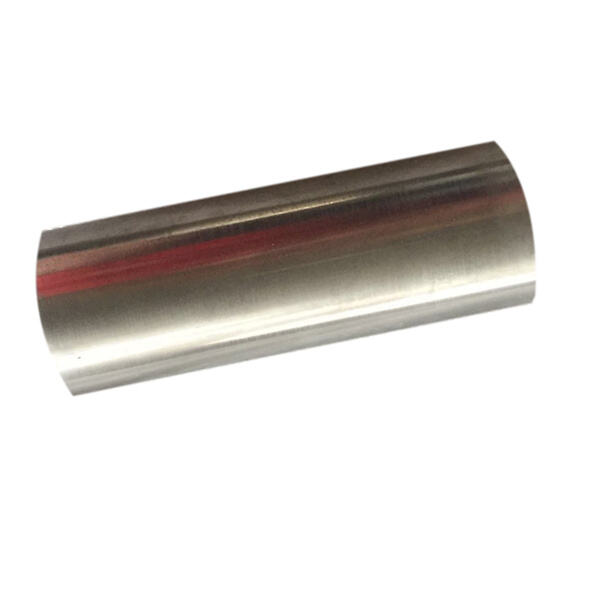

Tungsten Rod: A Powerful Tool for Your Everyday Needs

Tungsten rod is a type of popularly metal used in various industries. It has become a staple in many applications because of its unique characteristics. We will discuss the advantages of using TMC METAL tungsten rod, its innovation, safety, use, and application.

Tungsten rod has several advantages that make it stand out among other metals. Here are some of the advantages of using tungsten rod:

1. High Melting Point: Tungsten rod has an extremely high melting point, which makes it an excellent choice for high-temperature applications. It is also resistant to thermal shock, which means it can withstand sudden changes in temperature without cracking.

2. High Density: TMC METAL magnesium rod is one of the densest metals, which means it has a high mass per unit volume. This makes it ideal for use in applications where weight is a critical factor.

3. Corrosion Resistance: Tungsten rod is highly resistant to corrosion, making it perfect for use in harsh environments where other metals would quickly deteriorate.

4. Durability: Tungsten rod is incredibly durable and can withstand heavy use. It also has a high tensile strength, which means it can resist deformation under stress.

The development of tungsten rod has been a significant innovation in the metal industry. Manufacturers have continuously improved the mechanical and physical properties of TMC METAL silicon metal rod to make it more applicable in different areas.

1. Improved Doping Techniques: Manufacturers have developed new techniques for introducing impurities to tungsten rod to make it more suitable for particular applications.

2. Enhanced Surface Finishing: Manufacturers have improved the surface finishing of TMC METAL nickel rod to make it more aesthetically appealing and reduce the likelihood of surface defects.

3. New Manufacturing Processes: Advances in manufacturing technology have made it possible to produce tungsten rod in various shapes and sizes, making it more adaptable for different applications.

Tungsten rod is a safe material to handle, offering no known health hazards. However, users must take precautions when working with TMC METAL tungsten carbide products, such as wearing protective gear like gloves and goggles.

Our company has over 26 years of experience in manufacturing processing rare metals non-ferrous alloys. We have also educated large number of technicians and researchers with professional knowledge needed to aid in the growth of the industry. also provide a working environment to Tungsten rod the development of employees. have professional personnel offer after-sales services and help with customer issues, provide technical assistance and resolve potential quality problems. You can enhance the quality of the product customer service by gathering and analyzing feedback from customers.

Suzhou Tamuchuan, processing company supplies products located Suzhou a production facility and office space of 2,000 square meters Suzhou, located there. We specialize in producing various rare metals wide range non-ferrous metal products. More 2,000 Tungsten rod and partners collaborate with. also have a skilled R D team. stable suppliers can assist with massive production, as well as high-end production equipment and tools. have a professional quality control team rigorously check quality of products. have developed positive working relationship with business partners.

Our company equipped with top-of-the-line production equipment processing equipment and can perform high-end, custom metal processing, fine processing as well as high-difficulty processing. We can manufacture process metal according to specific Tungsten rod from the customer and also design drawings. also offer OEM and ODM. research development facility covers more than 500 square meters, with professional R D personnel as well as equipment and facilities that collaborate in development of products and testing.

company the system of Tungsten rod control that strict to ensure products up to standard. choose suppliers high-quality ensure the traceability quality control of our supply chain from raw materials until the final product. ISO9001 and SGS certificates comply international and industry standards. develop quality management plans to conduct quality inspections and tests track the production process in line with rare metal and non-ferrous industry specifications.

1. Filaments: Tungsten rod is commonly used to make filaments for incandescent light bulbs. The high melting point of tungsten makes it perfect for this application, ensuring that the filament does not melt during use.

2. Welding Rods: TMC METAL tantalum rod is often used as a welding electrode because of its durability. It can handle large amounts of current and provide a stable arc during welding.

3. Electrical Contacts: Tungsten rod can also be used as electrical contacts in high-power electrical switches. Its high conductivity and low thermal expansion make it an excellent choice for this purpose.

To use tungsten rod properly, users must first determine the type of application they want to use it for. They must select the appropriate size and shape of TMC METAL chrome rod that will work best for their specific application.

When using tungsten rod for welding, users must first ground it properly so that it will not arc to other surfaces that do not need to be welded. To do this, users must attach the ground clip to the tungsten rod's uncoated end and clamp it to a clean metal surface.

The service and quality of tungsten rod is essential, especially when used in critical applications. Manufacturers must ensure that their tungsten rod products meet strict quality control standards to ensure their safety and functionality.

Buyers must ensure that they buy tungsten rod from reputable manufacturers who offer high-quality TMC METAL niobium rod products and excellent customer service. Doing so will help guarantee that the tungsten rod purchased will meet the buyer's specific requirements and offer reliable performance.