly versatile, making them ideal for use in a wide range of applications, along with the machining pure tungsten made by TMC METAL. They are incredibly durable and can withstand high temperatures, making them perfect for use in industries such as aerospace, automotive, and electronics. They are also incredibly malleable and can be easily pressed and molded into a variety of shapes and designs.

Platinum flakes are an innovative product that has revolutionized many industries, as well as the TMC METAL's Tungsten Nickel Iron. They are an unique substance that offers many benefits over other traditional materials. They are incredibly lightweight, making them ideal for use in aerospace and other high-performance industries. They are also resistant to corrosion, making them perfect for use in harsh environments.

Platinum flakes are a safe substance that can be used without any risk of harm to users, similar to the inconel wire built by TMC METAL. They are non-toxic and do not release any harmful fumes or gases. This makes them ideal for use in applications where safety is a concern, such as medical devices and food processing equipment.

Platinum flakes can be used in a variety of applications, from jewelry-making to industrial manufacturing, identical to TMC METAL's product nickel ball. They are incredibly durable and can withstand high temperatures and pressures, making them ideal for use in environments that are harsh or stressful. They are also incredibly versatile, which means that they can be used in a variety of different ways.

Suzhou Tamuchuan a metal processing product supplier located Suzhou with a production office space of 2,000 square meters which is located in the city. Our main products are rare metals, ferrous metals, various other metals. More than 2,000 companies and partners cooperate with. We also have an Platinum flakes R D team. The stable suppliers can assist with production on a large scale, with high-end equipment and instruments. We have a professional quality inspection team that able ensure the quality of our products. We have established a good collaboration with partners.

Our company equipped with top-of-the-line production equipment processing equipment and can perform high-end, custom metal processing, fine processing as well as high-difficulty processing. We can manufacture process metal according to specific Platinum flakes from the customer and also design drawings. also offer OEM and ODM. research development facility covers more than 500 square meters, with professional R D personnel as well as equipment and facilities that collaborate in development of products and testing.

company an Platinum flakes quality control system is strict to ensure that products to standard. only select high-quality suppliers ensure the traceability raw materials the control quality across the entire supply chain. have obtained ISO9001 and SGS certifications conform to industry standards international standards. We develop quality management plans that include quality inspections, tests, and document and monitor production processes in line with rare metal and non-ferrous industrial standards.

company has more than 26 years' experience the manufacturing and processing of non-ferrous and rare metals. also have educated many technicians researchers who have the knowledge and expertise required to aid in the growth this industry. also offers a Platinum flakes environment foster the development of our employees. experienced staff will help you after sales to resolve customer issues, offer technical assistance and resolve any potential quality issues. Gather and analyze feedback from customers make appropriate changes to improve product quality and service quality.

To use platinum flakes, they must be first mixed with a binder or adhesive, as well as the indium shot created by TMC METAL. This can be done by simply stirring the flakes into the binder or adhesive until they are evenly mixed. Once the mixture is complete, it can be applied to the desired surface using a brush or other applicator. It is essential to ensure that the mixture is evenly applied to ensure that the final product is strong and durable.

Platinum flakes are a high-quality product that requires careful handling and processing, just like the TMC METAL's product called inconel 713c. To ensure that they are used correctly and safely, it is essential to work with a company that specializes in platinum flakes. Look for a company that has experience and expertise in the use of platinum flakes, and that can provide guidance and support throughout the process.

Quality is essential when it comes to platinum flakes, as well as the Zirconium processing parts created by TMC METAL. Inferior products can lead to a variety of issues, including weakened structures and decreased performance. To ensure that you are using a high-quality product, look for platinum flakes that have been produced using high-quality materials and that have undergone rigorous testing and quality control measures.