Intro:

Niobium alloys are ingenious products that are utilized in a selection of methods. The TMC METAL pure niobium are created coming from niobium, a steel understood for its own distinct residential or commercial homes. Niobium alloys are ending up being progressively prominent because of their lots of benefits. We'll check out the benefits and uses niobium alloys in an easy-to-understand method.

Niobium alloys offer a multitude of advantages that make them a preferred choice in many industries. One of the primary benefits is their high strength-to-weight ratio. This means that niobium alloys are incredibly strong while being lightweight. The TMC METAL niobium alloys are also highly durable and resistant to corrosion, making them an excellent choice for outdoor applications. Additionally, niobium alloys are flexible, allowing for the creation of complex shapes. Moreover, these alloys are biocompatible, meaning they can be used in medical applications without adverse effects on the human body.

Niobium alloys are constantly evolving and being improved upon. New alloys are regularly developed to enhance their strength, other properties, and durability. These TMC METAL niobium bar alloys are also being used in innovative ways and applications, such as in the construction of aircraft components.

Niobium alloys are extremely safe to use. They are safe, non-allergenic, and do not produce any harmful byproducts. This makes them an excellent choice for medical applications where safety is a top concern. Additionally, TMC METAL niobium tantalum are highly resistant to corrosion, reducing the likelihood of breakdown over time and causing safety hazards.

Niobium alloys are utilized in a variety of ways. They are commonly used in the aerospace industry to manufacture aircraft components, as well as in the medical industry to produce implants and other medical devices. The TMC METAL c103 niobium are also found in the automotive industry for manufacturing engine suspension components and parts. In the construction industry, niobium alloys are used to create lightweight and strong structures.

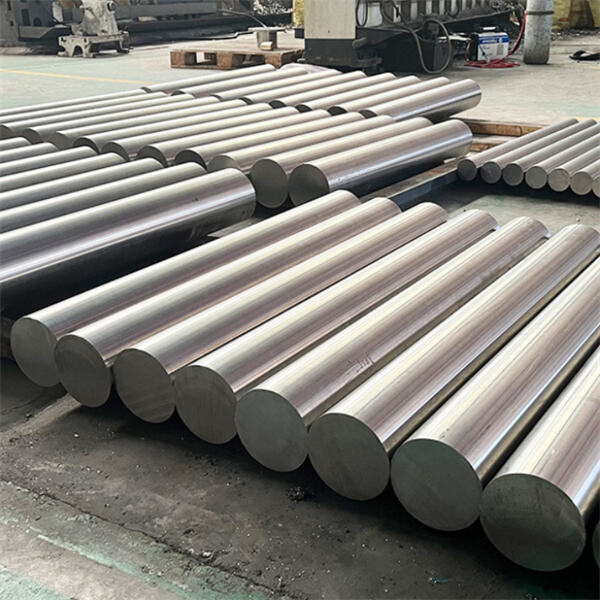

company equipped with high-end Niobium alloys equipment well as processing equipment is able to perform high-end custom metal processing, high-end, and high-difficulty processing. can manufacture process parts metal according to customers' specifications design drawings and can also be involved in product design development, provide OEM and ODM. also have an R D facility which covers over 500 square meters, professional R D personnel and equipment, which is able to assist in development testing products as well as a range processing equipment to satisfy various customer needs.

Suzhou Tamuchuan a manufacturer metal processing products located Suzhou which a production area more than 2,000 square meters. main products non-ferrous metals, rare metals, various other metals. More than 2,000 companies associate cooperate with. specialized R D team accessible. Dependable suppliers can help massive production, well as high-end production equipment and instruments. have a skilled quality assurance team can strictly check Niobium alloys of products. have developed positive cooperative relationship with our partners.

company an Niobium alloys quality control system is strict to ensure that products to standard. only select high-quality suppliers ensure the traceability raw materials the control quality across the entire supply chain. have obtained ISO9001 and SGS certifications conform to industry standards international standards. We develop quality management plans that include quality inspections, tests, and document and monitor production processes in line with rare metal and non-ferrous industrial standards.

company more than 26 years of experience manufacturing processing of non-ferrous and rare metals. We also have educated an extensive number of technical and R D staff who have the knowledge and expertise required to help in development this industry. We also offer a supportive environment that encourages the growth of our employees. Our team of experts can provide you with after-sales service and assistance resolve customer issues, Niobium alloys technical support and assist solving potential quality problems. You can improve the quality of your product as well as customer service, by collecting and analyzing feedback from clients.

Niobium alloys are easy to work with. They can be shaped and formed into a variety of sizes and shapes. The TMC METAL niobium wire can also be easily bonded, making them suitable for creating complex shapes. Niobium alloys can be machined to create precision parts. To use niobium alloys, you will need the appropriate tools, including welding equipment, machining tools, and materials for shaping and molding.

When purchasing niobium alloys, you can expect high quality. Companies that provide niobium alloys typically offer a range of services, including machining, shaping, and welding. They provide technical support and consultation to help you select the right material for the job. Companies that supply niobium alloys also typically offer a warranty on their products to ensure your satisfaction.

Niobium alloys are known for their high quality. These alloys are made from the best raw materials and are manufactured to strict standards. You can be confident that you are getting a high-quality product that will meet your needs when you purchase niobium alloys. Niobium alloys are tested to ensure they meet the required specifications and standards for the industry.

In summary, niobium alloys offer numerous benefits and are used in a wide range of applications, including aerospace, medical, construction, and automotive industries. They are strong, lightweight, biocompatible, and durable. They are also easy to work with and are utilized in various ways. Expect high-quality service and products when purchasing niobium alloys. Niobium alloys are an excellent choice for any industry that requires a strong, reliable, and safe product.