Hafnium wire is a kind of significant helium spare material which is applied in modern industries. It’s durable and heat-resistant, which is why many industries use it. Now, we will know about the special features of Hafnium particles and its application.

Today hafnium wire is employed widely in various technologies owing to its unique properties. Strong and able to withstand high temperatures, it’s a popular choice for industrial purposes. Hafnium wire, on account of its high melting point and good conductivity, is utilized in the aerospace industry, electronics, and nuclear reactors.

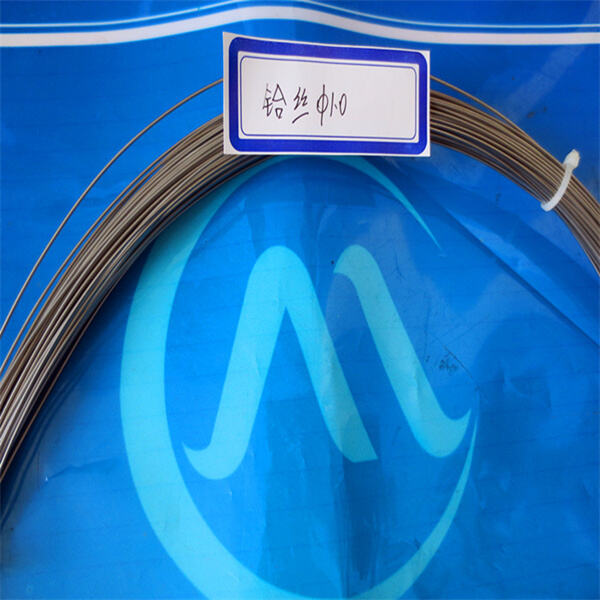

Hafnium wire is a tough, heat-resistant type of wire. It can support high temperatures without becoming weak, which is why it is used in manufacturing processes that require high heat. Hafnium wire is highly resistant to impact and damage, making it highly valued in industries such as aerospace, automotive and electronics.

In the aerospace market, hafnium wire is sought after for a variety of reasons, due to its unique characteristics. It is light, and can withstand high heat, which is great for aircraft parts. Corrosion resistant: Hafnium wire is also resistant to corrosion, for long-lasting performance -Ideal for challenging outdoor settings. For this reason, its thermal conductivity is perfect for heat exchangers and other cooling systems in aerospace technology.

Hafnium wire, due to its excellent absorption of thermal neutrons, has an especially important use in nuclear reactors. It’s also mixed into control rods to help control how quickly nuclear reactions unfold. Hafnium wire is used to ensure that nuclear reactors stay safe and steady. Accordingly it is a sought-after material in the nuclear industry.

But as more people desire electronic devices, hafnium wire has become a metal of choice for manufacturers. It melts at a high temperature and is an excellent electrical conductor. Hafnium wire is used in electronic components such as capacitors, resistors and transistors for the same reason it performs so impressively in the NIF: It is predictable. It is also used in the production of semiconductors; it is good at conducting electricity. The use of hafnium wire can be expected to grow with the increasing popularity of electronic devices.

Our company equipped with top-of-the-line production equipment processing equipment and can perform high-end, custom metal processing, fine processing as well as high-difficulty processing. We can manufacture process metal according to specific hafnium wire from the customer and also design drawings. also offer OEM and ODM. research development facility covers more than 500 square meters, with professional R D personnel as well as equipment and facilities that collaborate in development of products and testing.

company established the quality control process is strict to ensure products up the standards. We choose high-quality suppliers ensure traceability raw materials, well as control quality across the entire hafnium wire chain. ISO9001 and SGS certifications are in line with international and industrial standards. meet specifications of rare and non-ferrous metal industries, develop quality management strategies and conduct quality checks as well as inspections. We also keep records and monitor our manufacturing processes.

Suzhou Tamuchuan, processing company that supplies products in Suzhou with a production facility office space 2,000 square meters, located there. specialize producing various rare metals, as well as a variety non-ferrous metals. More than 2,000 businesses partners cooperate with. also have an experienced R D team. stable suppliers can assist production hafnium wire scale, high-end equipment tools. We have a qualified quality control team rigorously check the quality products. have developed a strong cooperative relationship with partners.

company has 26 years of expertise rare metal non-ferrous metal processing as well as production and has hafnium wire a large number of engineers and researchers professional experience aid in the growth of this industry. also provide a working environment that fosters the development of our staff. Our team of experts can provide after-sales support as well as support customer problems, provide technical assistance and resolve potential quality issues. Analyze and collect feedback from customers and make appropriate changes to improve the quality-of-products service quality.