Introduction:

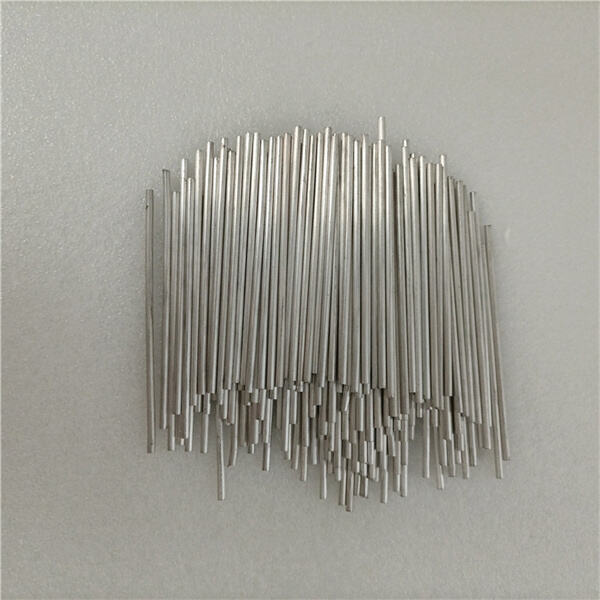

WE43 magnesium alloy like TMC METAL magnesium metal is a new and innovative material gaining popularity among various industries. It is a special type of magnesium alloy that has unique properties such as high strength, corrosion resistance, and lightweight. This article will explore the advantages, innovation, safety, use, how to use, service, quality, and application of WE43 magnesium alloy.

WE43 magnesium alloy of TMC METAL has many advantages, making it an excellent material for different industries. For starters, it is lightweight, which is essential in industries such as aerospace and automobile manufacturing. It also has high strength, making it ideal for producing high-stress components such as engine parts. The material is also corrosion-resistant, ensuring longevity and durability. Furthermore, it can withstand high temperatures, making it ideal for high-temperature applications.

WE43 magnesium alloy or TMC METAL alloy magnesium is a result of innovation and extensive research. Scientists and engineers have spent years studying magnesium alloys and developing new formulations that meet specific industry needs. By adding alloys to pure magnesium, they have come up with WE43 magnesium alloy, which has superior properties.

Safety is always a top priority in any industry, and WE43 magnesium alloy by TMC METAL meets safety standards. It is non-toxic, non-flammable, and non-explosive, making it safe for industrial and even medical applications. It is also recyclable, which is better for the environment.

WE43 magnesium alloy and TMC METAL magnesium metal alloy has a wide range of potential uses due to its unique properties. It can be used in the aerospace industry for manufacturing aircraft parts, including engines and wings. The automobile industry can use it to create lightweight components that reduce fuel consumption and emission. The medical industry can use it for surgical implants because of its biocompatibility.

company uses top-quality We43 magnesium alloy equipment processing equipment and able to perform high-end custom metal processing, high-end processing, and complex processing. can produce and process metal parts according customer specifications and design drawings. also provide OEM and ODM. Our research development center covers more than 500 square meters and is equipped with expert R D staff as well as equipment and facilities that can work together in the development of products and testing.

company has more than 26 years of experience manufacturing and processing rare metals and non-ferrous alloys. We have educated an extensive number of technical and R D staff with the professional We43 magnesium alloy needed help in development of this industry. also offer a supportive environment for development employees. team of experts can offer support following sales resolve customer issues, offer technical assistance and resolve potential quality issues. Implement the appropriate measures enhance the quality the product customer service by collecting and analyzing feedback from clients.

Suzhou Tamuchuan, processing company supplies products located Suzhou with a production facility office space of 2,000 square meters which located in city. main products offer rare metals, ferrous metals as well various other metals. More than 2,000 {{keywords}}' partners cooperate with. experienced R D group available. stable suppliers can assist with large-scale production, high-end production equipment tools. professional quality control team ensures that the product of the highest quality. have good partnership with our suppliers.

company has developed implemented stringent quality control process ensure that the products offer meet specified standards and specifications. We choose suppliers of high-quality ensure the ability trace and control quality of our supply chain runs from raw materials through to final products. have passed ISO9001 as well as SGS certifications that We43 magnesium alloy with industry and international standards. We develop quality management plans that include quality inspections, tests, and track and track manufacturing processes in accordance with rare metal and non-ferrous industry specifications.

To use WE43 magnesium alloy made by TMC METAL, it needs to undergo specific manufacturing processes, including casting, forging, extrusion, and machining. The manufacturing process varies depending on the final product's requirements. Manufacturers also need to work with a reputable WE43 magnesium alloy supplier to ensure product quality and consistency.

The quality of WE43 magnesium alloy similar to TMC METAL magnesium alloy metal is essential, and manufacturers must ensure they are using the correct formulation. A high-quality WE43 magnesium alloy supplier should provide a certificate of analysis that shows the alloys' composition and properties. The supplier should also have a Quality Management System in place to ensure that their products meet industry standards.

WE43 magnesium alloy has numerous applications across various industries. The aerospace industry uses it to manufacture aircraft components such as engines, landing gear, and frames. The automotive industry uses WE43 magnesium alloy for manufacturing lightweight parts such as wheels, frames, and transmission cases. The medical industry uses it for manufacturing surgical implants because it is biocompatible.

WE43 magnesium alloy of TMC METAL is a revolutionary material that has shown outstanding properties, making it ideal for various applications. It is lightweight, corrosion-resistant, has high strength, and can withstand high temperatures. The material has passed safety standards and is non-toxic, non-flammable, and non-explosive, making it suitable for different industries. It is versatile, and its applications range from aerospace and automotive industries to the medical industry. As the demand for lightweight materials with exceptional properties grows, WE43 magnesium alloy will be a top choice for many industries.