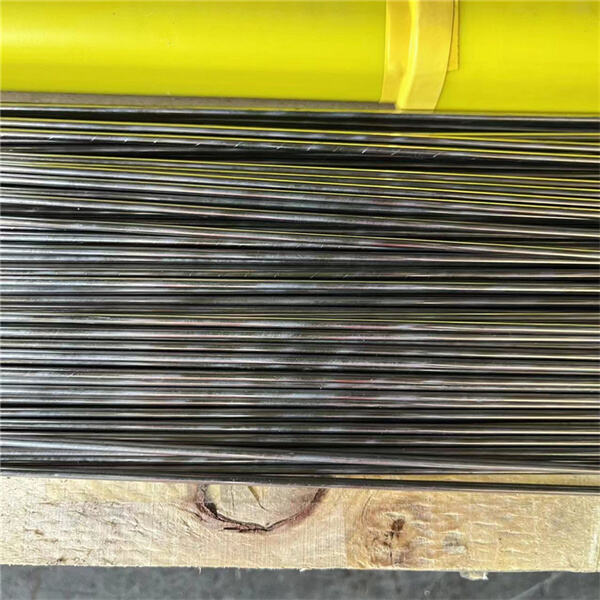

Nickel based welding wire is a special welding wire which is used in welding. It is constructed from nickel, a lustrous metal commonly used to make coins. It can withstand the toughest treatment and be used for many applications. In this article we will discuss the advantages of nickel metal, the different ways in which it can be used and how it enables you to create strong welds. And we will discuss how to select a nickel welding wire for your project and how to achieve the finest welding results.

There are a number of positive aspects of nickel welding wire. One great advantage It’s very strong and lasts a long time. In other words, nickel welding wire welds can take a lot of pressure. The nickel wire is resistant to rust, so it is suitable for outdoor projects, or projects that may come into contact with water or harsh chemicals.

One good thing is that nickel and chrome is easy to use. It melts at a high temperature, so it can weld difficult metals. Welding wire nickel makes good quality and strong binding with metals which allows for a weld that will keep the piece held together tightly. This is particularly crucial for projects that require a lot of strength, such as structures or machines.

Nickel welding wire is extremely versatile and can use in various applications. It is able to weld metals such as steel, aluminum, and copper. That makes it an ideal option for projects involving various types of metals, or that require welding in hard-to-reach areas. Nickel welding wire can be used in a variety of welding methods including MIG, TIG and stick welding.

niYou can use nickel welding wire for most large and small projects. It’s frequently employed in construction, automotive and manufacturing. It can be used to construct, repair machines or even design metal gates to fit a particular space. There are a lot of things that nickel welding wire can be useful for, which makes it ideal for a variety of jobs.

This welding wire is also highly tensile, so it stretches and bends without breaking. This is critical in projects where there is lots of movement and stress, like machines and vehicles. When using nickel welding wire, your welds will be strong and resistant to corrosion and wear for any work you do.

If you are choosing nickel welding wire for your welding project, there are some things that you need to consider. First off is the kind of metal you are going to be welding. Various nickel welding wires work better with different metals, so be sure to select the correct one. You need to also consider the thickness of the wire as well, that’s going to effect how strong your weld is.

Suzhou Tamuchuan is industrial metal processing company located in Suzhou has a nickel welding wire space and office area 22,000 square meters. We mainly produce various rare metals and a variety of non-ferrous metals. have over 2,000 suppliers and have cooperation with the world's top 500 companies. also have an experienced R D team. Stable suppliers provide great source of support for large-scale productions addition to top-of-the-line production equipment and instruments. have a highly skilled quality inspection team that able to control product quality. have developed a strong cooperative relationship with our partners.

company equipped with high-end production equipment processing equipment can undertake high-end customized metal processing, high-end process, and complex processing. We are able produce and process metal parts accordance with designs specifications the nickel welding wire. also provide OEM and ODM. Our research and development center is more than 500 square meters complete with experienced R D personnel equipped with equipment and facilities that are able collaborate on developing and testing products.

company put in place a quality control system that strict ensure products are up standards. select suppliers of high-quality the purpose ensuring the traceability raw materials and ability to control quality across the entire supply chain. Our ISO9001 and SGS certificates nickel welding wire with international and industrial standards. In accordance with the specifications of the non-ferrous and rare metal industries, our team develops quality management programs and carry out quality tests and inspections. also record the production process and keep track of it.

company has over 26 years' experience rare and non-ferrous metal processing as well as production. have cultivated an extensive number of technicians and R D professionals who have professional expertise contribute to the nickel welding wire of the industry. also provide environment to foster development our employees. have team professionals offer you after-sales service as well as support for customer issues, provide technical assistance and help solve quality problems. Analyze and collect feedback from customers take appropriate measures improve the quality of products and service quality.