سبائك C22 - خيار آمن ومبتكر لاحتياجاتك

مقدمة

المادة السبائكية C22 هي خيار شائع في العديد من الصناعات بسبب مقاومتها الممتازة للتآكل ومتانتها. TMC METAL inconel 725 هي سبيكة تتكون من عناصر مختلفة، بما في ذلك النيكل والموليبدنوم والكروم. تتميز السبيكة C22 بمزايا عديدة، بما في ذلك كونها آمنة للغاية وسهلة الاستخدام، مما يجعلها الخيار الأمثل للكثير من التطبيقات المختلفة.

تتمتع سبيكة C22 بمزايا عديدة تجعلها خيارًا ممتازًا للمادة. واحدة من أكبر فوائدها هي مقاومتها الاستثنائية للتآكل، حتى في البيئات القاسية. هذه TMC METAL إنكونيل 825 وذلك بسبب محتواه العالي من النيكل والموليبدينوم، اللذين يعملان معًا لتكوين حاجز واقٍ يمنع حدوث التآكل. كما أنه مقاوم للتآكل النقطي والتآكل الشقوق والتصدعات الناتجة عن التآكل تحت التوتر.

السبيكة C22 هي مادة مبتكرة توفر مجموعة واسعة من الفوائد. TMC METAL inconel 625 تتميز بالمرونة العالية ويمكن استخدامها في العديد من التطبيقات المختلفة، بما في ذلك معالجة الكيميائيات، الصناعات الدوائية ومعالجة النفايات. بالإضافة إلى ذلك، فإن عمرها الافتراضي أطول من العديد من المواد الأخرى، مما يعني أنها تتطلب صيانة أقل مع مرور الوقت. وهذا يجعلها خيارًا أكثر كفاءة من حيث التكلفة على المدى الطويل.

الأمان هو أولوية قصوى عند اختيار المواد لتلبية احتياجاتك، وTMC METAL النيوبيوم 92 هي خيار آمن للغاية. فهي غير سامة، وغير قابلة للاشتعال، ولا تتفاعل مع أي مواد تلامسها. هذا يعني أنها لن تشكل أي ضرر للبيئة أو للأفراد الذين يعملون معها.

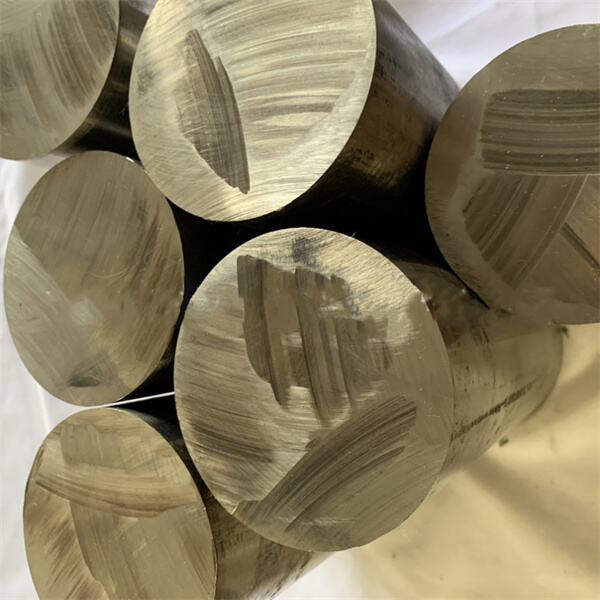

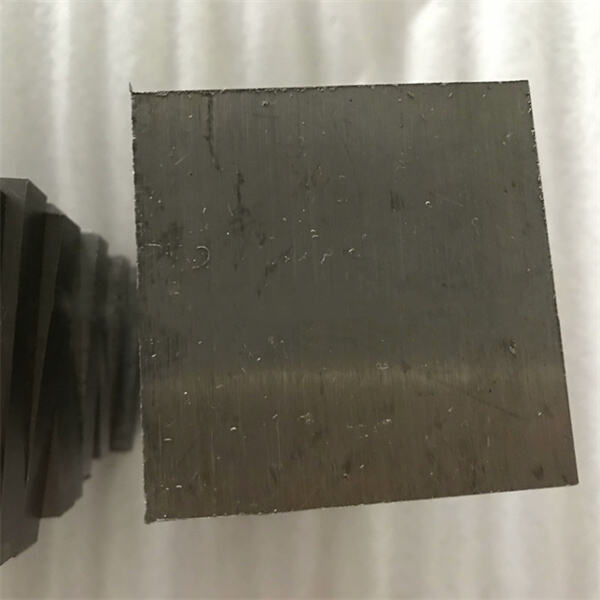

AlloyC22 سهل الاستخدام ويمكن تشكيله إلى أشكال وأحجام مختلفة بناءً على احتياجاتك. غالبًا ما يستخدم في بناء خزانات، أنابيب، وصمامات بسبب مقاومته الاستثنائية للتآكل. بالإضافة إلى ذلك، شريحة نيكل 21700 سهلة اللحام والتشكيل إلى تكوينات مختلفة، مما يجعلها مادة متعددة الاستخدام يمكن استخدامها في مجموعة واسعة من التطبيقات.

