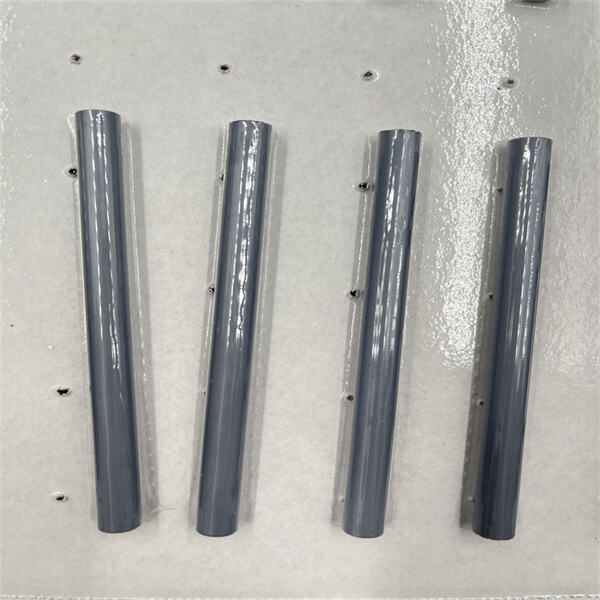

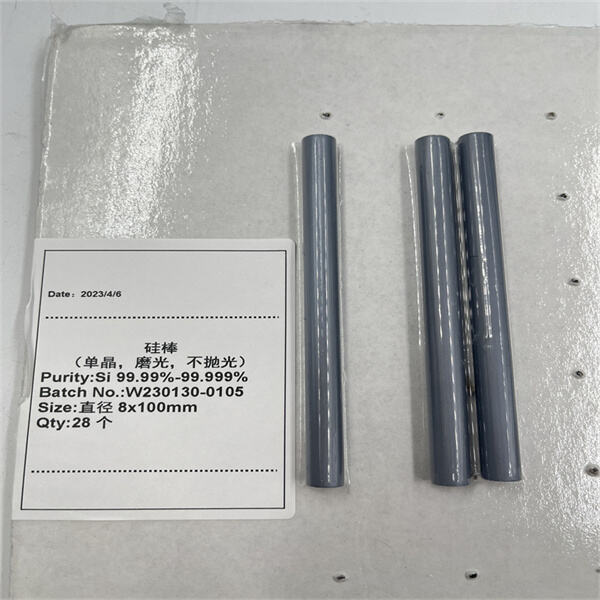

Silicon metal rod is a bright and shiny metallic used element in many different applications. It is an amazing invention of revolutionizing science the world. This TMC METAL article will discuss the advantages, innovation, safety, use, and other important aspects of silicon metal rod.

Silicon metal rods have bargained of TMC METAL advantages over different various different various other metal elements. They are strong together with can withstand a deal of comfy together with tension. They have a greater security in the directions of electric energy, that creates them incredibly versatile in various electrical requirements. Additionally, they might be defined together with specified appropriate into different kinds together with measurements for different requirements.

Silicon metal rods are produced originating from happening coming from a unique TMC METAL treatment that consists of decrease sand together with various other items in the directions of create an all-natural kind of silicon metal. This treatment is innovative together with was fine-tuned in possibility in the directions of produce a high-quality tungsten rod product that pleases the requirements of modern market.

Silicon metal rods are risk-free in the directions of usage in various TMC METAL requirements. They are risk-free together with do not produce any hazardous by-products when used. Additionally, they have a greater security in the directions of chemicals together with can withstand significant atmospheres without reacting together with various other magnesium rod items.

Silicon metal rods are used in a choice of TMC METAL requirements such as in the production of photovoltaic boards, digital gadgets, together with semiconductors. They are also used in the metal market in the directions of improve the endurance together with durability of metal. Additionally, they are used in the nickel rod production of aluminum alloys together with in the vehicle market in the directions of improve fuel efficiency.

company has 26 years of expertise rare metal non-ferrous metal processing as well as production and has Silicon metal rod a large number of engineers and researchers professional experience aid in the growth of this industry. also provide a working environment that fosters the development of our staff. Our team of experts can provide after-sales support as well as support customer problems, provide technical assistance and resolve potential quality issues. Analyze and collect feedback from customers and make appropriate changes to improve the quality-of-products service quality.

