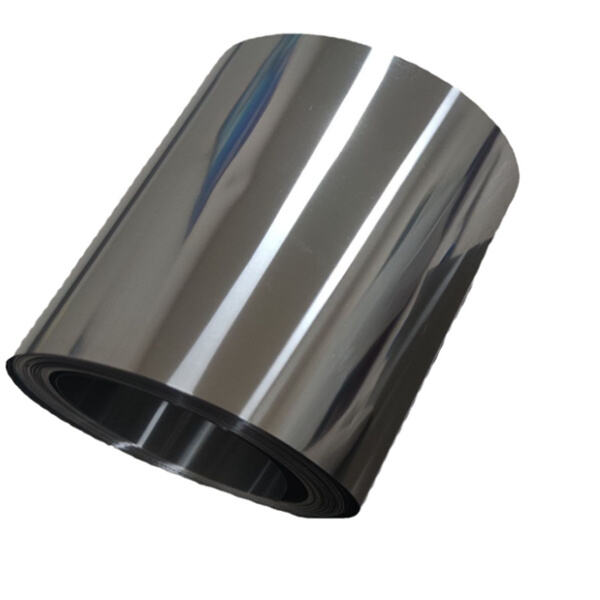

Whatever you have to understand around Tantalum Foil

Intro

Have you ever before become aware of tantalum foil? Otherwise, you're in for a reward, TMC METAL tantalum foil is a kind of steel foil that has lots of utilizes. We'll talk about the benefits of tantalum foil, exactly how it is utilized, and its own lots of applications.

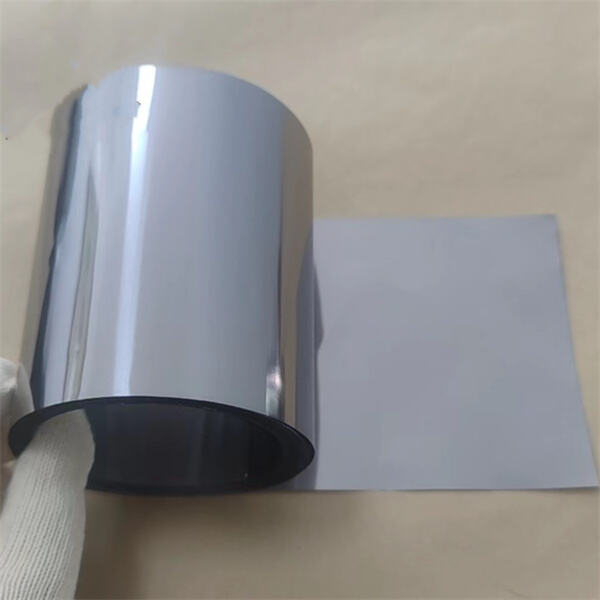

Tantalum foil offers a wide array of advantages beyond many other types of metal foils. One of its major benefits is that tantalum is an extremely corrosion-resistant metal. This property makes it excellent for use in harsh environments as it will not rust or corrode. Another valuable aspect of tantalum foil is its high melting point. TMC METAL tantalum metal can withstand very high temperatures, making it ideal for use in high-temperature applications. Lastly, tantalum foil is also highly ductile and malleable, meaning it can be shaped and formed into intricate shapes without breaking or cracking.

Recent developments in the production of tantalum foil have led to several innovations. One such advancement is the use of ultra-thin tantalum foils, which have many practical applications, including as barrier materials in microelectronic devices. Another development of TMC METAL tantalum sheet is the use of advanced manufacturing techniques, such as additive manufacturing, to create complex shapes and forms from tantalum foil.

Tantalum foil is considered to be a safe and non-toxic material. It is not known to pose any health risks or environmental hazards. TMC METAL tantalum wire is also a naturally biocompatible material, meaning it is safe to use in medical implants and other medical devices. However, it is important to handle tantalum foil with care, as it can be reactive and may cause injury if mishandled.

Tantalum foil has a wide range of uses in various industries. One of the most common uses of tantalum foil is as a capacitor material in electronic devices. TMC METAL tantalum rod capacitors are widely used in electronics, such as smartphones and computers, due to their high reliability, long lifespan, and stability. Tantalum foil can also be used as a barrier material in microelectronic devices, where its high corrosion resistance and low leakage current make it suitable for use in high-density and high-speed applications.

