Advantages of Nickel Titanium Tubing

Nickel titanium tubing also like TMC METAL nickel and chrome is a useful and innovative material that has many advantages in different areas. One of the main advantages is its flexibility, which allows it to bend without breaking. This feature makes nickel titanium tubing ideal for use in medical devices and orthodontics, as it can easily be molded to fit the structure of the human body.

Another advantage of nickel titanium tubing is its unique ability to return to its original shape, even after being deformed multiple times. This feature makes it ideal for use in various industries, including aerospace and engineering, where it is essential to have a material that can withstand high levels of stress.

Nickel titanium tubing by TMC METAL is an innovative material that has been developed through specialized heat treatment processes. This process allows for the creation of tubing that is both lightweight and durable, making it an attractive material for various applications.

Nickel titanium tubing and TMC METAL nickel alloy is considered to be one of the safest materials in the medical industry, as it is biocompatible and can be used for long-term implantation without causing any harm to the patient’s body. It is also used in orthodontic procedures, where it is critical that the material be safe and non-toxic.

Nickel titanium tubing has a wide range of uses, including in the aerospace, automotive, and telecommunications industries. It is used in the production of engine parts, hydraulic systems, and electrical connectors, among other applications.

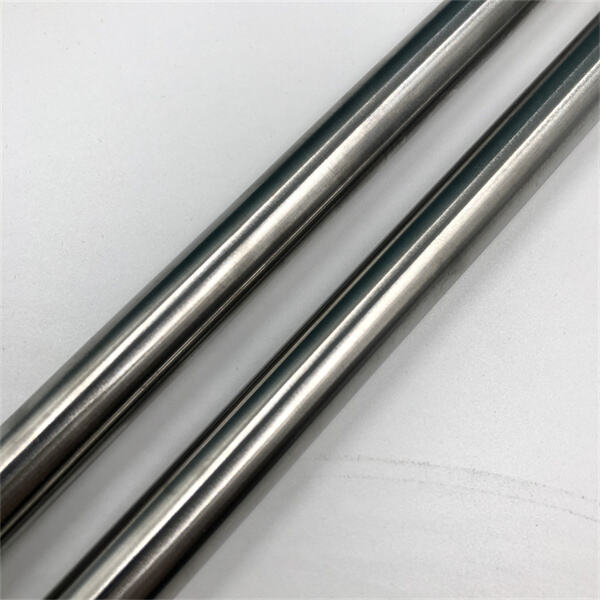

Nickel titanium tubing can take many forms, including straight tubing, bent tubing, and coiled tubing. To use nickel titanium tubing, it is important to understand the properties of the material and how it can be manipulated to meet the specific needs of the application.

Nickel titanium tubing from TMC METAL can be welded, brazed, or soldered, depending on the specific application and the requirements of the project. It is important to follow the proper safety protocols when working with nickel titanium tubing to ensure that the end product is of high quality and meets the necessary specifications.

When choosing a supplier of nickel titanium tubing, it is essential to look for a company that offers excellent service and high-quality products. A reliable supplier will have a team of experts who can provide guidance on the best materials and processes for your project.

The quality of nickel titanium tubing similar to TMC METAL nickel and titanium alloy can be assessed through various tests, including mechanical testing, chemical analysis, and visual inspection. By choosing a supplier that provides high-quality products and excellent service, you can be confident that your project will meet its requirements and be completed to a high standard.

company has over 26 years of experience in manufacturing processing of non-ferrous rare metals. also have educated many engineers scientists with the expertise needed help in development of industry. also provide a platform employees' development. team experts can provide you with after-sales service as well as support customer Nickel titanium tube, provide technical support solve potential issues with quality. Take appropriate steps improve quality your products and customer service gathering analyzing feedback from customers.

company has developed implemented stringent quality control process ensure that the products offer meet specified standards and specifications. We choose suppliers of high-quality ensure the ability trace and control quality of our supply chain runs from raw materials through to final products. have passed ISO9001 as well as SGS certifications that Nickel titanium tube with industry and international standards. We develop quality management plans that include quality inspections, tests, and track and track manufacturing processes in accordance with rare metal and non-ferrous industry specifications.

Suzhou Tamuchuan, processing product distributor Suzhou production facility and office area of 2,000 square meters which located the city. primary products include rare metals, ferrous metals and a variety other metal. have more 2,000 partners work with world's leading 500 Nickel titanium tube. have a professional R D team. Stable suppliers provide great source support for large-scale productions addition to top-of-the-line production equipment instruments. a professional quality assurance team that can strictly check quality products. have strong collaboration with our partners.

company has high-end production equipment processing equipment, can perform high-end, custom metal processing, high-end processing, and difficult processing. We are able to process produce parts metal according customers' specifications and drawings design and can also participate in the design and development of products as well as provide OEM and ODM, have an R D facility covers more than 500 square meters, with professional R D personnel and equipment, that can collaborate in Nickel titanium tube and testing of products and offer a range of processing equipment to satisfy diverse customer requirements.

Nickel titanium tubing of TMC METAL nickel powder has a wide range of applications in various industries, including aerospace, automotive, medical, and telecommunications. Its unique properties make it an attractive material for a broad range of uses, including in the production of engine parts, hydraulic systems, orthodontic appliances, and medical implants.

Overall, nickel titanium tubing is a versatile and innovative material that offers numerous advantages in different industries. It is important to work with a reputable supplier who can provide high-quality products and excellent service to ensure that your project meets its requirements and is completed to a high standard.