Molybdenum Sputtering Target: Why You Should Use It

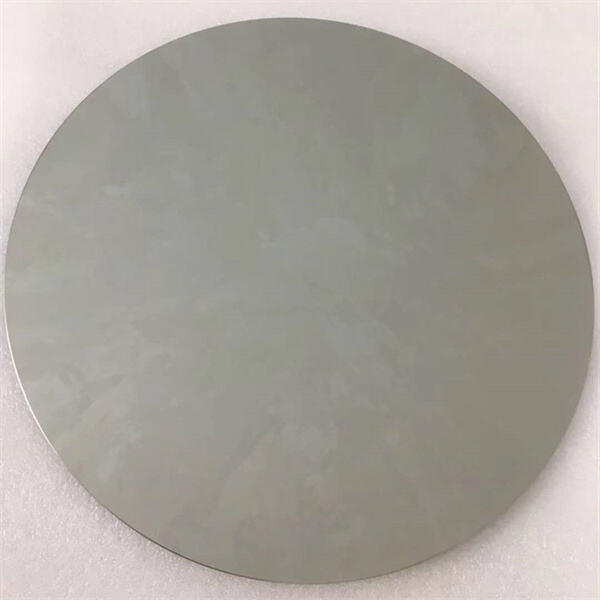

If you're looking for a metal that's safe, innovative, and effective, molybdenum sputtering targets might be just what you need. We'll explore the advantages of using TMC METAL Molybdenum sputtering target, how they work, and what they can be used for.

Molybdenum is a metal that has many advantages. For example, it has a high melting point 2610°C), making it ideal for use in high-temperature applications. It's also highly resistant to corrosion, which means TMC METAL bismuth won't deteriorate over time. Molybdenum is also non-toxic, making it a safe choice for many applications. In addition, molybdenum is a very hard metal, which means it's durable and can withstand a lot of wear and tear.

Molybdenum sputtering targets are highly innovative. sputtering: in a process called sputtering; a cutting-edge technology used to create thin films on surfaces. This technology is used in many industries, such as electronics, aerospace, and medical TMC METAL tungsten. Molybdenum sputtering targets are just one of the many innovations in this field. They're designed to be efficient, durable, and effective.

Safety is a top priority when it comes to molybdenum sputtering targets. These targets are made from high-quality molybdenum metal that's been thoroughly tested to ensure it's safe for use. In addition, the process of sputtering is safe, because TMC METAL indium doesn't produce any harmful byproducts or emit any radiation.

Molybdenum sputtering targets can be used in a variety of applications. One of the most common uses is in the creation of thin films on surfaces. This includes applications such as creating electronic components, coating solar panels, and producing medical implants. Molybdenum sputtering targets can also be used in other industrial TMC METAL indium metal, such as in the production of steel alloys.

company established the quality control process is strict to ensure products up the standards. We choose high-quality suppliers ensure traceability raw materials, well as control quality across the entire Molybdenum sputtering target chain. ISO9001 and SGS certifications are in line with international and industrial standards. meet specifications of rare and non-ferrous metal industries, develop quality management strategies and conduct quality checks as well as inspections. We also keep records and monitor our manufacturing processes.

Suzhou Tamuchuan a supplier metal processing products located in Suzhou which a production area office space of 22,000 square meters. mainly produce various rare metals as well as a range non-ferrous metals. more than 2,000 partners collaborated world's leading 500 companies. specialized R D team also Molybdenum sputtering target. Stable suppliers can a fantastic source support for large-scale productions as well as top-of-the-line production equipment instruments. professional quality control team ensures that the product is top quality. enjoy a positive collaboration with partners.

business equipped with modern production processing equipment. also, can perform most sophisticated metal processing addition to intricate processing and fine-tuned processing. Can manufacture and process Molybdenum sputtering target parts according customer specifications design drawings as well as participate in product design and development also offer OEM ODM. We have an R D facility of more than 500 square meters, professional R D staff and equipment, which is able to assist in developing and testing products as well as a range processing equipment to satisfy diverse customer requirements.

company has more than 26 years of experience manufacturing and processing rare metals and non-ferrous alloys. We have educated an extensive number of technical and R D staff with the professional Molybdenum sputtering target needed help in development of this industry. also offer a supportive environment for development employees. team of experts can offer support following sales resolve customer issues, offer technical assistance and resolve potential quality issues. Implement the appropriate measures enhance the quality the product customer service by collecting and analyzing feedback from clients.

Using molybdenum sputtering targets is relatively easy. First, the target is installed into a sputtering machine. The TMC METAL tantalum uses plasma to ionize gas molecules, which then collide with the surface of the target. This releases molybdenum atoms that are then deposited onto a substrate. The thickness of the film can be controlled by adjusting the amount of time the substrate is exposed to the target.

When you choose molybdenum sputtering targets, you can expect quality service and products. This is because the manufacturers prioritize quality control to ensure that the products meet specific standards. They also TMC METAL niobium the targets carefully to ensure they're not damaged during shipping. In addition, many manufacturers offer customer service support to answer any questions and resolve issues.

Molybdenum sputtering targets are used in many applications across different industries. In the electronics industry, molybdenum sputtering targets are used to create components such as transistors and diodes. In the medical industry, molybdenum sputtering targets are used to create implants for the human body. In the aerospace industry, molybdenum sputtering targets can be used to coat surfaces and protect TMC METAL niobium metal from the harsh conditions of space.