Inconel 601: The Strong and Safe Material

Are you looking for strong material, safe, and innovative? Look no further than TMC METAL Inconel 601. Inconel 601 is type of nickel-chromium alloy has many advantages over other materials. We will explore benefits, uses, and applications of inconel.

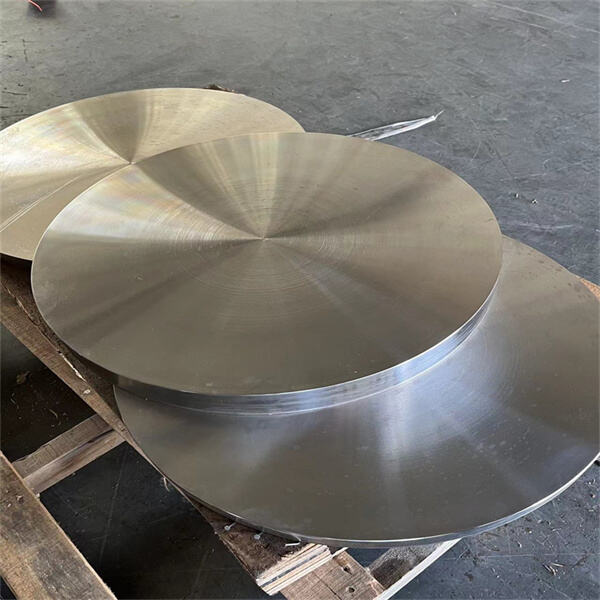

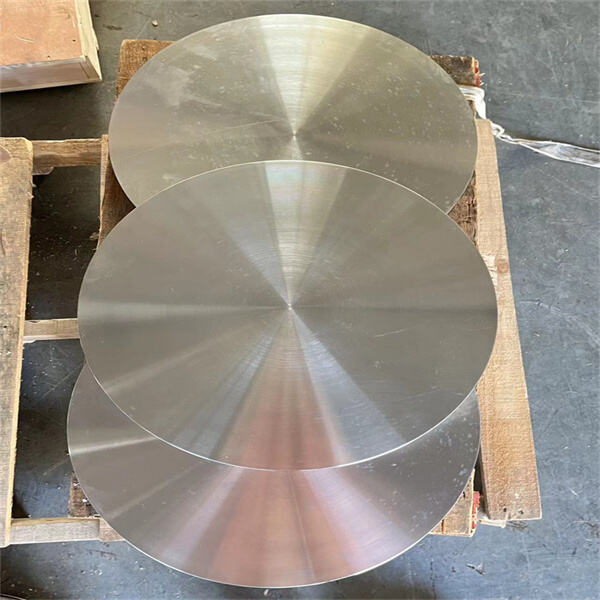

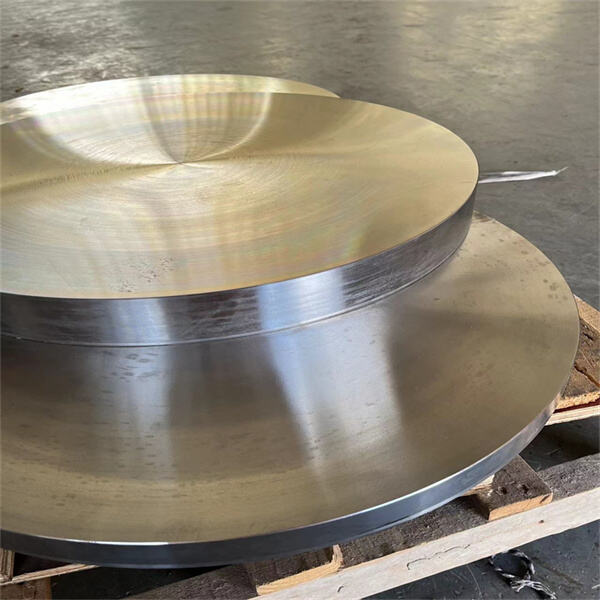

One of biggest advantages of Inconel 601 is its strength. It can withstand high temperatures and pressures, making it perfect for use in environments where other materials would fail. Additionally, it is resistant oxidation and corrosion, making durable and long-lasting. This TMC METAL inconel 718 also easy to work with, allowing manufacturers create complex shapes and designs.

