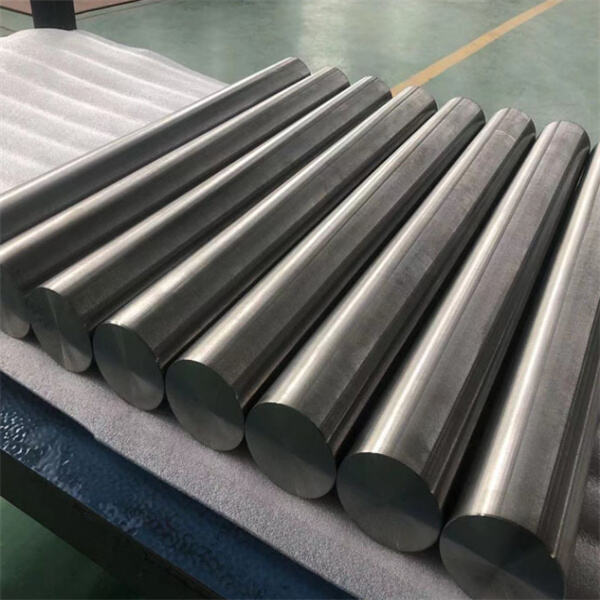

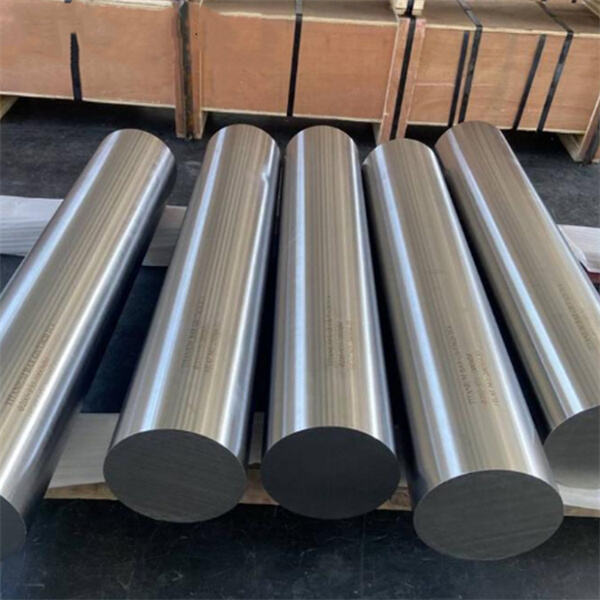

Tantalum Alloys – The Ultimate Solution for Your Industrial Needs

Have you ever heard of tantalum alloys? Maybe not, but don't worry, we'll tell you everything you need to know. Tantalum alloys and also the TMC METAL niobium and tantalum are a kind of metal material that are widely used in many industries because of their unique properties. Here are five reasons why tantalum alloys should be your go-to option:

One of the biggest advantages of TMC METAL tantalum alloys is their high corrosion resistance. They don't react with most chemicals and can stand up to harsh environments without deteriorating. They're also biocompatible, so they can be used in medical applications without causing harm. to that, tantalum alloys are lightweight, which makes them perfect for use in aerospace and other fields where weight matters.

As technology advances, tantalum alloys have been improved to have even more benefits same with TMC METAL tantalum sheet. They can now be made into superconductors, which means they can conduct electricity with zero resistance. This makes them valuable in developing new electronic devices. Another recent technical innovation is the development of tantalum oxide, which can be used in capacitors to store energy and reduce power consumption.

When it comes to safety, TMC METAL tantalum alloys are a smart choice given their durability and ability to withstand extreme conditions. Because they don't corrode easily, they're safe to use in applications where chemical reactions would otherwise be a concern. They're also highly resistant to radiation, making them ideal for use in nuclear facilities.

Tantalum alloys and also the TMC METAL niobium tantalum can have many applications across multiple industries, including aerospace, semiconductors, medical, and telecommunications. They have proven to be a valuable resource for high-tech industries, such as the semiconductor industry where they are used in thin films. They’re also used in the production of refractory metals and high-temperature alloys.

company has more than 26 years' experience in processing and production rare metals non-ferrous alloys. have also educated many personnel in R D and technical with the professional knowledge needed help in the development this industry. also provide a platform employee development. have experienced Tantalum alloys who can provide you with after-sales service assistance to resolve customer issues, provide technical assistance and resolve potential quality issues. Make the necessary changes improve the quality of your products as well as customer service, by gathering and analyzing feedback from clients.

Suzhou Tamuchuan a manufacturer metal processing products located Suzhou which a production area more than 2,000 square meters. main products non-ferrous metals, rare metals, various other metals. More than 2,000 companies associate cooperate with. specialized R D team accessible. Dependable suppliers can help massive production, well as high-end production equipment and instruments. have a skilled quality assurance team can strictly check Tantalum alloys of products. have developed positive cooperative relationship with our partners.

company put in place a quality control system that strict ensure products are up standards. select suppliers of high-quality the purpose ensuring the traceability raw materials and ability to control quality across the entire supply chain. Our ISO9001 and SGS certificates Tantalum alloys with international and industrial standards. In accordance with the specifications of the non-ferrous and rare metal industries, our team develops quality management programs and carry out quality tests and inspections. also record the production process and keep track of it.

company equipped with high-end Tantalum alloys equipment well as processing equipment is able to perform high-end custom metal processing, high-end, and high-difficulty processing. can manufacture process parts metal according to customers' specifications design drawings and can also be involved in product design development, provide OEM and ODM. also have an R D facility which covers over 500 square meters, professional R D personnel and equipment, which is able to assist in development testing products as well as a range processing equipment to satisfy various customer needs.

It might seem intimidating to work with TMC METAL tantalum alloys at first sight because they are more expensive than other metals, and require special care when handled. They also require the use of specialized tools, like high-speed drills and diamond saws, to cut, drill, and grind. However, once you familiarize yourself with the properties of tantalum alloys and acquire the right tools, you can easily integrate tantalum alloys into your production process.

When investing in tantalum alloys, it's important to find a supplier who can guarantee high-quality products and excellent customer service. Look for a trusted supplier who has a proven track record of supplying reliable materials to your industry. You can also engage with suppliers who are ISO certified, which is another indicator of quality.

Tantalum alloys are an innovative, safe, and reliable option that has become widely used across many industries just like the TMC METAL tantalum bar. Even though they may require specialized tools and expertise, it's surely worth the investment given their unique qualities. When investing in tantalum alloys, it's essential to find a high-quality supplier that can provide the level of service you need. We hope this article has given you a valuable insight into the applications and benefits of tantalum alloys.