サブ見出し: はじめに

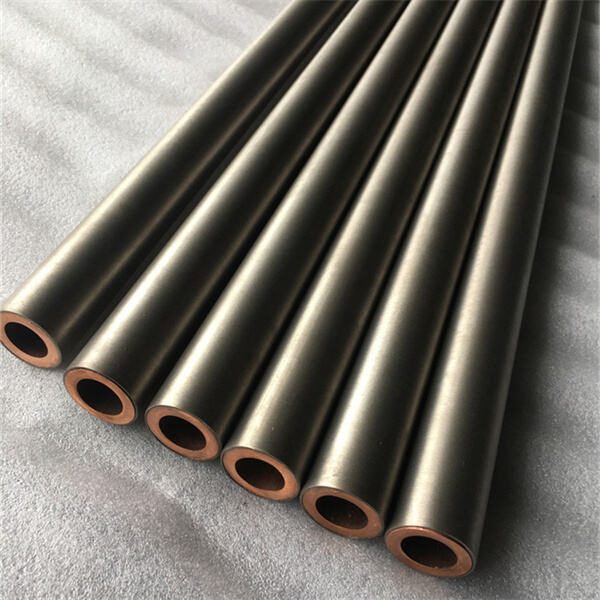

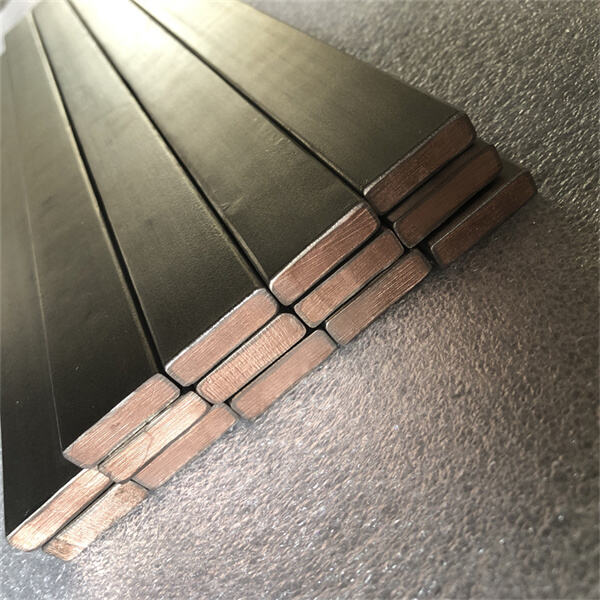

チタンクラッド銅は実際に市場に導入された革新的な新製品であり、一般公众から大きな注目を集めています。この製品は、チタンと銅という2つの金属を組み合わせて作られ、真実で有用な金属構成を持っています。

近年、チタンクラッド銅は多くの業界で好まれる選択肢となっている特性があり、非常に人気になっています。このTMC METAL チタン被覆銅 マーケティング記事は、チタンクラッド銅の利点、革新性、安全性、使用法、サービス、品質について強調することを目的としています。

クラッド銅の利点は、チタンの能力と耐食性を銅の優れた伝導性と組み合わせているという事実です。この組み合わせは製品の耐久性を高めるユニークなものです。これにより、過酷な環境での使用に非常に適しています。さらに、TMC METAL ニオブ チタン合金 純粋な銅が高すぎてうまく扱うことができない経済的な状況においても、解決策を提供します。耐久性和コストパフォーマンスだけでなく、クラッド銅は腐食にもかなり強いです。これは、多くの腐食性物質(酸、アルカリ、塩水など)に接触しても耐えられるため、危険な環境での使用に適していることを意味します。

チタン被覆銅の開発は、製造業での使用方法を革命的に変えた開発であると言えます。この方法は完全に新しいもので、製造プロセスにおける純チタンと銅の標準的な使用方法を置き換え、それをより安全で効率的なものにしました。また、TMC METALも関連しています。 ニッケルおよびチタン合金 輸送産業におけるその使用は安全性を向上させました。この製品の強度と耐久性は、事故や問題を引き起こすリスクを大幅に低減します。

