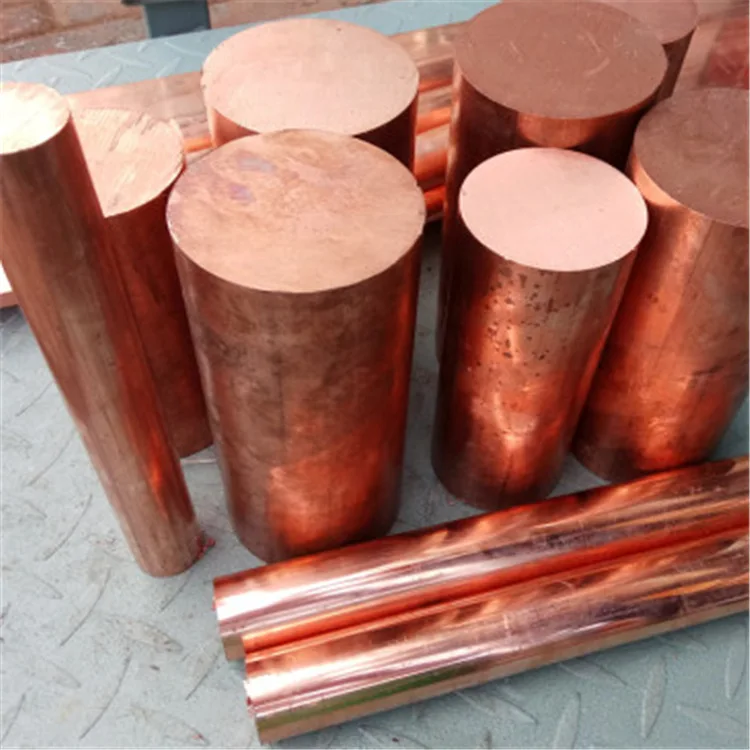

Зэсний хайлшууд нь цахилгаан техникт маш чухал үүрэгтэй металлууд юм. Тэдгээрийг олон төрлийн цахилгаан багаж, аппаратуудад ашигладаг. Зэс бол гайхалтай цахилгаан дамжуулагч юм, өөрөөр хэлбэл цахилгааныг маш хялбархан дамжуулдаг. Гэсэн хэдий ч зарим тохиолдолд цэвэр зэс хангалтгүй байдаг. Бид зэсийг өөр хэд хэдэн металлуудтай хольж зэсний хайлш үйлдвэрлэдэг. Эдгээр хайлшуудад тусгай шинж чанарууд байж болох бөгөөд жишээ нь илүү хатуу эсвэл износод тэсвэртэй байх зэрэг нэмэлт давуу талуудыг олгоно. Иймээс ихэнх инженер, үйлдвэрлэгчид, жишээ нь TMC METAL зэрэг компаниуд өөрийн төслүүдэд зэсний хайлшуудыг илүүд үздэг. Цахилгаан хэсгүүдэд ухаалаг сонголт болох нь тэдгээрийн дамжуулалт, хүч, найдвартай байдлын хувьд хамгийн тохиромжтой байдаг.

Цахилгаан техникт яагаад зэсний хайлшуудыг ашигладаг вэ?

