Introduction:

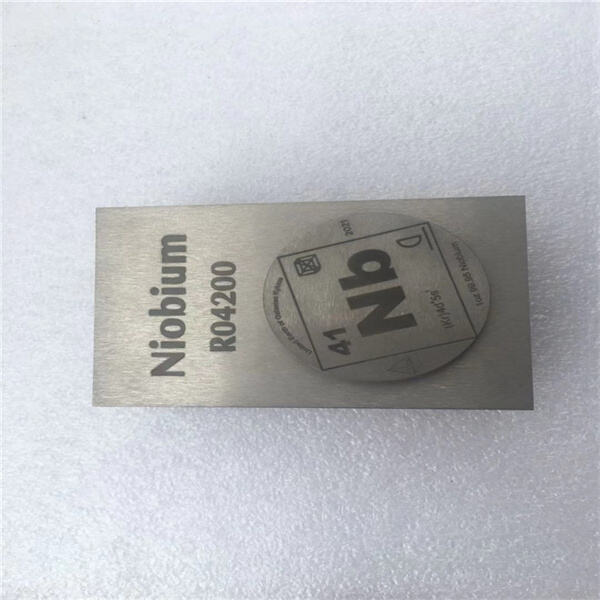

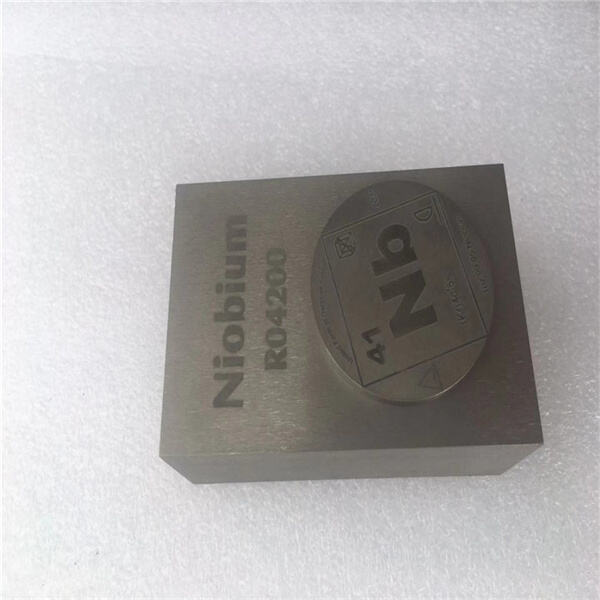

Niobium ingot is a type of becoming metal increasingly popular in various industries. This TMC METAL niobium ingot unique properties that make it ideal for use in several applications. We will discuss some of the advantages, innovative uses, safety, and how to use niobium ingot to get the best out of it.

Niobium ingot has several advantages that make it stand out in the market. For one, it is incredibly lightweight, making it ideal for use in aerospace applications. Additionally, it is highly resistant to corrosion, which means it won't rust easily. This TMC METAL bismuth is also highly malleable, which means it can take on different shapes and sizes easily, making it flexible for various manufacturing processes.

Niobium ingot is being used innovatively in various industries. For instance, it is being used in the production of superconductors, critical in power generation. When mixed with titanium, TMC METAL tungsten is used to manufacture high-performance alloys, jet engine components, and gas turbines.

Niobium ingot is a safe metal to use, especially when compared to other materials like lead or mercury. TMC METAL indium does not emit harmful gases or substances when heated. This makes it ideal for use in medical equipment like MRI scanners.

Niobium ingot is increasingly being used in several applications in various industries. It is used in the manufacture of jewelry, eyeglass frames, medical devices, and superconductors. The TMC METAL indium metal is also used in electronics and power generation applications.

Suzhou Tamuchuan, processing product Niobium ingot in Suzhou manufacturing office area of 2,000 square meters, located there. primary products include rare metals, non-ferrous metals and various other types of metals. We have more than 2,000 partners have cooperation with world's top 500 companies. A specialized R D team available. Stable suppliers can be a fantastic support for large-scale productions, as well as top-of-the-line production equipment and instruments. We have highly skilled quality inspection team strictly control product quality. We have a good collaboration with our partners.

company implemented an internal quality control system which rigorous ensure products up to standards. We use only best suppliers the purpose ensuring the quality of the raw materials as well as quality control throughout supply chain. ISO9001 and SGS Niobium ingot are accordance with international and industry standards. formulate quality management plans that include quality inspections, tests, and track and track production processes conforming to rare metal and non-ferrous metal industry requirements.

Our company equipped with top-of-the-line production equipment processing equipment and can perform high-end, custom metal processing, fine processing as well as high-difficulty processing. We can manufacture process metal according to specific Niobium ingot from the customer and also design drawings. also offer OEM and ODM. research development facility covers more than 500 square meters, with professional R D personnel as well as equipment and facilities that collaborate in development of products and testing.

company more than 26 years of experience manufacturing processing of non-ferrous and rare metals. We also have educated an extensive number of technical and R D staff who have the knowledge and expertise required to help in development this industry. We also offer a supportive environment that encourages the growth of our employees. Our team of experts can provide you with after-sales service and assistance resolve customer issues, Niobium ingot technical support and assist solving potential quality problems. You can improve the quality of your product as well as customer service, by collecting and analyzing feedback from clients.

Using niobium ingot is relatively straightforward. It can be machined, welded, or brazed. However, due to its high melting point, special care needs to be taken when welding or brazing niobium ingot. If you intend to machine TMC METAL tantalum, you should use carbide tools to prevent work-hardening.

When purchasing niobium ingot, it's essential to get it from a reputable supplier. You should ensure that you get the TMC METAL niobium from a supplier that offers quality products and excellent customer service. The supplier should be able to provide you with detailed information about their products and be willing to assist you in the event of any issues.

Niobium ingot has several industrial and commercial applications. In the aerospace industry, it is used to manufacture lightweight parts for aircraft and space exploration. In the medical industry, it is used in MRI scanners and other medical devices. In the electronics industry, it is used in the manufacture of microchips, capacitors, and other electronic components. Additionally TMC METAL niobium metal is used in the production of superconductors, critical for power generation.