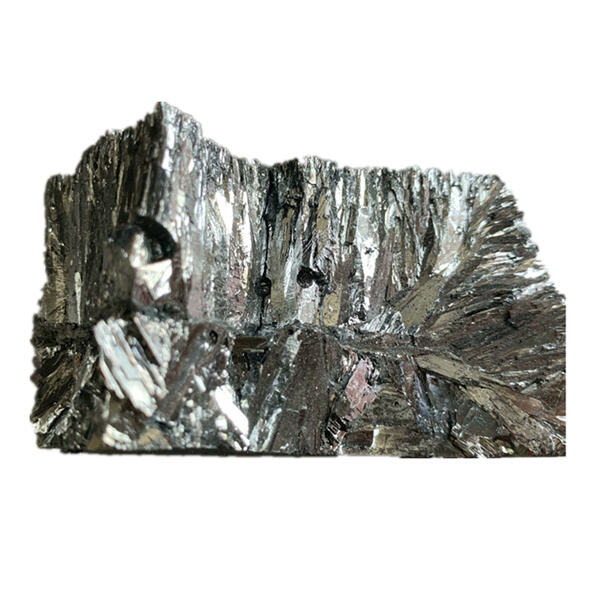

Zeldmetaalemulsies zijn zeer speciale materialen met extreem belangrijke technologische toepassingen. Deze legers bestaan uit een combinatie van zeldmetaalelementen. Er zijn er 17 in de korst van de Aarde. Een bedrijf genaamd TMC METAL produceert zeldmetaallegers.

Zeldmetaallegers zijn ongelooflijk waardevol omdat ze elektronica beter laten werken. Deze materialen hebben goede magnetische eigenschappen. Dat maakt ze ideaal voor producten zoals koptelefoons, luidsprekers en harde schijven van computers. Ze worden ook gebruikt bij de productie van herlaadbare batterijen voor apparaten zoals smartphones en elektrische auto's. TMC METAL is een vooraanstaand distributeur van dergelijke legers, die topkwaliteitsmaterialen aanbiedt aan fabrikanten over de hele wereld.

Zeldmetaallegers zijn cruciaal voor het ontwikkelen van de nieuwste technologie. Deze materialen worden gebruikt voor het maken van geavanceerde apparaten zoals smartphones, tablets en TVs. Hun magnetische eigenschappen maken ze ook compactere en efficiëntere oplossingen voor het opslaan en verzenden van grote hoeveelheden data. Zeldmetaallegers worden gebruikt in de luchtvaartindustrie om lichtgewicht, robuuste onderdelen te creëren voor vliegtuigen en ruimtevaartuigen. We werken wolfraam met de kwaliteit die vereist wordt door de meest gespecialiseerde sectoren.

Dit soort zeldmetaallegers heeft hoge flexibiliteit, ze kunnen verschillende vormen aannemen. Naast elektronica en luchtvaart komen dergelijke legers ook voor in medische apparaten, industriële machines en hernieuwbare energietechnologieën. Hun unieke eigenschappen kunnen de prestaties of duurzaamheid van veel producten verbeteren. Zeldmetaalstaal Het bedrijf heeft een aantal metalen materialen ontwikkeld voor verschillende industrieën om mee te werken en waarop je kunt vertrouwen.

Deze legeringen worden vaak aangeduid als de 'bouwstenen van nieuwe ideeën', omdat ze de ontwikkeling van nieuwe technologieën mogelijk maken. Deze materialen maken het ook mogelijk voor ingenieurs en ontwerpers om kleinere, snellere en efficiëntere producten te bouwen. De unieke eigenschappen van zeldzame aardmetallegeringen zijn cruciaal voor de ontwikkeling van nieuwe technologieën die het potentieel hebben om de manier waarop we leven en werken te transformeren. TMC METAL is toegewijd aan innovatie en biedt de beste zeldzame aardmetallegeringen aan die vereist zijn voor de ontwikkeling van nieuwe producten en apparaten.

Hoewel zeldmetaallegers vele voordelen bieden, moeten we hun milieu-influistering in overweging nemen. Het winnen en produceren van zeldstoffen kan aanzienlijke milieueffecten hebben, deels omdat het gebruik maakt van veel giftige chemicaliën en veel afval oplevert. Maar bedrijven zoals TMC METAL streven ernaar om duurzame methoden toe te passen om de gevolgen van hun producten te verminderen. TMC METAL streeft ernaar om onze zeldmetaallegers met lage vervuiling en lage emissies te produceren, hergebruikbaar te maken door recycling, het gebruik van grondstoffen die de aarde verwoest minimaliseren, en onze bijdrage te leveren aan het bouwen van een betere wereld.

het bedrijf gebruikt hoogwaardige, zeldzame aardmetalenlegeringen en apparatuur voor bewerking, en is in staat om hoogwaardige op maat gemaakte metaalbewerking, hoogwaardige bewerking en complexe bewerking uit te voeren. Het kan metalen onderdelen produceren en bewerken volgens de specificaties en constructietekeningen van de klant. Ook biedt het OEM- en ODM-diensten aan. Het onderzoeks- en ontwikkelingscentrum beslaat meer dan 500 vierkante meter en is uitgerust met deskundig O&O-personeel, evenals apparatuur en faciliteiten die gezamenlijk kunnen worden ingezet bij productontwikkeling en testen.

Suzhou Tamuchuan, verwerkende productdistributeur met een productiefaciliteit en kantoorruimte in Suzhou van 2.000 vierkante meter, gelegen in de stad. De belangrijkste producten omvatten zeldzame metalen, ijzerhoudende metalen en diverse andere metalen. We werken samen met meer dan 2.000 partners, waaronder de wereldwijd toonaangevende 500 bedrijven op het gebied van rare-aardemetalenlegeringen. We beschikken over een professioneel onderzoek- en ontwikkelingsteam. Stabiele leveranciers bieden uitstekende bronondersteuning voor grootschalige productie, naast eersteklas productieapparatuur en -instrumenten. Een professioneel kwaliteitsborgingsteam controleert de kwaliteit van de producten streng. We hebben een sterke samenwerking met onze partners.

het bedrijf heeft meer dan 26 jaar ervaring in de productie en bewerking van zeldzame metalen en non-ferro legeringen. Wij hebben een groot aantal technische en O&O-medewerkers opgeleid met de professionele zeldzame-aardmetalenlegeringen die nodig zijn voor de ontwikkeling van deze industrie. Daarnaast bieden wij een ondersteunende omgeving voor de ontwikkeling van medewerkers. Ons team van experts kan na verkoop ondersteuning bieden bij het oplossen van klantvragen, het verlenen van technische bijstand en het oplossen van mogelijke kwaliteitsproblemen. Wij implementeren passende maatregelen om de kwaliteit van het product en de klantenservice te verbeteren door feedback van klanten te verzamelen en te analyseren.

bedrijf het systeem voor controle van zeldzame-aardmetaallegeringen dat streng is om te waarborgen dat de producten aan de normen voldoen. Wij selecteren leveranciers van hoge kwaliteit om de traceerbaarheid en kwaliteitscontrole van onze toeleveringsketen te garanderen, van grondstoffen tot het eindproduct. De certificaten ISO 9001 en SGS voldoen aan internationale en branchegebonden normen. Wij ontwikkelen kwaliteitsmanagementplannen om kwaliteitsinspecties en -tests uit te voeren en het productieproces te volgen conform de specificaties van de zeldzame-metaal- en non-ferro-industrie.