Төмрийн эзэг цахилгаан бүрэлдэхүүнд оролцож байгаа нь тэдгээрийн ач холбогдол байдаг тул шалтгаантай. Тэд сайн дамжуулагчид юм, тэр хэлсэн. Зэсний хайлш доторх цахилгааны урсгал их хэмжээний энерги алдахгүй бөгөөд зүйлсийн үр ашигтай ажиллагааг хангахад чухал ач холбогдолтой байдаг. Жишээ нь, үйлдвэрлэл болон гэр бүлд өргөн хэрэглэдэг зэсний хайлш цахилгаан утас. Эдгээр нь гэрэл, машин, компьютерийг зам явуулах явцад энергийг алдалгүй ажиллуулдаг. Энэ дамжуулалт нь энгийн зүйлсийн хувьд л биш харин цахилгааны сүлжээ шиг нарийн системүүдийн хувьд чухал юм. Олон тооны зэсний хайлш хатуу бөгөөд исэлдэхээс хамгаалагч чанартай байдаг. Иймд тэд маш хэцүү нөхцөлд ч удаан хугацаагаар ажиллах чадвартай гэсэн үг юм. Зарим газарт зэсний хайлш чийг, химийн бодисын хор хөнөөлд илүү тэсвэртэй байдаг. Энэхүү урт нас бие даах чадвар нь засвар, солилтоос сэргийлэхэд тусалж, тэдгээрийн зардлыг бууруулдаг. Гурав, зарим зэсний хайлш өндөр температурт тэсвэртэй байх зэрэг тусгай чанаруудтайгаар зохион бүтээгддэг. Жишээ нь, зарим хайлш цахилгаан хөдөлгүүрт ашиглагдаж болох ба эдгээр нь ажиллах үед дулаан үүсгэдэг. Энэхүү дулааны эсэргүүцэл нь тоног төхөөрөмжийн гэмтлийг сэргийлдэг бөгөөд аюулгүй байдал, найдвартай ажиллагаа ч мөн хамаарна. Зэсний хайлш руу хандвал инженер нь загварынхаа үр ашиг, найдвартай байдлыг итгэлтэй хангаж чадна. Эцэст нь, зэсний хайлш янз бүрийн хэлбэр, хэмжээтэй байдаг тул олон төрлийн хэрэглээнд хялбархан тохируулж болно. Энэ нь гар утасны жижиг холбоос эсвэл үйлдвэрийн том кабель байхад ч зэсний хайлш шаардлагыг хангаж чадна. Энэхүү олон талт чанар нь TMC METAL-ийг цахилгаан бүрэлдэхүүний шаардлагыг бүрэн хангахын тулд хамгийн сайн зэсний хольцуудад зориулахад нөлөөлж байна.

Хамгийн өндөр чанартай нийлүүлэгчдээс зэвэрдэггүй хайлшийг бөөний болон худалдан авах

Хэрэв та цахилгаан инженерчлэлийн салбарт ажилладаг бол өндөр чанартай зэсний хайлшны нийлүүлэгчидтэй холбогдох нь чухал юм. Интернетэд шалгаарай – энэ нь хайх хамгийн сайн газар юм. Нийлүүлэгчид бараагаа үзүүлдэг олон вебсайт байдаг. Хэрэв та ийм үйлчилгээ хайж байгаа бол тэдгээрийн нэр хүндийг заавал шалгана уу. Бусад хэрэглэгчдийн үлдээсэн санал, хүлээж баталгаажуулалтыг анхаарч үзнэ үү. Энэ нь найдвартай нийлүүлэгчийг олох сайн арга юм. Том захидал өгөхийн өмнө туршилтын дээж авч болох эсэхийг мөн шалгахыг хүсэж болно. Ийм аргаар та өөрөө зэсний хайлшны материалуудыг шууд үзэж болно. Мэргэжлийн үзэсгэлэн, ажлын арга хэмжээнүүд нь нийлүүлэгчидтэй хувийн түвшинд уулзахад бас маш тохиромжтой боломжийг олгоно. Та тэдэнтэй өөрийн шаардлагын талаар ярилцах, мөн бүтээгдэхүүнүүдийг нь шууд үзэх боломжтой. Үзэсгэлэн дээр та өөрийн тодорхой шаардлагад нийцсэн нэмэлт тусгай хайлшнуудыг нийлүүлж чадах өөр нийлүүлэгчидтэй танилцах боломжтой. Мөн орон нутгийн металл боловсруулагчидтай холбоо барихыг авч үзнэ үү. Агуулаш руу очих нь зөвхөн материалуудыг үзэх зам биш, харин асуултаа шууд асууж болох боломжийг ч олгоно. Мөн орон нутгийн нийлүүлэгчидтэй ажиллах нь зарим тохиолдолд илүү хурдан хүргэлтийн хугацааг хангаж чадна. TMC METAL зэрэг компаниуд нь бүтээгдэхүүний өндөр чанар, үйлчилгээ, дэмжлэгийн хослолыг санал болгодог бөгөөд энэ нь худалдан авах явцыг илүү хялбар болгоход тусалж болзошгүй. Тэд янз бүрийн цахилгаан инженерчлэлийн шаардлагад нийцсэн олон төрлийн зэсний хайлшнуудыг нийлүүлдэг. Мөн таны нийлүүлэгчидтэй сайн харилцаа хөгжүүлэх нь сайн байх болно. Хэрэв тэд та юу хайж байгааг мэдэж байвал тэд илүү сайн үйлчилгээ үзүүлж, жижиглэнгийн худалдааны хямдрал ч гэсэн өгч болзошгүй. Хамгийн сайн нийлүүлэгчийг олохын тулд цаг гаргахад та өөрийн төслүүдэд хамгийн сайн зэсний хайлшуудыг ашиглах замд орж, энэ нь цахилгаан инженерчлэлийн хэрэглээнд илүү сайн үр дүн гарахыг хангана.

