- خيار متين وآمن لجميع احتياجاتك&l...">

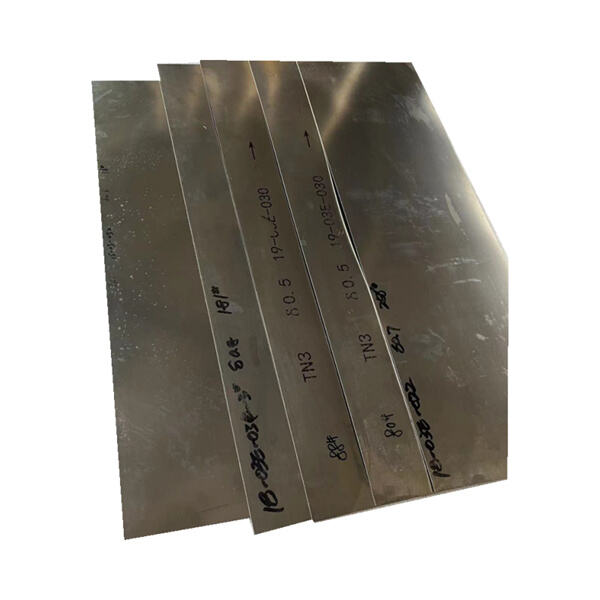

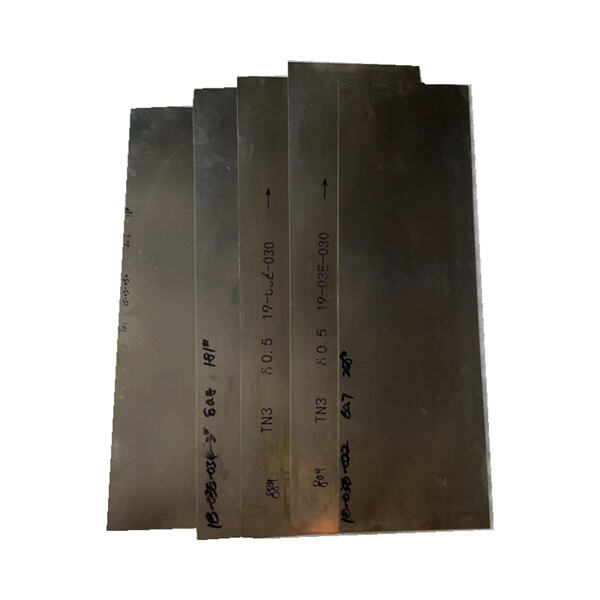

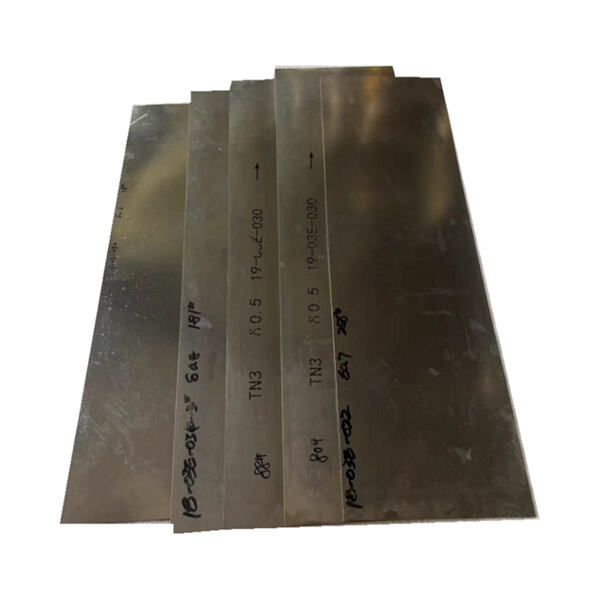

ألواح سبائك النيكل و TMC METAL مسحوق النيكل هي نوع من الألواح المعدنية المصنوعة من مزيج من النيكل ومعادن أخرى مثل النحاس والكروم والحديد. إنها خيار مستدام وأمن للاستخدام في مختلف الأغراض الصناعية والمنزلية.

للوحة السبيكة النيكلية من TMC METAL عدة مزايا على أنواع أخرى من ألواح المعدن. فهي مقاومة للغاية للتآكل، مما يجعلها الخيار المثالي للمنتجات التي تلامس المواد الكيميائية القاسية أو المياه المالحة. بالإضافة إلى ذلك، فإن لوحة سبيكة النيكل غير مغناطيسية، مما يوفر خيارًا أكثر أمانًا للمعدات الحساسة والأجهزة الطبية.

الابتكار في لوحة سبيكة النيكل المشابهة لـ TMC METAL شريط نيكل أدى إلى تطوير سبائك جديدة ومحسّنة تتمتع بخصائص أفضل. صُممت هذه السبائك لتحمل درجات الحرارة العالية والضغط والارتداء، مما يجعلها مثالية للاستخدام في ظروف قاسية.