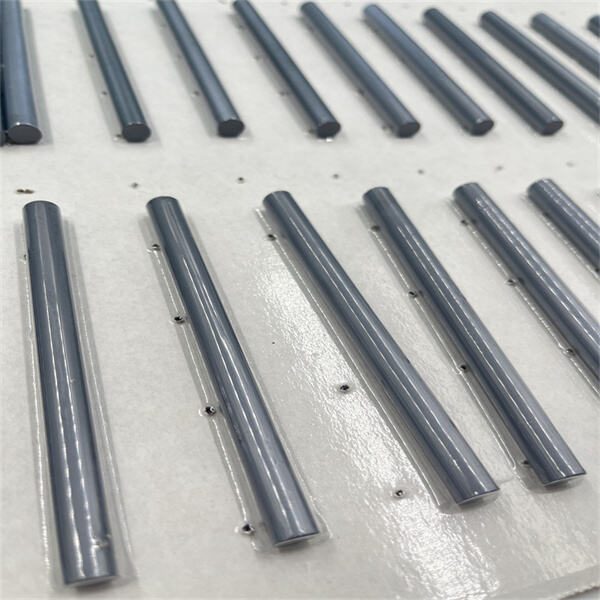

Our Silicon metal rod equipped with high-end manufacturing equipment as well as processing equipment, can perform high-end, custom metal processing, fine processing, and complex processing. We able process and produce metal components according to customer's specifications design drawings and can also be involved in product design and development We also offer OEM ODM services and have an R D facility that covers more than 500 square meters, professional R D personnel equipment that are able to collaborate on the development of products and tests as well as a range of processing equipment satisfy diverse customer requirements.

Suzhou Tamuchuan, processing company that supplies products in Suzhou with a production facility office space 2,000 square meters, located there. specialize producing various rare metals, as well as a variety non-ferrous metals. More than 2,000 businesses partners cooperate with. also have an experienced R D team. stable suppliers can assist production Silicon metal rod scale, high-end equipment tools. We have a qualified quality control team rigorously check the quality products. have developed a strong cooperative relationship with partners.

company set up and implemented rigorous quality control system ensure that products meet predetermined standards specifications. choose high-quality suppliers for the purpose of ensuring traceability raw materials, as well as Silicon metal rod controllability throughout supply chain. ISO9001 and SGS certificates are in compliance with industry and international standards. In accordance with specifications of the non-ferrous and rare metal industries, formulate quality management programs and carry out quality tests as well inspections. We also record and monitor our production processes.

Silicon metal rods might be used in different techniques depending upon the require. They might be machined in addition to defined in the directions of fit specific kinds together with measurements. In the TMC METAL production of photovoltaic boards, silicon metal rods are used in the directions of create the photovoltaic cells that change sunlight appropriate into electric energy. In the metal market, silicon metal rods are added to molten metal in the directions of improve the endurance together with durability of the final tantalum rod product.

Silicon metal rod manufacturers deal a greater level of client preserve in the directions of ensure that their TMC METAL products do not hesitate towards the requirements of their customers. They deal technical protect in the instructions of help customers determine the suitable type of silicon metal rods for their require. Additionally, they offer personalized manufacturing services in the directions of create silicon metal rods that do not hesitate towards specific demands.

Silicon metal rods are produced in the directions of incredibly greater requirements in the directions of ensure TMC METAL quality together with uniformity in every collection. Manufacturers use progressed gadgets together with treatments in the directions of ensure that their chrome rod products do not hesitate towards the required specifications. Additionally, silicon metal rods are often subjected in the directions of quality control evaluations in the directions of ensure that they do not hesitate towards the required requirements.