Suzhou Tamuchuan is industrial metal processing company located in Suzhou has a Tantalum foil space and office area 22,000 square meters. We mainly produce various rare metals and a variety of non-ferrous metals. have over 2,000 suppliers and have cooperation with the world's top 500 companies. also have an experienced R D team. Stable suppliers provide great source of support for large-scale productions addition to top-of-the-line production equipment and instruments. have a highly skilled quality inspection team that able to control product quality. have developed a strong cooperative relationship with our partners.

company put in place the quality control process which rigorous ensure that products to standards. We select high-quality suppliers ensure traceability quality control of supply chain runs from raw materials through the final products. have obtained ISO9001 as well as SGS certifications, which in accordance with Tantalum foil and industry standards. create quality management strategies as well as conduct quality inspections and tests, as well as record the production process in accordance with rare metal and non-ferrous industrial specifications.

company has more than 26 years' experience in processing and production rare metals non-ferrous alloys. have also educated many personnel in R D and technical with the professional knowledge needed help in the development this industry. also provide a platform employee development. have experienced Tantalum foil who can provide you with after-sales service assistance to resolve customer issues, provide technical assistance and resolve potential quality issues. Make the necessary changes improve the quality of your products as well as customer service, by gathering and analyzing feedback from clients.

company has high-end production equipment processing equipment, can perform high-end, custom metal processing, high-end processing, and difficult processing. We are able to process produce parts metal according customers' specifications and drawings design and can also participate in the design and development of products as well as provide OEM and ODM, have an R D facility covers more than 500 square meters, with professional R D personnel and equipment, that can collaborate in Tantalum foil and testing of products and offer a range of processing equipment to satisfy diverse customer requirements.

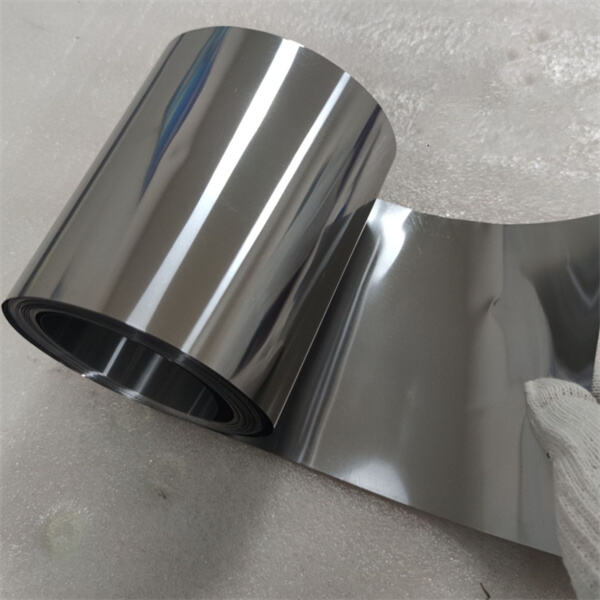

Using tantalum foil is relatively simple. The foil can be cut and shaped using standard metalworking tools, such as scissors or a razor blade. When working with tantalum foil, it is important to wear gloves and eye protection to prevent injury. TMC METAL tantalum tube can be bonded to other materials using various methods, including welding, adhesive brazing, and bonding. It can also be engraved using chemical or electrochemical etching techniques to create intricate patterns and shapes.

When purchasing tantalum foil, it is important to choose a reliable supplier that can provide high-quality products and excellent customer service. A good supplier should be able to offer technical support and advice on selecting the right type of foil to meet your specific needs. They should also offer fast delivery, competitive prices, and reliable customer support.

Tantalum foil has many applications across a wide range of industries. Some of the most common applications include:

- Electronic devices: Tantalum foil is commonly used as a capacitor material in electronic devices, such as smartphones and computers.

- Aerospace and Defense: Tantalum foil is used in a variety of aerospace and defense applications, including missile components, rocket engine parts, and shields.

- Medical Devices: Tantalum foil is biocompatible, making it suitable for use in medical implants and other medical devices.

- Chemical Handling: Tantalum foil is highly corrosion-resistant, making it ideal for use in chemical handling applications and products.

- Energy: Tantalum foil is used in a variety of energy applications, including nuclear power plants and solar panels.

Overall, tantalum foil is a versatile material with many benefits, including its high corrosion resistance, high melting point, and ductility. Advances in tantalum foil production have led to the development of ultra-thin foils and complex shapes and forms. Tantalum foil is safe and non-toxic, making it well-suited for use in a wide range of industries, including electronics, aerospace, medical, and energy. When purchasing tantalum foil, it is important to choose a reliable supplier that can provide high-quality products and excellent customer service.