Цахилгаан хэрэглээндээ хамгийн тохиромжтой зэсний хайлш яаж сонгох вэ

Хамгийн сайн зэсийг сонгох хайлуур цахилгаан төслүүдэдээ зориулан зэс сонгох нь маш чухал шийдвэр юм. Зэс байгалийнх нь төлөвт зөөлөн метал бөгөөд ган эсвэл төмөр шиг хялбархан хайлж, хэлбэржүүлдэггүй. Зэсний хайлш нь өөр өөр металлтай холилдон тодорхой шинж чанарыг сайжруулдаг. Эхлээд та хайлшаас юу хийхийг хүсэж байгааг тодорхойлох хэрэгтэй. Та утас, холбох хэрэгсэл эсвэл бусад юу нэгнийг үйлдвэрлэж байна уу? Хайлш бүр өөрийн давуу болон дутагдалтай талтай. Жишээ нь, цахилгааныг сайн дамжуулах зүйл хэрэгтэй бол та цахилгаан дамжуулах чанар сайтай зэсний хайлш сонгох боломжтой. Дамжуулалт гэдэг нь материал цахилгааныг хэр их дамжуулах чадвартайг илэрхийлнэ. TMC METAL нь цахилгаан инженерийн тодорхой хэрэглээний салбарт зориулан сайжруулсан олон төрлийн зэсний хайлшныг нийлүүлдэг.

Эцэст нь та бий болгох орчны агаар манайг төсөөлөн бодно уу. Зарим хайлш нь тодорхой нөхцөлд илүү сайн ажилладаг. Хэрэв та төслөө гадаа ашиглах бол цахилгаан эсвэл агаартай урвалд орж дэгдэхгүй, зэврэхгүй цагаан алтны хайлш сонгоно уу. Металл ус эсвэл агаартай урвалд орж зэврэх, будагдах үзэгдлийг зэврэлт гэж нэрлэдэг. Таны төслийн зайг илүү сайн болгохын тулд TMC METAL-ийн цагаан алтан хайлшийг яагаад сонгох вэ гэвэл TMC METAL нь таны төслийн хүрээнд ийм нөхцөл байдлыг үүсэхээс сэргийлэх зориулалтаар онцгой хөгжүүлсэн цагаан алтан хайлштай.

Нөгөө нэгэн хүчин зүйл бол хайлшруу үзүүлэх стрессын хэмжээ юм. Хэрэв таны төсөл их стресс эсвэл хөдөлгөөнд оролцож байгаа бол таньд хүчтэй хайлш хэрэгтэй болно. Зарим цагаан алтны хайлш хүчтэй байхаар зориулагдсан бөгөөд цаг агаарын илүү их нөхцөлд тэсвэртэй байдаг. Таны төслийн хувьд аль хайлш хамгийн тохиромжтойг мэдэхгүй байгаа тохиолдолд тусламж авахад хичээгүйгээр хандана уу. TMC METAL нь танд зөв сонголт хийхэд туслах мэргэжлийн ажилтнуудтай. Эцэст нь үнэийг бодолцоно уу. Зарим цагаан алтны хайлш үнэтэй байдаг тул чанар, үнийн хооронд тэнцвэрийг олох нь сайн байдаг. TMC METAL-ийн өргөн спектртэй бүтээгдэхүүнүүд нь таны төсөвт тохирч, сайн үзүүлэлттэй байх боломжийг олгоно.