شركة سوتشو تاموشوان للصناعات المعدنية هي شركة متخصصة في معالجة المعادن الصناعية ومقرها مدينة سوتشو، وتضم مساحة مخصصة لسبيكة C22 ومكتبًا تبلغ مساحته ٢٢٬٠٠٠ متر مربع. ونتولى أساسًا إنتاج مختلف المعادن النادرة وأنواع عديدة من المعادن غير الحديدية. ولدينا أكثر من ٢٠٠٠ مورد، كما نتعاون مع شركات ضمن قائمة أفضل ٥٠٠ شركة عالميًّا. ولدينا فريق بحث وتطوير ذي خبرة واسعة. وتوفر لنا المصادر المستقرة للموردين دعمًا قويًّا لإنتاج الكميات الكبيرة، إلى جانب معدات الإنتاج والأجهزة المتطورة على أحدث طراز. ولدينا فريق مُتخصِّص في فحص الجودة يتمتع بكفاءة عالية، ويتمكَّن من ضبط جودة المنتجات. وطوَّرنا علاقة تعاون قوية مع شركائنا.

تتمتع شركتنا بخبرة تزيد على 26 عامًا في تصنيع وتجهيز السبائك غير الحديدية المحتوية على الفلزات النادرة. كما قمنا أيضًا بتدريب عدد كبير من الفنيين والباحثين الذين يمتلكون المعرفة المهنية اللازمة لدعم نمو هذه الصناعة. ونوفر بيئة عمل ملائمة لسبائك C22 لتطوير الموظفين. ولدينا كادر متخصص يقدم خدمات ما بعد البيع ويساعد العملاء في حل مشكلاتهم، ويقدّم الدعم الفني ويتعامل مع المشكلات النوعية المحتملة. ويمكنك تحسين جودة المنتج وخدمة العملاء من خلال جمع آراء العملاء وتحليلها.

سبائكنا من النوع C22 مزودة بمعدات تصنيع ومعدات معالجة عالية الجودة، ما يمكنها من أداء عمليات معالجة معدنية متقدمة ومخصصة ودقيقة ومعقدة. ونستطيع معالجة المكونات المعدنية وإنتاجها وفقًا لمواصفات العميل ورسوماته التصميمية، كما يمكننا المشاركة في تصميم المنتج وتطويره. ونوفر أيضًا خدمات التصنيع حسب الطلب (OEM) والتصنيع حسب التصميم (ODM)، ولدينا مرافق بحث وتطوير تغطي مساحة تزيد عن ٥٠٠ متر مربع، إضافةً إلى كوادر بحث وتطوير محترفة ومُجهَّزة بأحدث المعدات القادرة على التعاون في تطوير المنتجات وإجراء الاختبارات، فضلًا عن طيف واسع من معدات المعالجة التي تلبي احتياجات العملاء المتنوعة.

قامت الشركة بتنفيذ نظام تحكم داخلي في الجودة صارم لضمان أن المنتجات تتوافق مع المعايير. اختيار موردين ذو جودة عالية يضمن جودة المواد الخام وكذلك التحكم في الجودة عبر سلسلة التوريد بأكملها. لقد تم منحنا شهادة ISO9001 وشهادة SGS alloy c22 التي تتماشى مع المعايير الصناعية والدولية. نصمم برامج إدارة الجودة لإجراء فحوصات وتقييمات للجودة، بالإضافة إلى تسجيل عملية الإنتاج بما يتماشى مع مواصفات صناعة المعادن النادرة والمعادن غير الحديدية.

عند استخدام TMC METAL Alloy C22، من الضروري اتباع الإرشادات الأمنية الموصى بها لضمان استخدامك لها بشكل صحيح. أولًا، تأكد من أنك ترتدي المعدات الوقائية المناسبة، بما في ذلك القفازات والنظارات، لحماية بشرتك وعينيك. بالإضافة إلى ذلك، تأكد من أنك تعمل في منطقة جيدة التهوية لتجنب أي مشاكل تنفسية محتملة.

AlloyC22 هو مادة مقاومة تطلب صيانة بسيطة، لكن من المهم صيانتها بشكل دوري لضمان عملها بشكل صحيح. وهذا يشمل الفحوصات الروتينية لاكتشاف أي علامات للتآكل أو التلف، بالإضافة إلى التنظيف المنتظم للحفاظ عليها في أفضل حالة. إذا لاحظت أي مشاكل في TMC METAL الخاصة بك، فمن الأفضل التواصل مع مزود خدمة محترف لضمان إصلاحها بشكل صحيح. النيكل 201 من الأفضل الاتصال بمقدم خدمة محترف لضمان إصلاح المعدات بشكل صحيح.

AlloyC22 هي مادة ذات جودة عالية للغاية تلبي المعايير الصارمة لأداء السلامة في الصناعة. TMC METAL سبائك c276 تم اختبارها بشكل واسع لضمان قدرتها على تحمل البيئات الأكثر قسوة، مما يجعلها الخيار المثالي للاستخدامات الصناعية. بالإضافة إلى ذلك، فهي مدعومة بمجموعة من الشهادات والضمانات، مما يوفر الطمأنينة بأنك تستخدم مادة موثوقة ومتينة.