تعتبر لوحة سبيكة النيكل من TMC METAL آمنة للاستخدام في مختلف التطبيقات لأنها لا تحتوي على أي مواد ضارة. كما أنها خالية من أي مواد سامة مثل الرصاص، مما يجعلها مثالية للاستخدام في الصناعات الغذائية والدوائية.

سوزهو تاموتشوان، مورد لمنتجات معالجة المعادن يقع في سوتشو، ويضم مكتب إنتاج بمساحة 2000 متر مربع داخل المدينة. منتجاتنا الرئيسية هي المعادن النادرة، والمعادن الحديدية، وجميع أنواع المعادن الأخرى. نتعاون مع أكثر من 2000 شركة وشريك. كما لدينا فريق بحث وتطوير متخصص في ألواح سبائك النيكل. يمكن للموردين المستقرين دعمنا في الإنتاج على نطاق واسع باستخدام معدات وأجهزة متقدمة. لدينا فريق احترافي لفحص الجودة قادر على ضمان جودة منتجاتنا. وقد أنشأنا تعاوناً جيداً مع الشركاء.

المنشأة مجهزة بأحدث معدات معالجة الإنتاج. يمكنها أيضًا تنفيذ معالجة معدنية متقدمة تشمل المعالجة الدقيقة المخصصة ومعالجة المواد الصلبة. نحن قادرون على تصنيع ومعالجة أجزاء معدنية وفقًا للتصاميم والمواصفات التي يحددها العميل. كما نوفر أيضًا التصنيع حسب الطلب (OEM) وتصنيع التصميم الخاص (ODM). مركز البحث والتطوير لدينا يغطي أكثر من 500 متر مربع ومزود بفريق من الخبراء في البحث والتطوير، والمعدات والمرافق التي تمكننا من تطوير واختبار منتجات اللوحات السبائكية النيكل.

الشركة لديها خبرة تزيد عن 26 عامًا في تصنيع وتجهيز المعادن النادرة والسبائك غير الحديدية. وقد درّبت عددًا واسعًا من الكوادر الفنية وموظفي البحث والتطوير، الذين قدّموا الدعم اللازم باستخدام صفائح سبائك النيكل المهنية لتطوير هذه الصناعة. كما نقدّم بيئة داعمة لتنمية الموظفين. ويمكن لفريق الخبراء لدينا تقديم الدعم بعد البيع لحل مشكلات العملاء، وتقديم المساعدة الفنية، ومعالجة المشكلات المحتملة المتعلقة بالجودة. ونُطبّق التدابير المناسبة لتحسين جودة المنتج وخدمة العملاء من خلال جمع آراء العملاء وتحليلها.

وضعت الشركة عملية السيطرة على الجودة التي تضمن بشكل صارم أن المنتجات تتوافق مع المعايير. نحن نختار موردين ذوي جودة عالية لضمان قابلية التتبع والسيطرة على جودة سلسلة التوريد، والتي تمتد من المواد الخام إلى المنتجات النهائية. لقد حصلنا على شهادات ISO9001 وSGS، وهي مطابقة لمعايير صناعة ألواح السبائك النيكلية ومعايير الصناعة. نقوم بإنشاء استراتيجيات إدارة الجودة وإجراء فحوصات واختبارات الجودة، بالإضافة إلى تسجيل عملية الإنتاج وفقًا لمواصفات الصناعات المعدنية النادرة وغير الحديدية.

لوحة سبيكة النيكل المتطابقة مع TMC METAL سبائك النيكل لها نطاق واسع من التطبيقات في مختلف الصناعات. تُستخدم عادةً في معالجة الكيميائيات، النفط والغاز، الفضاء الجوي، والصناعات الطبية. يمكن استخدامها لتصنيع和支持 المبادلات الحرارية، الأوعية تحت الضغط، والمعدات الأخرى التي تتطلب قوة ومتانة عالية.

لوحة سبيكة النيكل من TMC METAL يمكن قصها، حفرها، ولحامها مثل أي لوحة معدنية أخرى. ومع ذلك، يُوصى باستخدام معدات وأدوات احترافية لتجنب أي ضرر على خصائص اللوحة.

لوحة سبيكة النيكل مثل TMC METAL الكروم والنيكل يقدم موردو وصانعو ألواح سبائك النيكل خدمات متنوعة لعملائهم. يقدمون إرشادات حول اختيار السبائك، يقومون بتخصيص الألواح وفقًا للاحتياجات المحددة، ويوفرون الدعم الفني لضمان التركيب والاستخدام الصحيحين لمنتجاتهم.