Copper-nickel alloys are special kinds of material produced by mixing copper and nickel together. Due to their unique properties, these alloys are highly utilized in diverse sectors. You are a TMC METAL expert on copper-nickel alloys and also manufacture essential goods. Let’s find out more about these alloys and why they are so useful.

Copper-Nickel Alloys: What do you know?

Copper-nickel alloys is an alloy consisting of copper and nickel, having other metals as well. They are known to be tough and long wearing alloys. They got good resistance to rust, even if they stay long in air or in water. Copper-nickel alloys have good electrical and thermal conductivity, which makes them suitable for a variety of applications.

Properties of Copper-Nickel Alloys

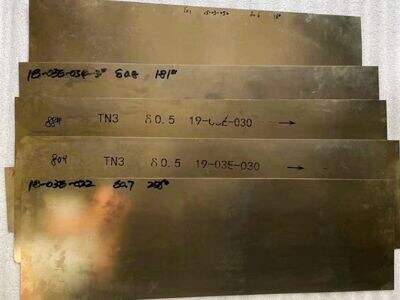

Copper-nickel alloys have a range of useful properties that make them suitable for a wide range of applications. They are tough and can take a lot of abuse without breaking. These alloys are also easy to shape. Copper-nickel alloy plate also has a shiny silver color that is aesthetically pleasing for decorative objects.

Specific Applications of Copper-Nickel Alloys

Copper-nickel alloys are widely used in several sectors due to their unique properties. One of the most common uses is for making coins. Copper-nickel alloy are used to produce coins in many countries due to their strength and wear resistance. Because they are good conductors of electricity, these alloys are also used to produce electrical components such as wires and connectors. And copper-nickel alloys are employed in marine components because they resist corrosion from salt water.

Benefits of Copper-Nickel Alloys

Copper-nickel alloys would certainly be appropriate and advantageous to use in a multitude of applications. They have the added advantage of rust resistance. This ensures that products made from copper-nickel alloys have a long service life without damage. Another benefit is that they are good conductors of both electricity and heat, making them valuable in electrical and industrial applications. The copper-nickel alloys are also not difficult to work with and can be formed into different shapes.

Process used to remove burrs from conducting sleeve (copper-nickel) The article 16mar Copper-nickel alloy metals: Properties, Fabrication and Application Never miss a great news story.

Some tips to ensure best results when working with copper-nickel alloys. First, make sure to wear protective gear, such as gloves and goggles, when working with these alloys, as they can be sharp and hot. Second, make sure you use the proper tools for cutting, bending, or forming the copper-nickel alloys to prevent accidents. Finally, always clean tools and store them properly to prevent alloy contamination.