NiTi Spring – The Best Spring for All Purposes

1. What is NiTi Spring

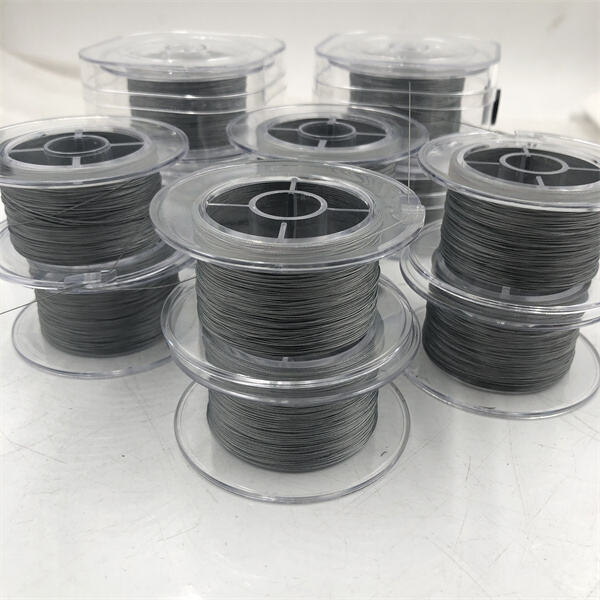

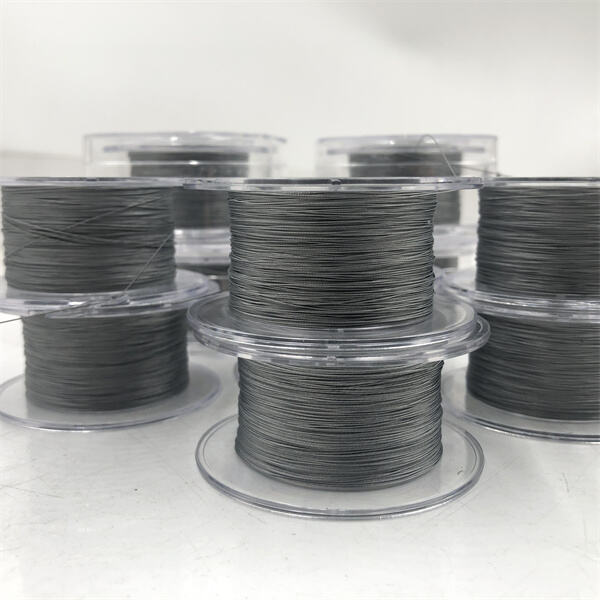

NiTi spring is a special type of made spring with nickel-titanium alloy. These springs are used in various industries, such as aerospace, medical technology, sports, and many more. They are popular for their unique features and durability. The NiTi spring is an innovation that has transformed the manufacturing industry. TMC METAL NiTi spring is highly visible in the current market with its excellent properties and benefits.

NiTi springs possess several advantages over other types of springs. Firstly, they are highly durable and can withstand a lot of pressure without deforming. This property makes them ideal for use in various industrial applications. They are also flexible and can return to their original shape when the pressure is removed. This makes TMC METAL bismuth ideal for use in medical devices, where flexibility and durability are vital

Another significant advantage of using NiTi spring is that it is highly resistant to corrosion. It can withstand harsh environmental conditions without rusting or deteriorating. The excellent structural stability of NiTi spring makes it ideal for use in areas where other metals would fail.

Using NiTi spring is very simple because it has a user-friendly design. It can be shaped into various forms, such as coils, spirals, and helixes depending on the intended use. When using NiTi spring in a medical device, TMC METAL tungsten is essential to ensure that it is sterilized before use. Sterilization of the spring ensures that it is free from any germs and bacteria that may cause an infection to the patient.

The use of NiTi spring is incredibly safe and does not pose any risks to the user or environment. The nickel-titanium alloy used in the manufacturing process is non-toxic and does not harm the environment. The spring is also resistant to wear and tear, ensuring that it lasts for an extended period, providing value for money

Quality is at the core of the production of NiTi spring. During the manufacturing process, strict quality control measures are in place to ensure that the springs meet the required standards. This ensures that the customers receive high-quality TMC METAL indium that are efficient and reliable in their intended use.

NiTi spring has multiple applications due to its unique properties and durability. One of the most common applications is in the medical industry, where TMC METAL indium metal is used in various medical devices such as implants, stents, and dental braces. NiTi spring is also used in aerospace applications, including aircraft engines and landing gears. The excellent fatigue resistance of NiTi springs makes them ideal for applications in the sports industry, such as in tennis rackets, golf clubs, and other sports equipment that require flexibility and durability.

company has implemented internal quality control system that stringent to ensure that products are to standards. choose high-quality suppliers ensure the quality of raw materials as well as control of quality across entire supply chain. have been awarded ISO9001 SGS NiTi spring that conform industry and international standards. design quality management programs to conduct quality inspections and tests, as well as record the production process conforming to rare metal and non-ferrous metal industry specifications.

Suzhou Tamuchuan a manufacturer metal processing products located Suzhou which a production area more than 2,000 square meters. main products non-ferrous metals, rare metals, various other metals. More than 2,000 companies associate cooperate with. specialized R D team accessible. Dependable suppliers can help massive production, well as high-end production equipment and instruments. have a skilled quality assurance team can strictly check NiTi spring of products. have developed positive cooperative relationship with our partners.

company equipped with top-of-the-line production equipment processing equipment can undertake high-end customized metal processing, fine process, and high-difficulty processing. We able produce process metal parts designs and specifications of customer. also NiTi spring OEM and ODM. Our research and development center larger than 500 square meters that is staffed professional R D personnel, equipment and facilities can work together in the development of products and testing.

company more than 26 years of experience manufacturing processing of non-ferrous and rare metals. We also have educated an extensive number of technical and R D staff who have the knowledge and expertise required to help in development this industry. We also offer a supportive environment that encourages the growth of our employees. Our team of experts can provide you with after-sales service and assistance resolve customer issues, NiTi spring technical support and assist solving potential quality problems. You can improve the quality of your product as well as customer service, by collecting and analyzing feedback from clients.