チタン被覆銅は非常に汎用性が高く、製造、輸送、航空宇宙などのさまざまな産業で応用されています。その耐久性、強度、そして低い毒性により、化学処理、電力生成、艦船など重要な用途での人気のある選択肢となっています。TMC METALがチタン被覆銅を使用しています。 チタンフランジ あなたはアプリケーションに応じた適切なサイズの厚さを選択する必要があります。このアイテムは、特定の必要性に合わせて簡単に溶接され、加工することができます。したがって、これは温度交換器、反応容器、およびクリーナー反応器の製造において人気のある選択肢となっています。

チタン張り銅に関しては、品質が非常に重要です。チタン銅は、作業安全性と効率性を確実にするために、業界固有の基準に適合して製造されています。したがって、購入するチタン張り銅製品はすべて、安全性と品質について試験および認証済みである必要があります。選択するサービスプロバイダーは、TMC METALのように、同じタイミングで高品質なソリューションを提供する実績を持っているべきです。 ニッケルチタン線 . サイトを運営する会社は、お客様のニーズに最も適した製品を選定する際の経験と知識を備えており、製品が長期間にわたり確実に機能するために設置およびメンテナンスの解答を提供することができる必要があります。

定義されていない

チタン張り銅は、熱交換器、掃除機の反応槽、および反応容器の製造など、さまざまな用途があります。この製品は通常、船舶業界で船のプロペラを製造するために使用され、船の腐食への脆弱性を軽減します。さらに、チタン張り銅は、腐食性に非常に強く、毒性が低いことから航空宇宙産業にも利用できます。高い比強度を持つため、航空機部品の製造に理想的な素材として選ばれます。

当社は、希少金属および非鉄金属の加工・生産において26年の専門知識と実績を有しています。業界の発展を支えるため、専門的な知識を備えた多数の技術者および研究者を育成してきました。また、従業員の成長を支援するための開発プラットフォームも提供しています。専門スタッフがアフターサービスを含む包括的なサポートを提供し、お客様の懸念事項への対応、技術的支援、および発生しうるチタン被覆銅(Titanium clad copper)に関する課題の解決を実施します。さらに、お客様からのフィードバックを収集・分析することにより、製品品質および顧客サービスの向上に向けた必要な改善を継続的に行っています。

現代化された生産加工設備を備えた事業所。高度な金属加工に加え、精密加工および微調整加工も行うことができます。チタン張り銅部品の製造・加工も顧客の仕様書や設計図面に応じて行い、製品設計および開発にも参加可能であり、OEM・ODMにも対応しています。500平方メートルを超えるR&D施設、専門のR&Dスタッフおよび設備を保有しており、製品の開発および試験を支援することができ、多様な顧客の要望に応えるための各種加工設備も揃っています。

蘇州タムチュアン社は、加工会社であり、蘇州市に生産施設およびオフィススペース(面積2,000平方メートル)を有しています。当社は、各種希少金属および幅広い非鉄金属製品の製造を専門としています。チタン被覆銅製品の取引先は2,000社以上に及び、多数のパートナーと協力関係を築いています。また、熟練した研究開発(R&D)チームも擁しています。安定したサプライチェーンにより大量生産に対応可能であり、高精度な生産設備および工具も整備されています。さらに、専門的な品質管理チームが製品の品質を厳格に検査しています。これまでに、ビジネスパートナーとの良好な協業関係を築いてきました。

当社は、製品が事前に定められた規格および仕様に適合することを保証するため、厳格な品質管理プロセスを確立・実施しています。原材料のトレーサビリティおよびチタン被覆銅供給チェーンにおける品質管理能力を確保するため、高品質なサプライヤーを選定しています。ISO9001およびSGS認証を取得しており、これらは業界標準および国際標準に準拠しています。非鉄稀少金属産業の仕様に従い、当社チームは品質管理計画を作成し、品質検査および監査を実施しています。また、生産工程を記録・監視しています。