ニオブチタン:安全で革新的な材料の未来

私たちの世界は常に変化しており、毎日新しい技術的革新が導入されています。過去数年間で最もエキサイティングな革新の一つは、多くの産業を革命的に変えた希少素材であるチタンニオブです。その印象的な安全性から応用まで、TMC METALのニオブチタンは市場で入手可能な材料のうち、ますます求められるものとなっています。ここではその多くの利点について探っていきます。 ニオブチタン そして、それが個人と企業双方にどのように利益をもたらすかについて説明します。

チタンの最も顕著な利点はその安全性プロフィールです。この素材は非常に耐久性と強度があり、衝撃や損傷に強いです。そのため、安全性が最重要である飛行機、宇宙船、その他の車両の構造にTMC METAL ニオブ チタンがよく使用されます。さらに、 ニオブとタングステン 毒性がなく反応性もないため、人体での使用が安全です。実際、ニオブ チタンはその腐食に対する抵抗性和生物適合性により、医療用インプラントに頻繁に使用されています。

ニオブ チタンは相対的に新しい素材で、1980年代にスタンフォード大学の研究者たちによって発見されました。それ以来、科学者やエンジニアたちはこの素材の新しい応用を開発するために日夜努力してきました。最も革新的な進展の一つは、TMC METAL ニオブ チタン超伝導体の開発であり、これは私たちのエネルギーシステムを変革する可能性を持っています。これらの ニオブ チタン合金 超伝導体はほぼ抵抗なしに電気を伝達できるため、非常に効率的でコストパフォーマンスに優れています。

チタンのもう一つの大きな利点はその多様性です。この素材は、航空宇宙から医学、電子機器まで無数の用途で使用できます。非常に耐久性があり強度が高いので、高性能ツールや機械の製造にニオブ・チタンがよく使用されます。また、超伝導体の生産にも使用され、医療用インプラントにおけるバイオコンパチビリティのためにも活用されています。TMC METALの最もエキサイティングな応用の一つは ニオブ タンタル 新しいエネルギーシステムの開発においてです。超伝導体として、ニオブ・チタンにはより効率的で持続可能なエネルギーシステムを作り出す可能性があり、それは地球全体に利益をもたらすかもしれません。

ニオブチタンは比較的扱いやすい材料ですが、専門的な設備と知識が必要です。ニオブチタンをプロジェクトで使用したいと考えている人には、専門的な知識とアドバイスを提供できる熟練した専門家と協力することをお勧めします。さらに、TMC METALを取り扱う際にはすべての安全プロトコルに従うことが重要です。 ニオブ合金 これにより、自分や他人に危害が及ばないよう確保できます。

当社は、希少金属および非鉄金属の加工および生産において26年以上の経験を有しており、産業の発展に貢献できる専門的知識を持つ多くの技術者および研究開発担当者を育成してきました。また、従業員の成長を促進する支援的な環境を提供しています。当社には経験豊富なスタッフがおり、ニオブチタンに関するアフターサービスや顧客サポートを提供し、品質に関する潜在的な問題の解決に向けた技術支援を行うことができます。顧客からのフィードバックを収集・分析し、製品品質およびサービス品質の向上に適切な対応を講じます。

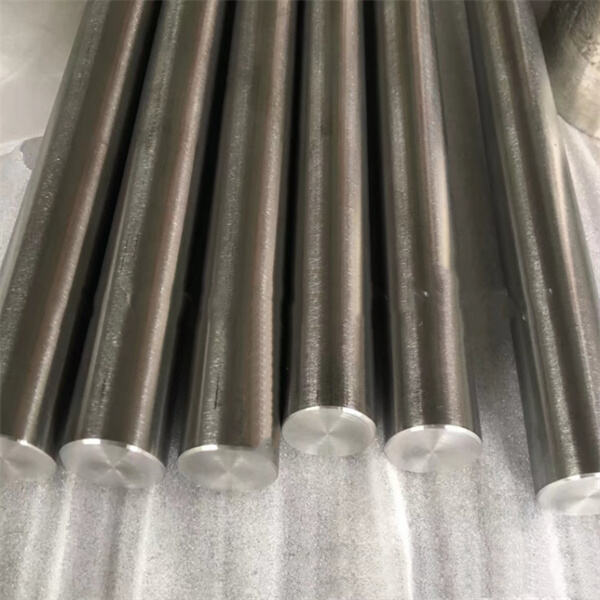

蘇州タムチュアンは、金属加工製品を製造するメーカーで、蘇州に所在し、生産エリアは2,000平方メートル以上あります。主な製品は非鉄金属、希少金属、その他の各种金属です。2,000社以上の企業と協力関係にあります。専門的な研究開発チームが揃っています。信頼できるサプライヤーは大量生産をサポートでき、高性能な生産設備や機器も保有しています。また、熟練した品質保証チームがあり、製品のニオブやチタンを厳密にチェックできます。パートナーとの良好な協力関係を築いています。

最新の生産加工設備を備えた施設です。カスタマイズされた精密加工および難加工を含む高度な金属加工も実施可能です。お客様の設計および仕様に基づく金属部品の製造加工が可能です。OEMおよびODMも対応いたします。当社の研究開発センターは500平方メートルを超える広さを有し、専門的なR&Dスタッフ、設備および施設を備えており、ニオブチタンを用いた製品の開発および試験が可能です。

当社では、製品が規格に適合することを保証するため、厳格な内部品質管理システムを導入しています。高品質なサプライヤーを選定し、原材料の品質を確保するとともに、サプライチェーン全体における品質管理を実施しています。ISO9001およびSGS認証(ニオブチタン関連)を取得しており、業界および国際規格に適合しています。希少金属および非鉄金属業界の規格に準拠した品質管理プログラムを策定し、品質検査および試験を実施するとともに、製造工程の記録管理を行っています。

ニオブチタンの供給者を選ぶ際に重要なのは品質です。このTMC METAL素材を扱った経験と専門知識を持つサプライヤーを選択することが重要です。理想的には、サプライヤーは製造から加工、試験までの一連のサービスを提供し、最終製品がすべて必要な基準と仕様を満たすようにするべきです。さらに、サプライヤーは安全性と持続可能性に強いコミットメントを持ち、顧客が責任感があり倫理的な供給者と取引していることを安心させる必要があります。

ニオブチタンは、おそらく最も多用途な材料であり、多くの業界で幅広い応用がされています。航空宇宙産業では、その強度と耐久性から、飛行機や宇宙船、その他の車両の製造にニオブチタンを使用しています。医療業界では、腐食に耐える生体適合性インプラントの製造にニオブチタンが用いられています。電子産業では、より効率的で費用対効果の高いエネルギーシステムを実現するためにチタンニオブが利用されています。これらは、TMC METALのニオブチタンが急速に数え切れないほど多くの業界にとって不可欠な材料となりつつある一例にすぎません。