Цахилгаан инженерийн салбарт цагаан алтны хайлшууд ямар асуудлуудтай байдаг вэ?

Цахилгаан бүрэлдэхүүнд харь олборыг ашиглах үед гардаг ердийн асуудлууд. Хэрэв та цахилгаан бүрэлдэхүүнд харь олборыг ашиглаж байгаа бол дараах асуудлууд тантай тохиолдох магадлалтай. Асуудлын нэг бол исэлдэлт юм. Утасны харь агаартай урвалд орж, дамжуулалтыг муутгаж болох давхаргыг үүсгэдэг. Энэ давхарга нь холболтуудыг сулруулах, гүйдлийн дамжуулалтыг бууруулах боломжтой. Исэлдэлтийг саатуулахын тулд харь олборыг цэвэр байлгах нь чухал. Мөн харь олборыг сайн байдлын түвшинд хадгалах зарим зассан залгаж засах зөвлөмж, аргачлал байдаг. TMC METAL нь харь олборын материалуудаа исэлдэлтээс хамгаалах зориулалттай зөвлөгөө, бүтээгдэхүүнүүдийг санал болгодог.

Нөгөө асуудал бол ядарч түлшрэх юм. Ядарч түлшрэх үзэгдэл нь металл олон дахин нугалагдах эсвэл ихэсэх үед үүсдэг. Энэ нь цаг хугацааны дараа хайлшийн трещин эсвэл хугарал үүсэхэд хүргэж болзошгүй. Ядарч түлшрэлийг хамгийн бага байлгахын тулд ажлын зориулалтад тохирсон зэсний хайлаасыг сонгох нь чухал. Зарим хайлш илүү уян зунгаар, зарим нь илүү бат бөх байдлаар гарган бэлтгэгддэг. TMC METAL нь янз бүрийн зэсний хайлшуудыг нийлүүлж, өөр өөр түвшний элэгдэл, шигшилтийн шаардлагад нийцүүлэн ажилладаг. Материал сонгохдоо таны төслийн хэр их идэвхитэй байх боломжтойг мөн анхаарах нь зүйтэй.

Гэхдээ зэвэрдэг цайрын хайлштай нийцэх асуудал гарч болзошгүй юм. Гэхдээ энэ нь бүгд хоорондоо сайн ажиллана гэсэн үг биш юм. Хоёр ялгаатай металлыг нэгтгэх үед зарим уул уурхайн шинжлэх ухааны мэргэжилтнүүд гальваник корроз, цахилгаан энерги үүсэх зэрэг боломжит асуудлыг сааруулахыг оролддог. Янз бүрийн материалын хоорондын хамаарлыг мэдэх нь маш чухал юм. TMC METAL нь цахилгаан бүтээгдэхүүний төслүүдэдээ хамгийн тохиромжтой шийдлийг гаргахад туслах мэдлэг чадвар, нөөцийг танд санал болгодог.

Эцэст нь, зарим цайрын хайлш нөгөөсөө илүү үнэтэй байдаг. Та чанартай материал ашиглахыг хүсвэл ч, мөн зардалд хяналт тавих шаардлагатай. TMC METAL нь чанарыг хэтрүүлэлгүйгээр таны төсөвт тохирсон сонголтуудыг санал болгодог.

