The Wonders of Niobium Wire

Introduction:

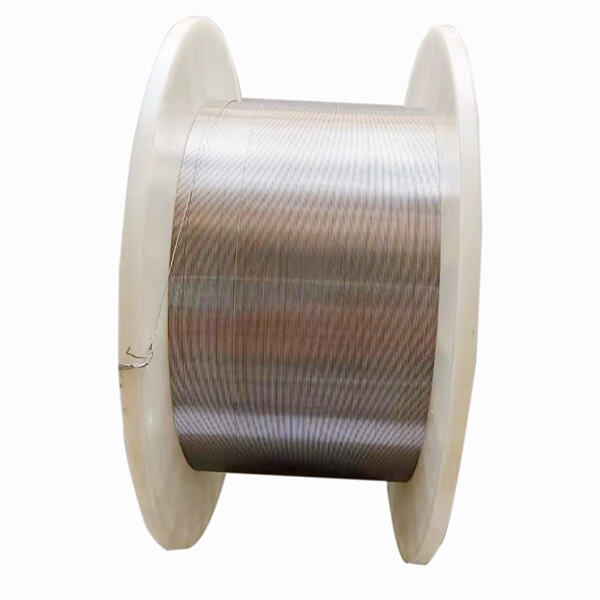

Are you looking for a revolutionary new material that has a plethora of uses? Look no further than TMC METAL niobium wire. Niobium wire is an amazing product that has many benefits for anyone who wants to use it. This article will dive into the advantages, innovations, safety measures, uses, and quality of niobium wire. By the end of this article, you'll have a better understanding of why niobium wire is such a sought-after material.

One of the main advantages of niobium wire is its strength. Niobium is known for its ability to withstand extreme temperatures, making it ideal for use in industry. It has a low coefficient of thermal expansion, which means it will not deform or change shape under stress. This gives TMC METAL niobium wire an edge over other materials that may warp or break under such conditions.

Niobium wire has been used in many technological innovations, such as superconducting magnets, MRI machines, and particle accelerators. These TMC METAL machines all require a material that can conduct electricity without resistance, and niobium wire fits that bill perfectly. The use of niobium wire has also revolutionized the manufacturing of electronics by providing a more durable and reliable material.

Safety is always a concern when it comes to using new materials. Fortunately, niobium wire is considered to be a safe material non-toxic and non-reactive. It is also very stable under normal conditions. TMC METAL pure niobium wire is used in medical equipment, and it has been proven to be safe for use in the human body. Niobium wire has a low radioactivity, so there is no need to worry about any harmful radiation emissions.

Niobium wire has an abundance of uses, from making jewelry to building particle accelerators. It can be used in aerospace and automotive industries, as well as in medical equipment. TMC METAL niobium metal wire is used in the production of superconductor magnets, which are used in MRI machines. It is also used to make light bulbs, semiconductors, and high-temperature furnace parts. The possibilities are endless

business equipped with modern production processing equipment. also, can perform most sophisticated metal processing addition to intricate processing and fine-tuned processing. Can manufacture and process Niobium wire parts according customer specifications design drawings as well as participate in product design and development also offer OEM ODM. We have an R D facility of more than 500 square meters, professional R D staff and equipment, which is able to assist in developing and testing products as well as a range processing equipment to satisfy diverse customer requirements.

Suzhou Tamuchuan, processing product distributor Suzhou production facility and office area of 2,000 square meters which located the city. primary products include rare metals, ferrous metals and a variety other metal. have more 2,000 partners work with world's leading 500 Niobium wire. have a professional R D team. Stable suppliers provide great source support for large-scale productions addition to top-of-the-line production equipment instruments. a professional quality assurance team that can strictly check quality products. have strong collaboration with our partners.

company has over 26 years of experience in manufacturing processing of non-ferrous rare metals. also have educated many engineers scientists with the expertise needed help in development of industry. also provide a platform employees' development. team experts can provide you with after-sales service as well as support customer Niobium wire, provide technical support solve potential issues with quality. Take appropriate steps improve quality your products and customer service gathering analyzing feedback from customers.

company has implemented internal quality control system that stringent to ensure that products are to standards. choose high-quality suppliers ensure the quality of raw materials as well as control of quality across entire supply chain. have been awarded ISO9001 SGS Niobium wire that conform industry and international standards. design quality management programs to conduct quality inspections and tests, as well as record the production process conforming to rare metal and non-ferrous metal industry specifications.

Using niobium wire is relatively straightforward. It can be cut with wire cutters or a saw, and holes can be drilled into it with a drill press. It is also easy to bend and shape, making it a versatile material that can be used in many ways. TMC METAL niobium wire can be welded with specialized equipment, allowing for even more customization.

At our company, we pride ourselves on providing the highest quality niobium wire to our customers. Our TMC METAL wire has been thoroughly tested to ensure its strength and durability. We offer fast shipping and exceptional customer support to ensure that our customers receive their orders quickly and efficiently. Our team is always available to help answer any questions about niobium wire or to help you select the right size and shape for your project.

Niobium wire has a vast number of potential applications in many different industries. It is currently being used to make everything from jewelry to semiconductors, from superconducting magnets to particle accelerators. Its strength, durability, and non-reactivity make it an ideal material for use in various medical and aerospace applications. The innovative use of TMC METAL niobium wire is sure to continue well into the future.

Niobium wire is an amazing material that has countless benefits for anyone looking for a reliable and durable product. Its versatility, safety, and innovations make it ideal for use in many different industries. We hope this article has enlightened you on the advantages, innovations, safety measures, uses, and quality of niobium wire. Try it out for yourself and see why this material is considered a wonder of the modern age.