The Next Big Thing in the World of Manufacturing

If you're looking for a strong, reliable, and versatile material to use in your manufacturing projects, then you should definitely consider niobium processing parts. Niobium is a metal that has been used for a variety of applications in the aerospace, medical, and electronics industries. It is also a favorite among jewelry makers due to its beautiful blue-gray color. we will explore the advantages, innovation, safety, use, how to use, service, quality, and application of TMC METAL Niobium processing parts.

Niobium processing parts offer several advantages over other materials used in manufacturing. Firstly, TMC METAL niobium titanium is a highly ductile metal, meaning it can be shaped and formed into various shapes without breaking. Secondly, it has a high melting point, making it resistant to heat and corrosion. Thirdly, it is non-toxic, making it safe for use in medical implants and devices. Lastly, it is highly conductive, which is essential for electronic devices that require efficient flow of electricity.

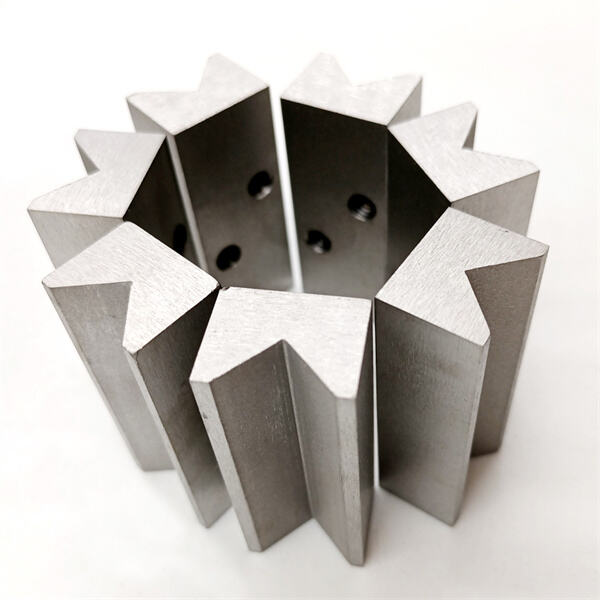

The innovative manufacturing processes employed in the production of niobium parts are what set them apart from other materials. The process of shaping TMC METAL pure niobium involves various techniques such as spinning, drawing, rolling, and welding. This precision and attention to detail in the manufacturing of these parts ensures that they meet the required specifications and are of high quality.

Niobium processing parts are safe for use in medical and other industries due to their non-toxic nature. TMC METAL niobium bar are biocompatible, meaning that the human body can tolerate them without causing any adverse reactions. This makes them an ideal option for use in medical implants such as pacemakers, dental implants, and surgical instruments.

Niobium processing parts are used in various industries, including aerospace, medical, and electronics. In the aerospace industry, TMC METAL niobium wire is used to manufacture parts for aircraft engines, rocket nozzles, and satellite components. In the medical industry, niobium processing parts are used to manufacture implants such as pacemakers, artificial joints, and dental implants. In the electronics industry, it is used to manufacture capacitors, transistors, and other semiconductor devices.

company has more than 26 years' experience in processing and production rare metals non-ferrous alloys. have also educated many personnel in R D and technical with the professional knowledge needed help in the development this industry. also provide a platform employee development. have experienced Niobium processing parts who can provide you with after-sales service assistance to resolve customer issues, provide technical assistance and resolve potential quality issues. Make the necessary changes improve the quality of your products as well as customer service, by gathering and analyzing feedback from clients.

company has established implemented strict quality control process ensure that products conform predetermined standards and specifications. We select suppliers of high-quality in order to guarantee traceability raw materials and the ability control quality Niobium processing parts supply chain. have obtained ISO9001 as well as SGS certifications that are in line with industry standards international standards. In accordance with the specifications of the non-ferrous rare metal industries, our team develops quality management plans and perform quality checks and inspections. We also record and monitor our production processes.

Suzhou Tamuchuan a metal processing product supplier located Suzhou with a production office space of 2,000 square meters which is located in the city. Our main products are rare metals, ferrous metals, various other metals. More than 2,000 companies and partners cooperate with. We also have an Niobium processing parts R D team. The stable suppliers can assist with production on a large scale, with high-end equipment and instruments. We have a professional quality inspection team that able ensure the quality of our products. We have established a good collaboration with partners.

Our company equipped with top-of-the-line production equipment processing equipment and can perform high-end, custom metal processing, fine processing as well as high-difficulty processing. We can manufacture process metal according to specific Niobium processing parts from the customer and also design drawings. also offer OEM and ODM. research development facility covers more than 500 square meters, with professional R D personnel as well as equipment and facilities that collaborate in development of products and testing.

Niobium processing parts are easy to use, and their versatility allows them to be incorporated into various manufacturing processes. TMC METAL niobium and tantalum can be shaped and formed using various techniques such as cutting, drilling, and welding. They can also be treated with various coatings to enhance their corrosion resistance, durability, and aesthetics.

Niobium processing parts are manufactured using high-quality standards to ensure that they meet the required specifications and are of high quality. The TMC METAL niobium tantalum also offer excellent customer service to ensure that clients get the best experience when purchasing these parts. They provide technical support, product advice, and prompt delivery to ensure that clients' needs are met.

Niobium processing parts have a wide range of applications in various industries due to their desirable physical and chemical properties. They are used to manufacture parts for the aerospace, medical, electronics, and jewelry industries. TMC METAL c103 niobium are also used in nuclear reactors, vacuum tubes, and rocket fuel tanks due to their high melting point and corrosion resistance.