Цайрын хайлшуудыг ашиглан цахилгаан шийдэл хэрэгжүүлэх

Зэсний хайлш нь цахилгаан системийг тэвчээртэй болгох чухал үүрэг гүйцэтгэдэг. Тэвчээрт байдал гэдэг нь бид өөрсдийн хэрэгцээгээ хангаж, гаригийг задлахгүй байх ёстой гэсэн үг юм. Зэсний хайлш нь дахин боловсруулах чадвар сайтай байдлаараа энэ боломжийг хэдий хэмжээгээр нэгтгэвэл энэ нь боломжтой. Төмөр чанарыг алдахгүйгээр олон дахин дахин боловсруулж болдог ховор бодисуудын нэг юм. Таны төслүүдэд зэсний металл ашиглах нь хаягдлыг багасгаж, нөөцийг хэмнэхэд тусалдаг эргэлтийн эхлэлд оролцох болно. TMC MEATAL нь дахин боловсруулахад хялбар бөгөөд орчин үеийн экологийн шаардлагад нийцсэн тэвчээртэй төслүүдэд ашиглах идэал материал болох чанартай зэсний суурь хайлшуудыг үйлдвэрлэдэг.

Зэсний хайлшуудыг ашигласнаар эрчим хүчний үр ашигтай шийдэл хэрэгжих бөгөөд уламжлалт хөгжилд хүрэх боломжийг бүрдүүлдэг. Зэс агуулсан хайлшнууд нь ихэвчлэн гайхалтай цахилгаан дамжуулах чадвартай байдаг. Энэ нь утас, холболтуудын дамжуулалтаар цахилгааныг дамжуулах үед эрчим хүчний алдагдал бага байдаг гэсэн үг юм. Бид эдгээр үр ашигтай материалыг ашиглах замаар эрчим хүчний хэмнэлт хийдэг бөгөөд энэ нь орчин үеийн орчныг хамгаалахад сайн нөлөө үзүүлдэг. Бид TMC METAL-д цахилгаан дамжуулах чадвар сайтай, дэвшилтэт зэсний хайлшнуудыг санал болгож байгаа бөгөөд инженерүүд эдгээр материалыг ашиглан эрчим хүчийг илүү үр ашигтайгаар ашигладаг системүүдийг бүтээх боломжтой.

Зэсний хайлшууд нь солар панел, цахилгаан ороомог зэрэг сэргээгдэх шинэ эрчим хүчний салбарт өргөн ашиглагддаг. Бид цэвэр эрчим хүчний эх үүсвэр лүү шилжих тул эдгээр нь маш чухал байх болно. Эдгээр хэрэглээнүүд зэсний хайлш ашиглан өөрсдийн үйл ажиллагаа болон үйлдвэрлэлийн насныг уртасгадаг. Байгалийн нөөцийг хэт ашиглахаар дэлхийг задлахгүйн тулд TMC METAL нь цэнхэр технологийн зэсний материалыг ашиглахыг дэмждэг.

Эцэст нь, зэсний хайлш ашигласнаар илүү урт хугацаагаар үйлчилдэг бүтээгдэхүүн гаргаж авах боломжтой гэдгийг тэмдэглэх хэрэгтэй. Бүтээгдэхүүн өчүүхэн үнэтэй болгох тусам түүний амьдралын хугацаа уртсаж, орон тооны нөөцийг дахин орлуулах шаардлага багасна. Энэ бол тэгш хандлагын нэг хэсэг юм. Инженерүүд найдвартай, тэгш хандлагатай цахилгаан шийдлүүдийг бүтээх боломжтой болгохын тулд TMC METAL хүчирхэг, бат бөх зэсний хайлш дээр анхаарч ажилладаг. Зохистой материал ашиглан бид бүгд дэлхийг ирээдүй үеийнхэнд хадгалан хүргэхэд хувь нэмрээ оруулах боломжтой.

Гарчиг

- Цахилгаан техникт яагаад зэсний хайлшуудыг ашигладаг вэ?

- Хамгийн өндөр чанартай нийлүүлэгчдээс зэвэрдэггүй хайлшийг бөөний болон худалдан авах

- Цахилгаан хэрэглээндээ хамгийн тохиромжтой зэсний хайлш яаж сонгох вэ

- Цахилгаан инженерийн салбарт цагаан алтны хайлшууд ямар асуудлуудтай байдаг вэ?

- Цайрын хайлшуудыг ашиглан цахилгаан шийдэл хэрэгжүүлэх