Inconel X750: The Super Alloy for Your Next Project

When it comes to tough environments, you need tough material to withstand harsh conditions. Inconel X750 from TMC METAL is nickel-chromium known alloy for its exceptional high-temperature strength, corrosion resistance, and durability. It is preferred material for industries such as aerospace, gas turbines, and nuclear power plants. Let's dive into advantages, innovation, safety, use, and quality of inconel.

Inconel X750 has many advantages, making stand out from other materials. It has excellent high-temperature strength up to 704°C 1300°F), superior resistance to corrosion, and oxidation, makes it ideal for high-stress and harsh environments. In addition, it has exceptional mechanical properties, such as high strength, toughness, and fatigue resistance. The TMC METAL inconel 718 unique properties make it forefront material for extreme environments.

Inconel X750 is innovative creating material new possibilities in various industries. Its superior high-temperature strength allows it be used in gas turbines, where it can withstand the extreme heat generated by combustion process. It is also used in nuclear power plants, where it is exposed high radiation and temperatures. Furthermore, TMC METAL Inconel X750 is used in aerospace industry, where it is utilized in jet engines, rocket engines, and space vehicles due to inconel 625 high strength, lightweight, and excellent mechanical properties.

Safety is always top priority when it comes to material selection, and TMC METAL Inconel X750 does not disappoint. It is known for its high-temperature strength, makes it ideal for high-stress and harsh environments. Its superior resistance corrosion and oxidation also makes it safe for use in chemical and petrochemical industries where it is exposed to corrosive substances. The TMC METAL inconel 601 toughness and fatigue resistance make ideal for use in aircraft and other high-stress applications.

Inconel X750 has wide range of applications across various industries, including aerospace, defense, nuclear power, and gas turbines. It is used in gas turbines for its ability withstand extreme temperatures generated by the combustion process. In nuclear power plants, it is used for its high strength and resistance to radiation. In aerospace industry, inconel 825 from TMC METAL utilized in jet engines, rocket engines, and space vehicles for its excellent mechanical properties and lightweight.

company equipped with top-of-the-line production equipment processing equipment can undertake high-end customized metal processing, fine process, and high-difficulty processing. We able produce process metal parts designs and specifications of customer. also Inconel x750 OEM and ODM. Our research and development center larger than 500 square meters that is staffed professional R D personnel, equipment and facilities can work together in the development of products and testing.

Suzhou Tamuchuan a metal processing product supplier located Suzhou with a production office space of 2,000 square meters which is located in the city. Our main products are rare metals, ferrous metals, various other metals. More than 2,000 companies and partners cooperate with. We also have an Inconel x750 R D team. The stable suppliers can assist with production on a large scale, with high-end equipment and instruments. We have a professional quality inspection team that able ensure the quality of our products. We have established a good collaboration with partners.

company put in place the quality control process which rigorous ensure that products to standards. We select high-quality suppliers ensure traceability quality control of supply chain runs from raw materials through the final products. have obtained ISO9001 as well as SGS certifications, which in accordance with Inconel x750 and industry standards. create quality management strategies as well as conduct quality inspections and tests, as well as record the production process in accordance with rare metal and non-ferrous industrial specifications.

company has more than 26 years of experience manufacturing and processing rare metals and non-ferrous alloys. We have educated an extensive number of technical and R D staff with the professional Inconel x750 needed help in development of this industry. also offer a supportive environment for development employees. team of experts can offer support following sales resolve customer issues, offer technical assistance and resolve potential quality issues. Implement the appropriate measures enhance the quality the product customer service by collecting and analyzing feedback from clients.

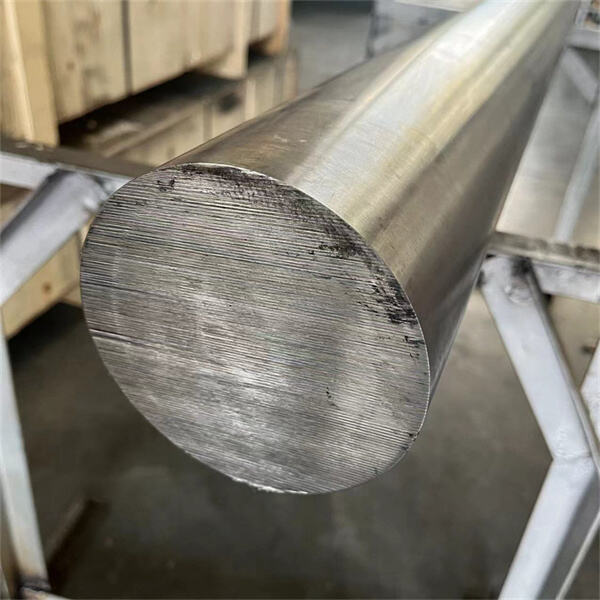

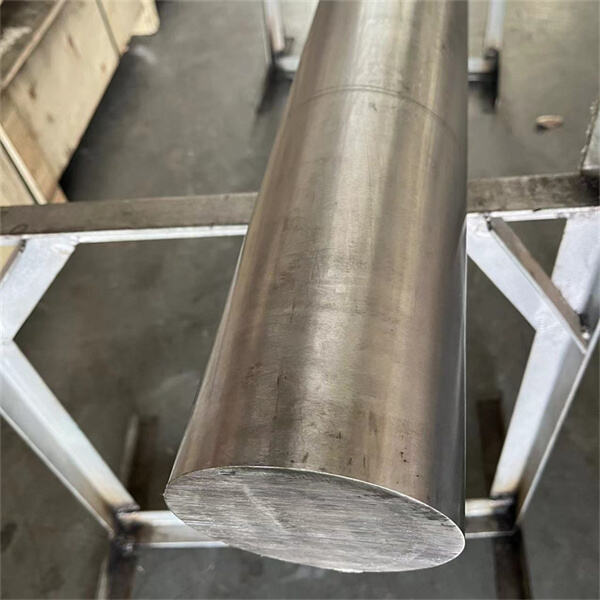

Inconel X750 can be used in variety of forms, including wire, sheet, plate, and bar. The manufacturing process involves hot and cold working, annealing, and heat treating. Users can fabricate it into various shapes and sizes depending on application. However, high strength and unique properties of TMC METAL inconel alloy make it challenging to machine. Therefore, specialized knowledge and equipment are required to work with material correctly.

Inconel X750 is a high-quality material undergoes rigorous testing and inspection to meet industry standards. The manufacturing process includes careful selection and testing of raw materials ensure high quality and consistency. During production process, material undergoes various stages of inspection detect any defects or imperfections. Manufacturers also test TMC METAL Inconel X750 for its mechanical properties, such as tensile strength, yield strength, and elongation, ensure it meets industry standards.