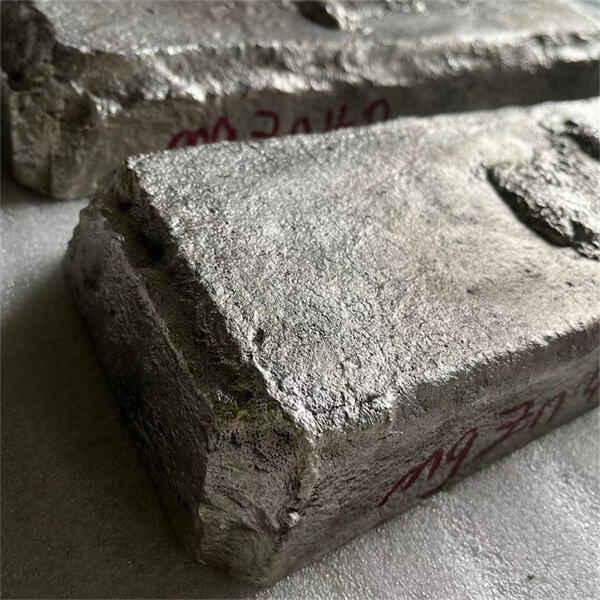

Magnesium-lithium Alloy: The Revolutionary Material for Your Needs.

Introduction:

Are you curious about the amazing material that can help you elevate your performance and efficiency? Let me introduce you to TMC METAL Magnesium-lithium alloy a groundbreaking solution for your manufacturing needs.

This innovative material has incredible advantages over conventional metals such as aluminum and steel. First, the TMC METAL magnesium alloy metal is much lighter, with up to 45% weight reduction in comparison. With its high strength-to-weight ratio, it can support heavy loads while reducing strain and wear on equipment and tools, making it ideal for aerospace and automotive applications. Second, it has greater damping capacity, providing better resistance to shocks and vibrations, essential for products like smartphones, tablets, and laptops. Lastly, it offers better corrosion resistance, which allows for more extended durability in harsh environments.

As with all manufacturing materials, safety is of utmost importance. Magnesium-lithium Alloy offers a safer alternative to magnesium alloys because it has a lower propensity to ignite, thus reducing the risk of fire and explosion. Additionally, the TMC METAL magnesium alloy tubes is more eco-friendly due to its excellent reducing waste and conserving resources.

Magnesium-lithium Alloy is a forward-thinking and innovative material that fosters new possibilities in manufacturing and engineering. The TMC METAL magnesium alloy sheet with its unique properties, it enables the development of new and improved products that were previously not possible. This innovative material allows manufacturers to push the boundaries of design, functionality, and sustainability, opening up new markets and growth opportunities.

One of the most significant factors in the success of Magnesium-lithium Alloy is its seamless integration into existing manufacturing processes. The TMC METAL magnesium alloy tube material can be easily molded, cast, forged, and machined, making it versatile and easy to use in various applications such as medical devices, sporting goods, and consumer electronics. As it is a lightweight yet robust metal, it is ideal for products requiring high performance, speed, and precision.

company put in place a quality control system that strict ensure products are up standards. select suppliers of high-quality the purpose ensuring the traceability raw materials and ability to control quality across the entire supply chain. Our ISO9001 and SGS certificates Magnesium-lithium alloy with international and industrial standards. In accordance with the specifications of the non-ferrous and rare metal industries, our team develops quality management programs and carry out quality tests and inspections. also record the production process and keep track of it.

company has over 26 years of experience in manufacturing processing of non-ferrous rare metals. also have educated many engineers scientists with the expertise needed help in development of industry. also provide a platform employees' development. team experts can provide you with after-sales service as well as support customer Magnesium-lithium alloy, provide technical support solve potential issues with quality. Take appropriate steps improve quality your products and customer service gathering analyzing feedback from customers.

Our company equipped with top-of-the-line production equipment processing equipment and can perform high-end, custom metal processing, fine processing as well as high-difficulty processing. We can manufacture process metal according to specific Magnesium-lithium alloy from the customer and also design drawings. also offer OEM and ODM. research development facility covers more than 500 square meters, with professional R D personnel as well as equipment and facilities that collaborate in development of products and testing.

Suzhou Tamuchuan, processing product Magnesium-lithium alloy in Suzhou manufacturing office area of 2,000 square meters, located there. primary products include rare metals, non-ferrous metals and various other types of metals. We have more than 2,000 partners have cooperation with world's top 500 companies. A specialized R D team available. Stable suppliers can be a fantastic support for large-scale productions, as well as top-of-the-line production equipment and instruments. We have highly skilled quality inspection team strictly control product quality. We have a good collaboration with our partners.

When using Magnesium-lithium Alloy, it is essential to ensure the TMC METAL alloy magnesium highest quality standards at every stage of the process, from material selection to final production. It is also important to adhere to strict safety guidelines to ensure workplace safety and minimize the risk of accidents. The expertise of qualified technicians and engineers is crucial to achieve the desired results and ensure the long-term performance of the final product.

The use of Magnesium-lithium Alloy requires exceptional service to ensure that the material performs optimally in each application. The TMC METAL magnesium metal alloy suppliers that provide this material should be experts in their field, with years of experience in production, quality control, and customer service. Alongside providing the best materials, these suppliers also offer expert advice, technical support, and efficient problem-solving solutions to resolve any issues that may arise in production.