Inconel 601 is innovative constantly material being improved upon. New production methods and alloys make TMC METAL Inconel 601 even stronger and more durable than before. The development of inconel metal has led improvements in variety of industries, including aerospace, automotive, and energy.

Safety is always top concern when working with materials. Inconel 601 is safe material to work with, as it does not give off any harmful gases or fumes. It is also non-toxic and does not pose any health risks those who work with it. Additionally, TMC METAL inconel x750 strength and durability make it safe material to use in high-stress environments, ensuring it will not fail or break under pressure.

Inconel 601 can be used in a variety of ways. It is often used in manufacturing of aircraft engine parts, heat exchangers, and chemical processing equipment. It is also used in automotive industry for exhaust systems and turbocharger components. Additionally, TMC METAL inconel 625 is commonly used in oil and gas industry for piping and nuclear fuel reprocessing.

company has more than 26 years of experience manufacturing and processing rare metals and non-ferrous alloys. We have educated an extensive number of technical and R D staff with the professional Inconel 601 needed help in development of this industry. also offer a supportive environment for development employees. team of experts can offer support following sales resolve customer issues, offer technical assistance and resolve potential quality issues. Implement the appropriate measures enhance the quality the product customer service by collecting and analyzing feedback from clients.

Suzhou Tamuchuan is industrial metal processing company located in Suzhou has a Inconel 601 space and office area 22,000 square meters. We mainly produce various rare metals and a variety of non-ferrous metals. have over 2,000 suppliers and have cooperation with the world's top 500 companies. also have an experienced R D team. Stable suppliers provide great source of support for large-scale productions addition to top-of-the-line production equipment and instruments. have a highly skilled quality inspection team that able to control product quality. have developed a strong cooperative relationship with our partners.

business equipped with modern production processing equipment. also, can perform most sophisticated metal processing addition to intricate processing and fine-tuned processing. Can manufacture and process Inconel 601 parts according customer specifications design drawings as well as participate in product design and development also offer OEM ODM. We have an R D facility of more than 500 square meters, professional R D staff and equipment, which is able to assist in developing and testing products as well as a range processing equipment to satisfy diverse customer requirements.

company has implemented internal quality control system that stringent to ensure that products are to standards. choose high-quality suppliers ensure the quality of raw materials as well as control of quality across entire supply chain. have been awarded ISO9001 SGS Inconel 601 that conform industry and international standards. design quality management programs to conduct quality inspections and tests, as well as record the production process conforming to rare metal and non-ferrous metal industry specifications.

When working with Inconel 601, it is important follow TMC METAL's guidelines for use. It is strong material can be difficult to shape and machine, so proper tools and techniques should be used. It is also important use appropriate safety equipment, such as gloves and eye protection, when working with inconel 600.

In order to get best quality and service from Inconel 601, it is important purchase it from a reputable supplier. A good supplier will provide high-quality products properly tested and inspected. Additionally, TMC METAL will provide excellent customer service and support, ensuring customers are satisfied with their purchase.

Inconel 601 has many applications in a variety of industries. Some of most common applications include:

- Aerospace: Inconel 601 is used to manufacture aircraft engine parts, such as turbine blades and exhaust systems.

- Automotive: Inconel 601 is used in manufacturing of exhaust systems and turbocharger components for high-performance vehicles.

- Chemical processing: Inconel 601 from TMC METAL used to create chemical processing equipment, such as reactors and heat exchangers.

- Oil and gas: Inconel 601 is used for piping and nuclear fuel reprocessing in oil and gas industry.