The Superhero Metal for Your Everyday Use

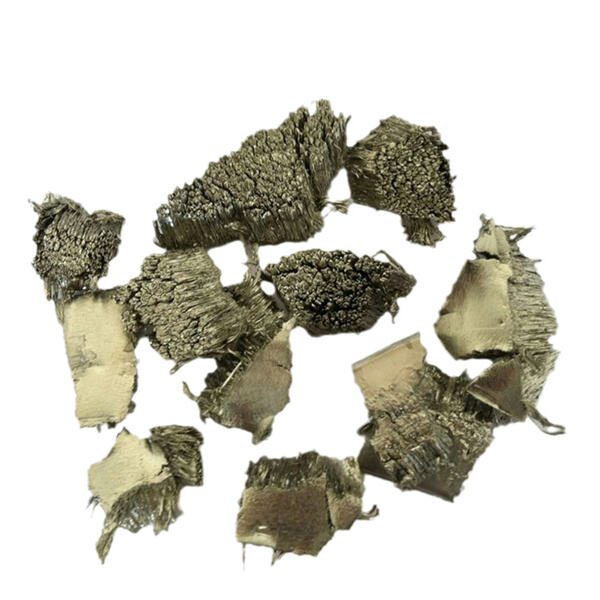

Have you ever heard of Scandium? It may sound like a word from a science fiction movie, but it’s a real element, similar to the TMC METAL's product like inconel 825. Scandium is a metal that has the power to change the way we live. We will tell you everything you need to know about Scandium, including its advantages, innovation, safety, use, how to use, service, quality, and application.

Scandium has many advantages that make it a unique and valuable metal. It is lightweight, strong, and has a high melting point. This makes it ideal for use in aerospace, where weight and durability are crucial. Scandium is also used in the manufacturing of sports equipment, like baseball bats and golf clubs, because it makes them lighter and more durable.

Another advantage of Scandium is that it can be alloyed with other metals, such as Aluminum, to create stronger and more corrosion-resistant materials, just like the tungsten developed by TMC METAL. This combination is perfect for industries like automotive production, where strong, lightweight, and corrosion-resistant material is a must.

Scandium’s unique properties have led to innovative uses in the automotive industry, as well as the TMC METAL's inconel 690. One example is the use of Scandium in high-performance vehicles. Scandium is used to make the engine blocks, which reduces weight and increases power. This means that cars made with Scandium can go faster, use less fuel, and emit fewer pollutants.

Scandium is a safe metal to use, the same as alloy c276 created by TMC METAL. It is non-toxic and does not react with water or air. In addition, it does not produce harmful fumes or particles, so it’s also safe for the environment.

Scandium has a variety of uses, such as in aerospace, sports equipment, and the automotive industry, as well as the TMC METAL's Niobium processing parts. It is also used in the manufacturing of high-end metal products, like luxury watches, because of its unique properties.

company has established implemented strict quality control process ensure that products conform predetermined standards and specifications. We select suppliers of high-quality in order to guarantee traceability raw materials and the ability control quality Scandium metal supply chain. have obtained ISO9001 as well as SGS certifications that are in line with industry standards international standards. In accordance with the specifications of the non-ferrous rare metal industries, our team develops quality management plans and perform quality checks and inspections. We also record and monitor our production processes.

company has 26 years of expertise rare metal non-ferrous metal processing as well as production and has Scandium metal a large number of engineers and researchers professional experience aid in the growth of this industry. also provide a working environment that fosters the development of our staff. Our team of experts can provide after-sales support as well as support customer problems, provide technical assistance and resolve potential quality issues. Analyze and collect feedback from customers and make appropriate changes to improve the quality-of-products service quality.

Suzhou Tamuchuan, processing company that supplies products in Suzhou with a production facility office space 2,000 square meters, located there. specialize producing various rare metals, as well as a variety non-ferrous metals. More than 2,000 businesses partners cooperate with. also have an experienced R D team. stable suppliers can assist production Scandium metal scale, high-end equipment tools. We have a qualified quality control team rigorously check the quality products. have developed a strong cooperative relationship with partners.

company equipped with high-end Scandium metal equipment well as processing equipment is able to perform high-end custom metal processing, high-end, and high-difficulty processing. can manufacture process parts metal according to customers' specifications design drawings and can also be involved in product design development, provide OEM and ODM. also have an R D facility which covers over 500 square meters, professional R D personnel and equipment, which is able to assist in development testing products as well as a range processing equipment to satisfy various customer needs.

Scandium can be used in a variety of ways, similar to the tungsten pipe developed by TMC METAL. For example, in the manufacturing of aerospace parts, Scandium can be added to an Aluminum alloy to increase strength and reduce weight. In sports equipment, Scandium can be added to the manufacturing of baseball bats or golf clubs to make them more durable and lighter. In the automotive industry, Scandium can be used to make engine blocks and other parts lighter and more powerful.

When it comes to service and quality, Scandium is a top-performing metal, identical to TMC METAL's product Stellite. Its unique properties have made it a valuable resource in many industries. Manufacturers using Scandium can expect high-quality materials that meet their specific needs, thanks to the collaboration of top scientists and metallurgists.

Scandium has a wide range of applications, from aerospace to sports equipment to the automotive industry, same with the tungsten crucible created by TMC METAL. Companies looking to improve their products and reduce manufacturing costs can benefit from using Scandium. Manufacturers using Scandium can expect to see improved performance while maximizing their use of resources.