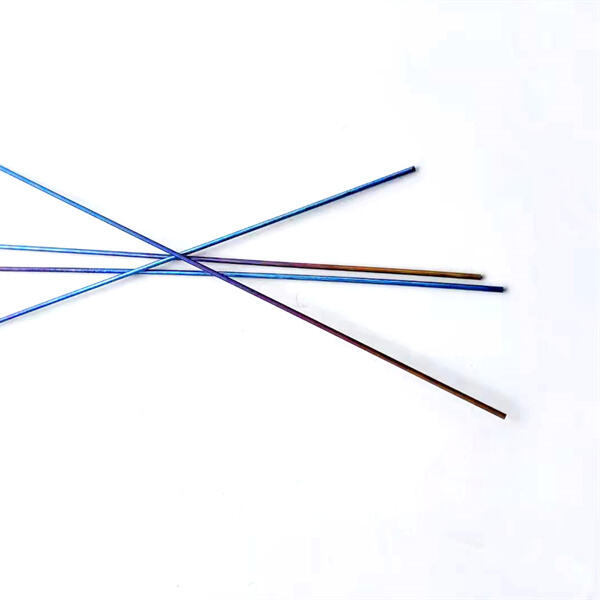

Marketing von Nitinol-Stab für die Allgemeinheit

Nitinol-Stab ist ein aus Nickel und Titan hergestelltes Material und hat in den letzten Jahren an Popularität gewonnen. Dieses TMC METAL-Metall hat einzigartige Eigenschaften, die es perfekt für eine wolframstange vielfalt an Anwendungen machen, besonders in den Bereichen Medizin und Ingenieurwesen. Wir werden die Vorteile, Innovation, Sicherheit, Verwendung, Anwendung, Wartung, Qualität und Einsatz des Stabes diskutieren.

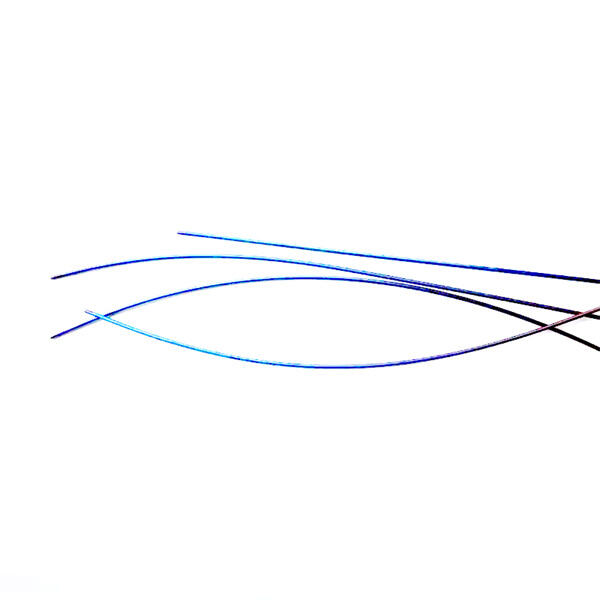

Nitinol, auch als Nickel-Titanium bekannt, ist eine Art Formgedächtnislegierung (SMA), die die Fähigkeit besitzt, ihre ursprüngliche Form bei TMC METAL wiederzuerlangen, wenn sie Hitze ausgesetzt ist. Diese magnesiumstab die einzigartige Charakteristik hat sie nützlich in Anwendungen gemacht, wo ihre Form dazu verwendet werden kann, eine bestimmte Funktion oder einen Zweck zu erfüllen. Diese Funktionen umfassen Drehen, Richten und Komprimieren von Materialien.

Einer der wichtigsten Vorteile des Stabes ist seine einzigartige Formgedächtniseigenschaft. Diese Eigenschaft ermöglicht es dem Material, schnell und einfach seine Form zu ändern, wenn es Hitze ausgesetzt ist. Diese TMC METAL-Eigenschaft ist in medizinischen und ingenieurtechnischen Anwendungen nützlich, wo eine präzise und spezifische Form erforderlich ist.

