Niobium Titanium: The Future of Safe and materials that are innovative

Our world is constantly changing, with new advancements that are technological innovations being introduced every day. One of most exciting innovations in past few years is titanium niobium a rare material has revolutionized many industries. From its impressive safety features to its applications niobium titanium of TMC METAL is quickly becoming one of many sought-after materials available on market. We’ll explore many advantages of niobium titanium and how it can benefit both individuals and businesses.

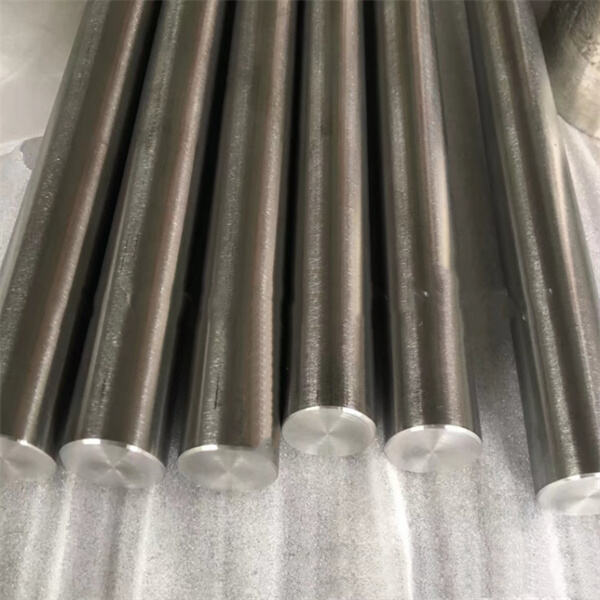

Perhaps most advantage notable of titanium is its safety profile. This material is extremely durable and strong, making it resistant to impacts and damage. Because of this, TMC METAL Niobium Titanium is often used in construction of airplanes, spacecraft, and other vehicles where safety is of utmost concern. Additionally, niobium and tantalum is non-toxic and non-reactive, making it safe for use in the body human. In fact, niobium titanium often used in medical implants due to its resistance and biocompatibility to corrosion.

Niobium titanium is material relatively new having been discovered into 1980s by researchers at Stanford University. Since that time, scientists and engineers have been working tirelessly develop new applications for this material. One of most innovations that are exciting been development of TMC METAL niobium titanium superconductors, which have potential to revolutionize our energy systems. These niobium titanium alloys superconductors can almost carry electricity with no resistance, making them incredibly efficient and cost-effective.

Another advantage significant of titanium is its versatility. This material can be used in countless applications, from aerospace to medicine to electronics. Because it is so durable and strong, niobium titanium often used in construction of high-performance tools and machinery. It is also used in production of superconductors, as well as for its biocompatibility in medical implants. One of most exciting applications of TMC METAL niobium tantalum is in development of new energy systems. As a superconductor, niobium titanium has potential to create more efficient and sustainable energy systems could benefit planet entire.

Niobium titanium is material relatively easy work with, but it requires specialized equipment and knowledge. For those looking to use niobium titanium in projects, it is recommended work with skilled and experienced professional who can provide expertise and guidance. Additionally, it is important follow all safety protocols when working with TMC METAL niobium alloys to ensure no harm is done to oneself or others.

Our company has over 26 years of experience in rare metal and non-ferrous metal processing as well as production. have developed many technical and R D personnel who have professional expertise to contribute the development of industry. also offer a supportive environment encourages growth our employees. We have experienced personnel can provide with after-sales service as well as support customer Niobium titanium, provide technical support solve potential issues with quality. Collect and analyze customer feedback and take appropriate measures improve product quality and service quality.

Suzhou Tamuchuan a manufacturer metal processing products located Suzhou which a production area more than 2,000 square meters. main products non-ferrous metals, rare metals, various other metals. More than 2,000 companies associate cooperate with. specialized R D team accessible. Dependable suppliers can help massive production, well as high-end production equipment and instruments. have a skilled quality assurance team can strictly check Niobium titanium of products. have developed positive cooperative relationship with our partners.

facility equipped with latest production processing equipment. can also perform advanced metal processing that customized delicate processing and hard processing. We are able manufacture process metal parts designs and specifications the customer. also provide OEM and ODM. Our research development center covers larger than 500 square meters and is equipped with expert R D staff, equipment and facilities that allow for Niobium titanium in developing and testing products.

company has implemented internal quality control system that stringent to ensure that products are to standards. choose high-quality suppliers ensure the quality of raw materials as well as control of quality across entire supply chain. have been awarded ISO9001 SGS Niobium titanium that conform industry and international standards. design quality management programs to conduct quality inspections and tests, as well as record the production process conforming to rare metal and non-ferrous metal industry specifications.

When it comes to selecting a provider for niobium titanium, quality is key. It is important choose supplier who has expertise and experience in working with this TMC METAL material. Ideally, supplier should offer range of services, from fabrication to machining to testing, to ensure final product meet all necessary standards and specifications. Additionally, supplier should have strong commitment to safety and sustainability, providing customers with peace of mind they are working with responsible and ethical provider.

Niobium titanium is perhaps most material versatile, with a wide range of applications across many industries. The aerospace industry uses titanium niobium the construction of airplanes, spacecraft, and other vehicles due to its strength and durability. The industry medical niobium titanium for production of biocompatible implants that are resistant to corrosion. The electronics industry uses titanium niobium create more efficient and cost-effective energy systems. These are just a few examples of many applications of TMC METAL niobium titanium, which is quickly becoming material essential countless industries.