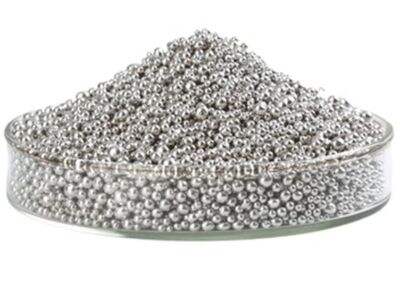

インジウムは頑丈な真空シールの開発においてプロセス上重要な金属であり、真空シール材として使用される低融点合金においてインジウムが重要な役割を果たしているため、その存在を理解しておく必要があります。

信頼性の高い真空シールにおけるインジウムの重要性

インジウムは真空シールが堅牢で安全であることを保証するために不可欠です。インジウムは二つの表面同士を密着させて真空シールを形成するために用いられます。この金属は特徴的ですが、空気や他の物質が透過しにくい非常にタイトなシールを形成することができます。信頼性のある真空シールを作成するにはインジウムまたは類似の金属が必要です。

セラミック系低融点封止材料におけるインジウムの溶解性と高温域での気密性への影響:インジウムが低融点合金の密封性能を最適化する役割

インジウムはさまざまな金属と合金化されることが多く、低融点の合金を生成し、効率的にシールします。これらの合金はインジウムの融点よりも低い温度で溶融するため、素材を過熱することなく真空シールを可能にします。このような合金にインジウムが含まれることにより、シール作業において最大限の性能を発揮することができます。

真空シールに最適なインジウムの特徴を探る

インジウムには真空シールに理想的な金属特性がいくつかあります。非常に柔らかく変形性が高いので、コーティングされた表面の形状に容易に形成できます。これにより、空気やその他の物質が漏れるのを防ぐ完全な気密シールを簡単に得ることができます。 インジウム金属 また腐食にも強く、真空シールはかなり長い期間維持されます。

真空状態を維持し、ガスや液体の漏れを防ぐインジウムの役割

インジウムが真空シールにおいて果たす重要な役割の一つは、不透過性です。二つの表面がインジウムによって接合されると インジウム , 封止が形成され、封入された環境への空気や他の物質の出入りが防がれます。これは真空状態において特に重要であり、漏れが全体的なシール性能に悪影響を及ぼす可能性があります。インジウムは金属としてこの重要な役割に適した特徴を持っています。

高品質で長寿命な真空シールに使用される主成分としてインジウムが選ばれる理由

高品質で長寿命な真空シールにはインジウムなしでは製造が不可能です。密着性、低融点、耐食性といった特性が組み合わさり、インジウムはこれらのシールにおいて中心的な素材となっています。強度、信頼性、耐久性といった言葉が連想されますが、これらすべてが インジウム , なしにはこのようなシールを製造することが極めて困難になるということでもあります。TMC METALは超高真空シール技術におけるインジウムの重要性を理解し、信頼性の高いインジウムベース製品の提供に注力しています。