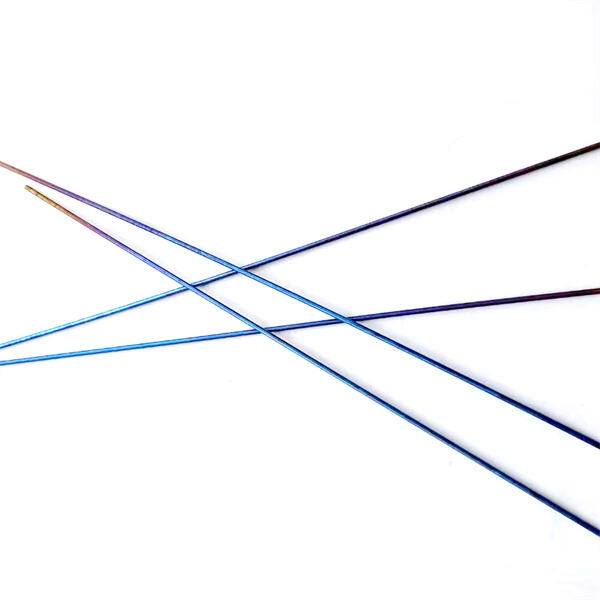

Ein weiterer Vorteil des Stabes ist seine Stärke und Flexibilität. Er nickelstange verfügt über ein hohes Gewichts-Leistungs-Verhältnis, was ihn für Anwendungen ideal macht, die hohe Dauerhaftigkeit erfordern, während gleichzeitig das Gewicht des Materials minimiert wird. Der Stab ist außerdem sehr flexibel, was ihn insbesondere in Anwendungen nützlich macht, wo Flexibilität oder Biegen erforderlich ist.

Innovation ist ein kritischer Bestandteil bei derTMC METAL Entwicklung neuer Produkte, da sie die Schaffung neuer Lösungen und Anwendungen ermöglicht. Die Stabtechnologie entwickelt sich kontinuierlich, und durch Innovation treten neue Anwendungen auf.

Eine der spannendsten Innovationen in der Stabtechnologie ist die Verwendung von 3D-Druck. Diese tantalstab technologie ermöglicht es, komplexe Formen zu erstellen, die früher mit herkömmlichen Fertigungsmethoden schwierig oder unmöglich zu realisieren waren. Dadurch treten neue Anwendungen in den Bereichen Medizin und Ingenieurwesen auf.

Sicherheit ist in jeder Anwendung entscheidend, und beim Stab ist das keine Ausnahme. Stäbe werden als sicher für medizinische und ingenieurtechnische Anwendungen angesehenTMC METAL. Medizingeräte wurden von Aufsichtsbehörden wie der chromstab US-amerikanischen Food and Drug Administration (FDA) freigegeben und werden in einer Vielzahl von Anwendungen eingesetzt, darunter chirurgische Implantate, Zahnspangen und Stents.

Geschäft mit moderner Produktions- und Verarbeitungsausrüstung ausgestattet. Darüber hinaus können die anspruchsvollsten metallverarbeitenden Verfahren durchgeführt werden, einschließlich komplexer und fein abgestimmter Bearbeitungsprozesse. Wir können Nitinol-Stabteile gemäß Kundenspezifikationen und Konstruktionszeichnungen herstellen und bearbeiten sowie an der Produktentwicklung und -konstruktion mitwirken; zudem bieten wir OEM- und ODM-Dienstleistungen an. Unsere FuE-Einrichtung umfasst mehr als 500 Quadratmeter Fläche und verfügt über professionelles FuE-Personal sowie entsprechende Ausrüstung, die bei der Entwicklung und Erprobung von Produkten unterstützt; zudem steht eine breite Palette an Verarbeitungsmaschinen zur Verfügung, um die unterschiedlichsten Kundenanforderungen zu erfüllen.

