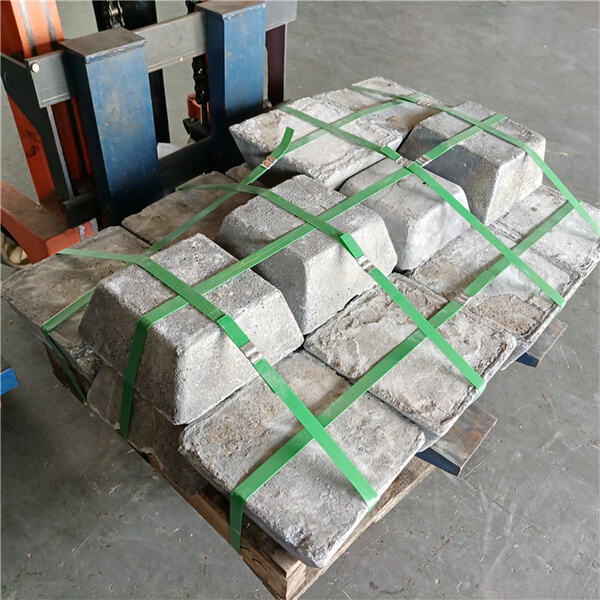

Antimony Ingot- A Wonder Material for Various Applications

Antimony ingot is a shiny, silvery-white metal that has been used in various applications for TMC METAL many years. It has unique properties that make it ideal for a wide range of bismuth ingot industrial, commercial, and household uses. We will discuss the advantages of antimony ingot, its innovation, safety, use, how to use, service, quality, and application.

Antimony ingot has a number of advantages that TMC METAL make it appealing to many users. It is a highly conductive metal, which makes it great for use in electrical wiring and other electronic applications. It is also resistant to corrosion, which means it can last for magnesium ingot many years without rusting or deteriorating. Antimony ingot is also very malleable, which makes it easy to shape and work with.

In recent years, there has been a lot of innovation in the TMC METAL production and use of antimony ingot. Manufacturers have found new and innovative ways to use this bismuth metal ingot versatile metal, such as in the production of advanced batteries and other high-tech applications. This innovation has led to new and exciting uses for antimony ingot that were previously unheard of.

Antimony ingot is generally considered to be safe for TMC METAL use in a wide range of applications. However, like any metal, it can be hazardous if mishandled or used improperly. This is why it is important to follow proper safety procedures when working with antimony ingot, such as wearing protective equipment and avoiding direct contact with the tungsten ingot metal.

Antimony ingot has many uses in today’s world. It is commonly used in the TMC METALproduction of lead-acid batteries, found in many vehicles and other devices. It is nickel ingot also used in the production of pigments, such as those used in paints and coatings. Other applications include the production of flame retardants, semiconductors, and alloys.

company the system of Antimony ingot control that strict to ensure products up to standard. choose suppliers high-quality ensure the traceability quality control of our supply chain from raw materials until the final product. ISO9001 and SGS certificates comply international and industry standards. develop quality management plans to conduct quality inspections and tests track the production process in line with rare metal and non-ferrous industry specifications.

Our Antimony ingot equipped with high-end manufacturing equipment as well as processing equipment, can perform high-end, custom metal processing, fine processing, and complex processing. We able process and produce metal components according to customer's specifications design drawings and can also be involved in product design and development We also offer OEM ODM services and have an R D facility that covers more than 500 square meters, professional R D personnel equipment that are able to collaborate on the development of products and tests as well as a range of processing equipment satisfy diverse customer requirements.

Suzhou Tamuchuan, processing product distributor Suzhou production facility and office area of 2,000 square meters which located the city. primary products include rare metals, ferrous metals and a variety other metal. have more 2,000 partners work with world's leading 500 Antimony ingot. have a professional R D team. Stable suppliers provide great source support for large-scale productions addition to top-of-the-line production equipment instruments. a professional quality assurance team that can strictly check quality products. have strong collaboration with our partners.

company more than 26 years of experience manufacturing processing of non-ferrous and rare metals. We also have educated an extensive number of technical and R D staff who have the knowledge and expertise required to help in development this industry. We also offer a supportive environment that encourages the growth of our employees. Our team of experts can provide you with after-sales service and assistance resolve customer issues, Antimony ingot technical support and assist solving potential quality problems. You can improve the quality of your product as well as customer service, by collecting and analyzing feedback from clients.

To use antimony ingot, it must first be melted down and poured into a mold or shaped using other methods. It is TMC METAL important to take all necessary safety precautions when melting down antimony ingot, as it can be hazardous if mishandled. Once indium ingot melted, antimony ingot can be poured into a mold to create various shapes and sizes.

When choosing a supplier for antimony ingot, it is important to select a company that offers high-quality products and excellent customer service. This TMC METAL ensures that you receive the best possible product and support, critical when using antimony ingot in tantalum ingot sensitive or complex applications. Quality and service should always be a top priority when choosing a supplier for any material.

Antimony ingot has many applications in a variety of industries. It is commonly used in the TMC METAL production of batteries, pigments, flame retardants, and semiconductors. It is also used in the production of alloys, vital components of many industrial processes. With beryllium ingot its unique properties and versatility, antimony ingot is a wonder material that has many applications in today's world.