Tungsten copper rods are very useful in the industry. They’re employed in all sorts of ways to help make things work better. Well today we’re going to learn all about tungsten copper rods, how they are manufactured and why they are so unique.

They are of extremely high quality and strength and are often used in industrial applications. They are heat and pollution resistant, suitable for harsh environments. These rods also transmit electricity very well, and that's crucial for many industrial applications. With tungsten copper rods, industries can carry on with their operations without worrying for their equipment.

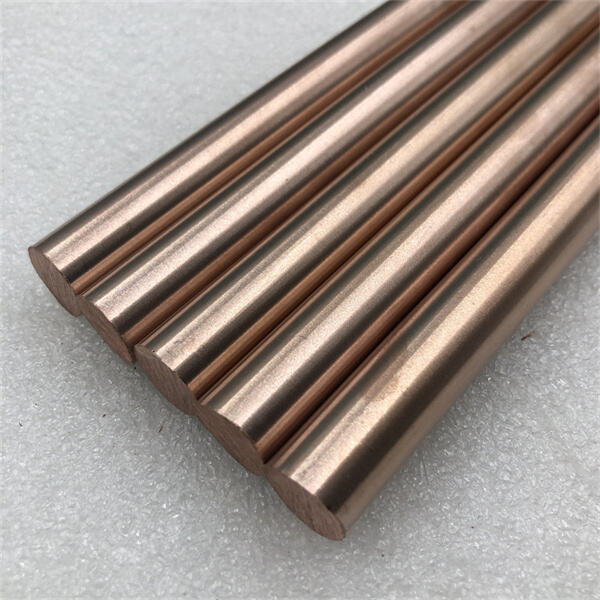

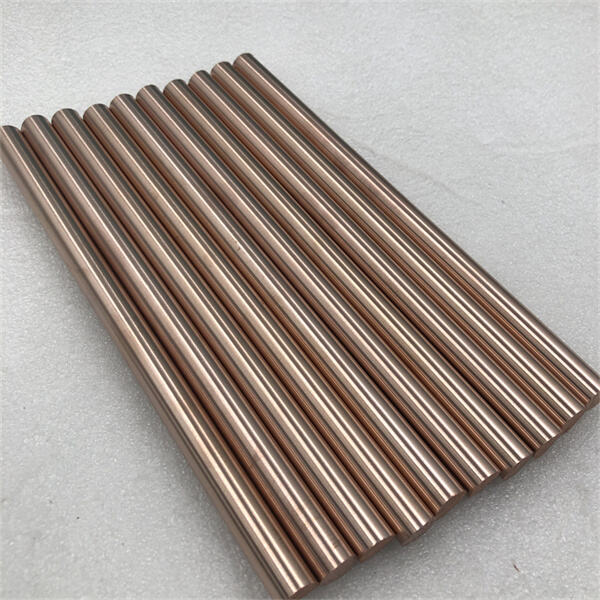

Tungsten copper rods are fabricated by blending tungsten and copper metals. Smelt the metals and mix together to form a strong and durable rod. This is done in specialized factories that have the proper equipment for working with these metals. After the rods are manufactured, they are tested to ensure they meet stringent performance criteria. Tungsten copper rod are precision forged from the high purity tungsten and oxygen free copper, which can be applied in different fields.

Tungsten copper rods With characteristics of high thermal conductivity and electrical conductivity. They are excellent conductors of electricity, which is crucial for electronic devices to work well. These rods are also utilized for electronic heat sinks to cool down circuits and evacuate heat. Tungsten copper bars are found in the computers we work on, cell phones we own and other electronic goods we use on a daily basis. Our electronics wouldn’t be half of what they are without these rods.

The tungsten copper bar offers one of the best heat dissipation properties. Electronic devices can heat up when in use. Tungsten copper rods aid in extracting the heat away from the components to avoid getting hot and damaged. This is especially true in devices that you use for extended periods, such as your computer and smartphone. Material: Copper Tungsten Copper Tungsten rods are, due to the high temperature stability, used in spark erosion processes and other high temperature applications, where it performs well.

Selecting the Right Tungsten Copper Rod for the Job When selecting a tungsten copper rod for your project, you should always take into account the requirements of your job. Rods can have different properties and so it is important to select a rod that takes job activity into account. TMC METAL provides a variety of quality Tungsten Copper Rods for outstanding performance and consistent service life. You can make absolutely certain your equipment will work as expected and maximally with one of the right rods for the job.

company has developed implemented stringent quality control process ensure that the products offer meet specified standards and specifications. We choose suppliers of high-quality ensure the ability trace and control quality of our supply chain runs from raw materials through to final products. have passed ISO9001 as well as SGS certifications that tungsten copper rod with industry and international standards. We develop quality management plans that include quality inspections, tests, and track and track manufacturing processes in accordance with rare metal and non-ferrous industry specifications.

Suzhou Tamuchuan, processing product tungsten copper rod in Suzhou manufacturing office area of 2,000 square meters, located there. primary products include rare metals, non-ferrous metals and various other types of metals. We have more than 2,000 partners have cooperation with world's top 500 companies. A specialized R D team available. Stable suppliers can be a fantastic support for large-scale productions, as well as top-of-the-line production equipment and instruments. We have highly skilled quality inspection team strictly control product quality. We have a good collaboration with our partners.

company equipped with top-of-the-line production equipment processing equipment can undertake high-end customized metal processing, fine process, and high-difficulty processing. We able produce process metal parts designs and specifications of customer. also tungsten copper rod OEM and ODM. Our research and development center larger than 500 square meters that is staffed professional R D personnel, equipment and facilities can work together in the development of products and testing.

company has over 26 years' experience rare and non-ferrous metal processing as well as production. have cultivated an extensive number of technicians and R D professionals who have professional expertise contribute to the tungsten copper rod of the industry. also provide environment to foster development our employees. have team professionals offer you after-sales service as well as support for customer issues, provide technical assistance and help solve quality problems. Analyze and collect feedback from customers take appropriate measures improve the quality of products and service quality.