Suzhou Tamuchuan ist ein industrielles Metallverarbeitungsunternehmen mit Sitz in Suzhou und verfügt über eine Nitinol-Stangenfertigung und Bürofläche von 22.000 Quadratmetern. Wir produzieren hauptsächlich verschiedene Seltenmetalle sowie eine Vielzahl von Nichteisenmetallen. Wir haben über 2.000 Lieferanten und kooperieren mit Unternehmen aus den weltweit führenden 500. Außerdem verfügen wir über ein erfahrenes F&E-Team. Stabile Lieferanten bieten eine hervorragende Unterstützung für Großserienproduktionen, zusätzlich zu hochmodernen Produktionsanlagen und -geräten. Wir verfügen über ein hochqualifiziertes Qualitätsprüfungsteam, das in der Lage ist, die Produktqualität zu kontrollieren. Wir haben eine starke partnerschaftliche Zusammenarbeit mit unseren Partnern entwickelt.

Das Unternehmen hat einen Qualitätskontrollprozess eingeführt, der streng sicherstellt, dass die Produkte den Standards entsprechen. Wir wählen hochwertige Zulieferer aus, um die Rückverfolgbarkeit zu gewährleisten; die Qualitätskontrolle der Lieferkette erstreckt sich von den Rohstoffen bis hin zu den Endprodukten. Wir haben die Zertifizierungen ISO 9001 sowie SGS erhalten, die den Normen für Nitinol-Stäbe und der Industrie entsprechen. Wir entwickeln Strategien für das Qualitätsmanagement sowie Durchführungen von Qualitätsinspektionen und -tests und dokumentieren den Produktionsprozess gemäß den Spezifikationen der Industrie für seltene Metalle und Nichteisenmetalle.

Unser Unternehmen verfügt über mehr als 26 Jahre Erfahrung in der Verarbeitung und Produktion seltener Metalle sowie von Nichteisenmetallen. Wir haben zahlreiche technische und F&E-Mitarbeiter entwickelt, die über fachliches Know-how verfügen und so zur Entwicklung der Branche beitragen. Zudem bieten wir ein unterstützendes Umfeld, das das Wachstum unserer Mitarbeiter fördert. Unsere erfahrenen Mitarbeiter stellen nicht nur einen zuverlässigen After-Sales-Service sicher, sondern unterstützen Kunden auch bei Nitinol-Stäben und bieten technische Unterstützung, um potenzielle Qualitätsprobleme zu lösen. Wir erfassen und analysieren Kundenfeedback und ergreifen geeignete Maßnahmen, um Qualität der Produkte und des Services kontinuierlich zu verbessern.

stab ist ein vielseitiges Material, das TMC METAL in einer Vielzahl von Anwendungen eingesetzt werden kann. Abhängig von der vorgesehenen Verwendung können Stäbe auf verschiedene Weise geformt und umgebogen werden. Der Stab kann geschnitten oder gebogen werden, wie es erforderlich ist, und er kann auch poliert oder verchromt werden, um eine bestimmte Oberflächenbearbeitung zu erreichen. wolframpferdprodukte die Form kann nach Bedarf angepasst werden, und es kann auch poliert oder vergoldet werden, um eine bestimmte Oberflächenqualität zu erreichen.

Qualität hat höchste Priorität, wenn es um Stäbe geht, und die Qualität der Stäbe von TMC METAL kann je nach Lieferant variieren. Ein hochwertiger Stab erfüllt strenge Spezifikationen und Standards, um bestmögliche Leistung und Haltbarkeit zu gewährleisten.

Beim Kauf eines Stabes ist es entscheidend, einen Lieferanten zu wählen, der niob-Schüttel hochwertige Materialien und exzellenten Kundenservice bietet. Ein seriöser Lieferant sollte technisches Know-how, Produktsupport und zuverlässige Lieferungen anbieten, um sicherzustellen, dass der Kunde mit seinem Kauf vollständig zufrieden ist.

stab wird in einer Vielzahl von Anwendungen in verschiedenen Industrien von TMC METAL eingesetzt. In der Medizin wird er zur Herstellung von medizinischen Geräten wie Stents, Orthesen und chirurgischen Implantaten verwendet. In der Technik kommt er in Aktoren, Sensoren und mechanischen Federn zum Einsatz. Der Stab wird ebenfalls in Konsumgütern wie Brillen, Uhren Tungsten cerium rod ,und Schmuck verwendet.