TMC METAL knows just how much the right alloy can impact an item's longevity and performance. When we talk about alloy compositions, it is the various metal elements that are used in conjunction with one another to form the alloy. Different combinations can help a product resist rust, tolerate heat better or remain strong under pressure. For instance, if you mix aluminum and copper together, you get a metal strong but lightweight. That is critical on, for example, airplanes where every ounce matters. Knowing our alloy compositions is what ensures that our products are ready for whatever you need them to be

What are the critical ingredients in improving the durability of products is

Different metals have unique properties. Meld them in a mash-up, and we can make something better still. TMC METAL is designed to utilization of the right things in all combos. For example, stainless steel is produced by combining iron with chromium and nickel. This solution aids in keeping away rust and is such a necessary item for kitchen tools and appliances. Another is bronze, which comprises copper and tin. Bronze is harder than plain copper and holds up better outside. And that is why you will see us using it, for example, in sculptures and coins Sometimes we add trace amounts of other metals, such as phosphorus or manganese, to make it stronger or more flexible. We can see this in certain types of steel, the more carbon you add to it, the stronger it will become. We also examine how these alloys behave in different situations

Alloy Composition Variation and Performance in Wholesale Products

TMC METAL are designed for guns that have load-out requirements. For instance, in cars, car parts must be strong but not too heavy. With aluminum alloys, we can develop parts that are easy for automakers to work with and that contribute to better fuel economy This is significant, because lighter cars drink less gas. On the other hand, for some products tools come to mind very tough is necessary. That’s where high-carbon steel comes into play. This alloy is harder and can withstand a good deal of wear and tear, which makes it ideal for hand tools. We also consider how these products will be used. If something’s going to be outside, it better be corrosion resistant. So, we could use alloys with a bit more chromium or nickel to combat that. Every option for alloying composition will impact the product’s real world performance. That’s why we listen intently to what our customers want and the types of marketplaces they participate in. By being aware these aspects TMC METAL can provide excellent service to business and their clients

How to Source High-Quality Alloys for Better Product Performance

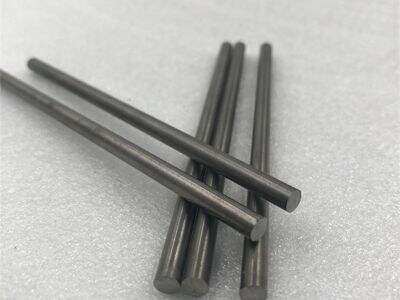

But, where can you actually find alloys of a high caliber. Alloys are unique materials produced by combining different metals. That is why they go into all sorts of products, from planes to bicycles because they can make things stronger or lighter or more resistant to rust. A great source of good quality alloys are manufacturers of these such as TMC METAL. Those companies all produce alloys to exacting standards. They have skilled workers and high-end machines to ensure the quality of their products

There are also high-quality alloys at your nearby metal stores if you cannot reach a gunsmith. In such suppliers, a variety of metals and alloys are stocked and available for immediate purchase. There are good questions to be asked about where these metals come from and how they are made. Some suppliers will even offer a sample so you can try out the alloys before purchasing them

Or you can search online shops for alloys. There are many well-known companies that have websites where you can view the various alloys available. When shopping online, people should read reviews and see the company’s ratings before pulling out a credit card. Ensure that the company offers quality products. TMC METAL is a great supplier of good quality alloys, and you can rely on their products for your projects

Lastly, you may also consider attending trade shows and/or industry events to get access to high-quality alloys Quite often these events are the grounds for presenting new materials and technologies. You can meet manufacturers, hear about new products and even see demonstrations of how the alloys work. This is an excellent way to network with professionals in the industry and obtain information that can ensure you are making informed decisions on what alloys to use

Why are Specific Alloy Compositions Better than Others for Specific Applications

Different alloy mixtures are suited for different tasks. The reason is that every metal has its unique properties. For instance, some alloys are very strong while others resist heat or are feather-light. If you’re looking to pair a specific use with an alloy, it’s worth considering what the product will be used for

Strong but light-weighted alloys are, such as those used in aerospace industry and the like where safety is critical for example, also desired. Aviation typically uses lithium batteries because, while they are light, there is potential for greater risk with them. animateWithDuration:0.33 animations: {[self view layoutSubviews];}]; Silver ions can corrode the aluminum alloys in these aircraft when those metals come into contact with moisture from a battery that has released electrolyte or water simply used to fight a fire accompanying a fire involving aviation products On the other hand, very high strength and good durable steel alloys are required in building. These are heavy load bearing and will not wear over time

TMC METAL provides a range of mixtures tailored to certain applications. Their team are aware of what makes a successful composition in every given scenario. This information enables customers to choose the appropriate materials for their application

Another important consideration is how the alloy behaves in the environment. For instance, if an alloy will be near saltwater, it should have the ability to resist corrosion. Stainless steel is convenient for use in the marine field hence it has anti-rust ability. On the other hand, if an alloy is to be exposed to extreme heat then special cooled positions that are heat resistant will be required

Knowledge of the specific requirements of an application allows manufacturers to select the proper alloy. This means the end result will look good and last long. The ideal alloys will lead to safer, stronger and more efficient products

What Are the New Development Trends of Alloy Compositions for Product Performances

The alloy content is changing all the time as technology becomes better. There are new things happening that make products even better. Among the biggest trends is the use of lighter materials. Weight is increasingly becoming a consideration as the industry searches for ways to trim pounds without losing strength. That is particularly crucial in the automotive and aerospace industries, where every ounce is critical

Even lighter and stronger aluminum alloys are under development. These alloys could be used to produce more fuel-efficient vehicles and aero planes. TMC MÀTAL is pioneering this new developments by developing advanced alloys for the problems of today’s industry

Both and bigeye are part of the sustainability trend. A lot of businesses are searching for the means to have their products be environment-friendly. This involves the recycling of materials into alloy mixtures Companies can cut waste and reduce environmental impact by making alloys from recycled metals. At TMC METAL we are passionate about our alloy's purity, quality products and environmental performance

In addition, smart alloys are currently of interest. These are things that can change their properties depending on the environment. For instance, certain alloys tend to get stronger when heat is applied. This makes them suitable for use in engineering and technology applications. There is work being conducted on R2R to investigate the possibilities of these new smart materials and TMC METAL plays an active part in these exciting developments

The trend in alloy composition] to keep pace with the times aims at lighter, more ecological and smarter products By following these trends, businesses can optimise their product offering and consumer requirements. TMC METAL focuses on new alloys that support these trends, to guarantee that their customers will have the best materials in hand

Table of Contents

- What are the critical ingredients in improving the durability of products is

- Alloy Composition Variation and Performance in Wholesale Products

- How to Source High-Quality Alloys for Better Product Performance

- Why are Specific Alloy Compositions Better than Others for Specific Applications

- What Are the New Development Trends of Alloy Compositions for Product Performances