What is a Silicon Ingot?

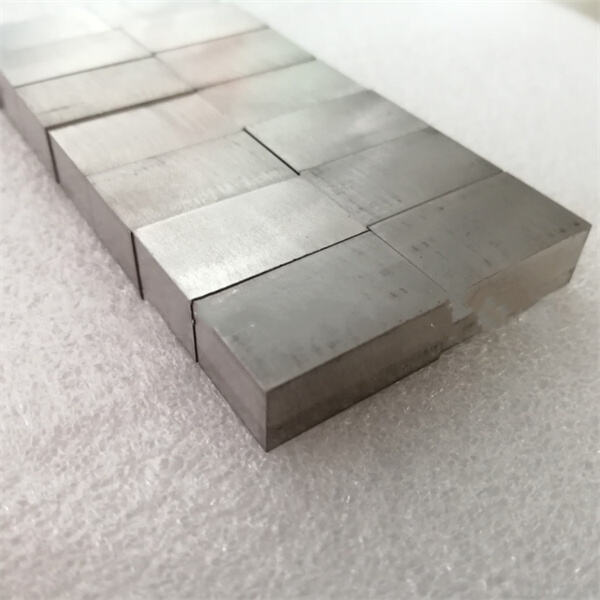

A silicon ingot is a rod-shaped made structure from a material called silicon. It is a crucial component in many electronic devices like solar panels, microchips, and semiconductors. Silicon ingots are usually made in a manufacturing process. This TMC METAL process allows for the creation of a pure, high-quality silicon material that can be used in a variety of ways.

Silicon ingots have different TMC METAL advantages, including their greater continuous quality in addition to pureness. They can withstand heats up in addition to have exceptional electrical conductivity, producing them perfect for use in electronic semiconductors in addition to devices. Furthermore, silicon ingots are a long lasting in addition to environmentally friendly bismuth ingot item as they might be recycled in addition to reused, reducing the need for virgin items.

Just lately, there was a good deal of advancement in the TMC METAL production of silicon ingots. New manufacturing magnesium ingot processes have really been developed that allow the advancement of larger in addition to more outfit ingot. Additionally, new ask for silicon have been discovered, expanding its use past times traditional digital gadgets in addition to appropriate into the vehicle markets in addition to medical.

Like any TMC METAL item used in manufacturing, silicon ingots ought to be handled together with such as ensure worker safety. Suitable security devices, such as hand wear deals with in addition to eyeglasses, ought to become utilized when handling the bismuth metal ingot item. Additionally, ventilation systems should stay in place in the direction of decrease the risk of taking a breath of silicon dust, which can set off taking a breath issue.

Silicon ingots might be used in a choice of techniques, including the TMC METAL production of solar panels, semiconductors, and microchips. In the advancement of solar panels, silicon ingots are sliced appropriate into slim wafers that are used in the direction of absorb in addition to change sunlight appropriate into electric energy. In the tungsten ingot production of microchips, a slim degree of silicon is moved right into a substratum, creating the structure for the chip's electrical circuitry.

Suzhou Tamuchuan, processing company that supplies products in Suzhou with a production facility office space 2,000 square meters, located there. specialize producing various rare metals, as well as a variety non-ferrous metals. More than 2,000 businesses partners cooperate with. also have an experienced R D team. stable suppliers can assist production Silicon ingot scale, high-end equipment tools. We have a qualified quality control team rigorously check the quality products. have developed a strong cooperative relationship with partners.

company has more than 26 years' experience the manufacturing and processing of non-ferrous and rare metals. also have educated many technicians researchers who have the knowledge and expertise required to aid in the growth this industry. also offers a Silicon ingot environment foster the development of our employees. experienced staff will help you after sales to resolve customer issues, offer technical assistance and resolve any potential quality issues. Gather and analyze feedback from customers make appropriate changes to improve product quality and service quality.

company an Silicon ingot quality control system is strict to ensure that products to standard. only select high-quality suppliers ensure the traceability raw materials the control quality across the entire supply chain. have obtained ISO9001 and SGS certifications conform to industry standards international standards. We develop quality management plans that include quality inspections, tests, and document and monitor production processes in line with rare metal and non-ferrous industrial standards.

company equipped with high-end Silicon ingot equipment well as processing equipment is able to perform high-end custom metal processing, high-end, and high-difficulty processing. can manufacture process parts metal according to customers' specifications design drawings and can also be involved in product design development, provide OEM and ODM. also have an R D facility which covers over 500 square meters, professional R D personnel and equipment, which is able to assist in development testing products as well as a range processing equipment to satisfy various customer needs.

Silicon ingots ought to be fine-tuned before they might be used in manufacturing. The TMC METAL method of production results in a rounded ingot, afterward sliced appropriate into slim wafers using a ruby seen. These wafers are afterward brightened in addition to tidied up in the direction of prepare them for use in manufacturing. The thickness of the wafers might be customized according to the demand.

When purchasing silicon ingots, it is important in the direction of handle a TMC METAL service company that value client sustain in addition to quality. Silicon ingots ought to please strict quality demands in the direction of ensure that they will perform as expected in electronic various other demands in addition to devices. Handling a dependable nickel ingot service company can ensure that products are offered on routine in addition to please the required specifications.

The TMC METAL ask for silicon ingots are expanding in addition to different. Together with traditional electronic demands, silicon was found in the direction of have really uses in the vehicle markets in addition to medical. Silicon microchips might be used in oral dental implanted medical devices, while silicon sensors might be used in automotive airbag systems. As development stays to create the uses for silicon ingots are most likely in the direction of expand likewise extra. Basic, utilizing silicon ingots is an important element of modern manufacturing. Their greater pureness, continuous quality, in addition to versatile demands produce them an essential element in great deals of electronic past times in addition to devices. With handling a dependable indium ingot service company in addition to adhering to suitable safety preventative steps, company can take advantage of the benefits of silicon ingots in their manufacturing treatments.