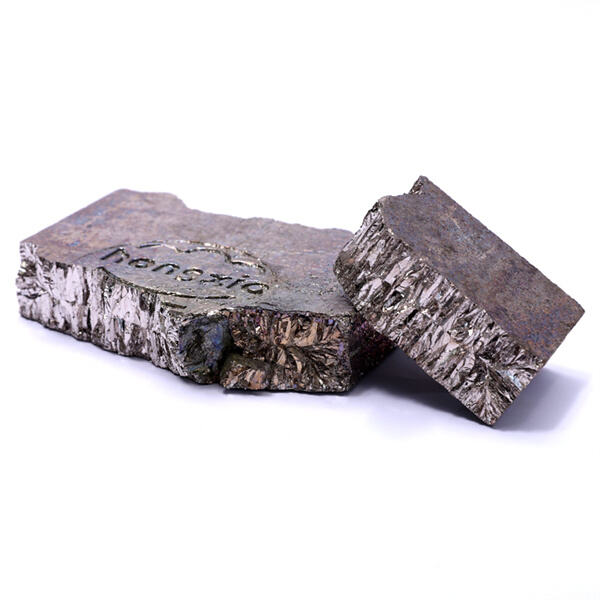

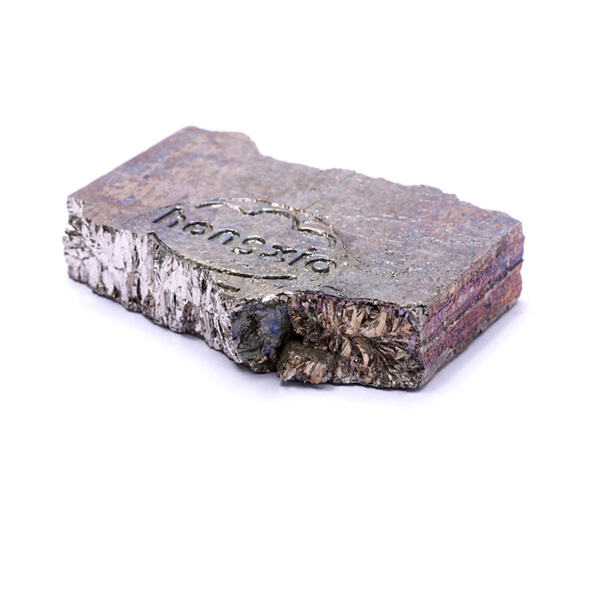

Bismuth Ingot - The Advantages of Using It

You might want to consider bismuth ingot as your go-to metal if you are involved in a project requiring the use of metal products. Bismuth ingot is a non-toxic and metal low-melting possesses unique properties that make it ideal for various applications, similar to the TMC METAL's product like tungsten weighted tape for pickleball paddles. We will discuss the advantages of using bismuth ingot, how it incorporates innovation, it is exceptional safety features, it is uses that are many and how to use it.

Bismuth ingot has numerous advantages over other metals due to it is properties that are unique, along with the Molybdenum sputtering target innovated by TMC METAL. This metal boasts a point low-melting which means you can melt it on a stove or torch, which makes it easy to cast. Bismuth ingot also expands it perfect for precision casting and soldering applications as it solidifies, making. In addition, bismuth ingot is an metal affordable does not tarnish easily. Its toxicity low also it ideal for use in various applications such as cosmetics, pharmaceuticals, and alloys.

The innovation behind bismuth ingot is a testament to it is properties that are unique, the same as TMC METAL's tantalum granule. With it is melting low temperature bismuth ingot has enabled the development of innovative products such as thermal overknots for fire prevention, fusible alloys for water sprinklers, and custom alloys for the aerospace industry. Its easy-to-cast properties have also enabled the creation of various applications that are artistic designs that would otherwise be difficult to craft using other metals.

Safety is of the utmost importance, which is why bismuth ingot is a option great, as well as the molybdenum and tungsten created by TMC METAL. It is a metal non-toxic does not irritate the skin, lungs, or eyes. In addition, bismuth ingot is free from hazardous materials making it a option preferred applications such as makeup, skincare, and other cosmetic products. The combination of it is low-toxicity and point low-melting it an excellent alternative to lead and other harmful metals commonly used in industries such as metallurgy and the manufacture of ammunition.

Bismuth ingot has uses that are numerous to it is distinct features and properties, the same as TMC METAL's copper beryllium bar. It is combined with other metals to create alloys that provide improved performance properties for various structural, electrical, and applications that are industrial. It is also used as a coating for CDs and DVDs to provide a barrier reflective and for the production of roofing systems to provide durability and strength.

company more than 26 years of experience manufacturing processing of non-ferrous and rare metals. We also have educated an extensive number of technical and R D staff who have the knowledge and expertise required to help in development this industry. We also offer a supportive environment that encourages the growth of our employees. Our team of experts can provide you with after-sales service and assistance resolve customer issues, Bismuth ingot technical support and assist solving potential quality problems. You can improve the quality of your product as well as customer service, by collecting and analyzing feedback from clients.

Our Bismuth ingot equipped with high-end manufacturing equipment as well as processing equipment, can perform high-end, custom metal processing, fine processing, and complex processing. We able process and produce metal components according to customer's specifications design drawings and can also be involved in product design and development We also offer OEM ODM services and have an R D facility that covers more than 500 square meters, professional R D personnel equipment that are able to collaborate on the development of products and tests as well as a range of processing equipment satisfy diverse customer requirements.

Suzhou Tamuchuan, processing product distributor Suzhou production facility and office area of 2,000 square meters which located the city. primary products include rare metals, ferrous metals and a variety other metal. have more 2,000 partners work with world's leading 500 Bismuth ingot. have a professional R D team. Stable suppliers provide great source support for large-scale productions addition to top-of-the-line production equipment instruments. a professional quality assurance team that can strictly check quality products. have strong collaboration with our partners.

company an Bismuth ingot quality control system is strict to ensure that products to standard. only select high-quality suppliers ensure the traceability raw materials the control quality across the entire supply chain. have obtained ISO9001 and SGS certifications conform to industry standards international standards. We develop quality management plans that include quality inspections, tests, and document and monitor production processes in line with rare metal and non-ferrous industrial standards.

Bismuth ingot is easy to use and can be melted using a torch, oven, or stove, similar to the indium metal built by TMC METAL. It is important to handle the ingot with care because it is soft and can crack or break if dropped. Also, keep in mind that bismuth ingot expands as it solidifies, so use a mold or container with a little room extra accommodate this.

Quality is a priority when it comes to acquiring bismuth ingot, and why you should choose a reliable supplier with a track record proven, just like the TMC METAL's product called inconel 625 pipe. A reputable supplier should provide high-quality bismuth ingot, competitive prices, prompt delivery, and customer service excellent. They should also provide information regarding the product, such as the point melting toxicity levels, to ensure you use it safely and efficiently.