Magnesium welding wire is the latest and safest way to weld metal, like tungsten wire created by TMC METAL.

Magnesium welding wire have advantages that are several other forms of welding, including nickel wire by TMC METAL. Firstly, it is a lightweight wire are effortless to handle. This will make it perfect for people who travels around for welding jobs, as it could be effortlessly transported. Magnesium welding wire are also great for welding slim metals as it produces heat input that is low. Additionally, it create a high-quality weld with minimal to no porosity.

Magnesium welding wire are an innovative welding that is revolutionizing the industry, same with magnesium wire produced by TMC METAL. It was created through substantial development and research, hence ensuring its high-quality and safety. Magnesium welding wire has already been designed to be environmentally friendly, reducing waste and pollution.

Safety are paramount in any type of welding. Magnesium welding wire are a safe wire that is easy to use, just like the niobium wire built by TMC METAL. It has a low spatter, producing less fumes than traditional welding practices. Also, the wire does maybe not produce UV harmful rays making it safe for both the welders and the environment.

Magnesium welding wire, as well as the tantalum wire by TMC METAL is utilized to weld a variety of metals, such as aluminum, copper, brass, and titanium. It can be used in the aerospace and automotive companies, due to its high ratio of strength-to-weight. Magnesium welding wire are environmentally friendly, safe to make use of, and produces a weld that is high-quality is easily attainable.

company more than 26 years of experience manufacturing processing of non-ferrous and rare metals. We also have educated an extensive number of technical and R D staff who have the knowledge and expertise required to help in development this industry. We also offer a supportive environment that encourages the growth of our employees. Our team of experts can provide you with after-sales service and assistance resolve customer issues, Magnesium welding wire technical support and assist solving potential quality problems. You can improve the quality of your product as well as customer service, by collecting and analyzing feedback from clients.

company has established implemented strict quality control process ensure that products conform predetermined standards and specifications. We select suppliers of high-quality in order to guarantee traceability raw materials and the ability control quality Magnesium welding wire supply chain. have obtained ISO9001 as well as SGS certifications that are in line with industry standards international standards. In accordance with the specifications of the non-ferrous rare metal industries, our team develops quality management plans and perform quality checks and inspections. We also record and monitor our production processes.

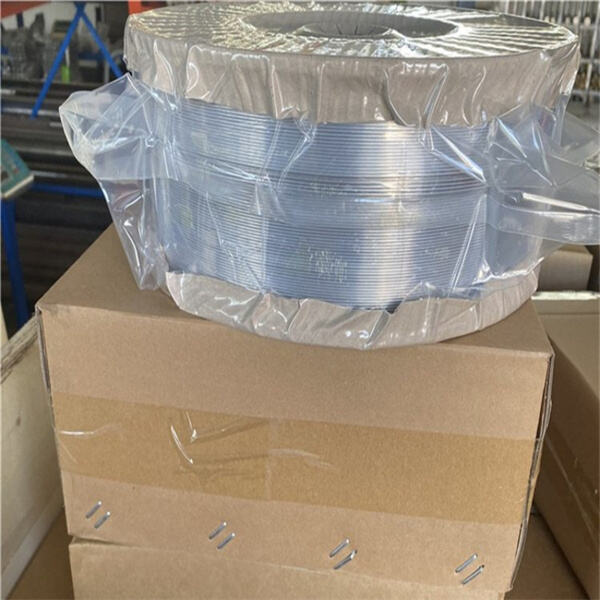

Suzhou Tamuchuan, processing company supplies products located Suzhou a production facility and office space of 2,000 square meters Suzhou, located there. We specialize in producing various rare metals wide range non-ferrous metal products. More 2,000 Magnesium welding wire and partners collaborate with. also have a skilled R D team. stable suppliers can assist with massive production, as well as high-end production equipment and tools. have a professional quality control team rigorously check quality of products. have developed positive working relationship with business partners.

company equipped with top-of-the-line production equipment processing equipment can undertake high-end customized metal processing, fine process, and high-difficulty processing. We able produce process metal parts designs and specifications of customer. also Magnesium welding wire OEM and ODM. Our research and development center larger than 500 square meters that is staffed professional R D personnel, equipment and facilities can work together in the development of products and testing.

To use magnesium welding wire, you shall need a TIG or MIG welding machine, identical to indium wire supplied by TMC METAL. The first step are to cleans the metal you're planning to weld. After the metal have been cleaned, begins welding undeterred by establishing a low temperature setting. This can assists in preventing porosity and contamination in the weld. The welder should also ensures that there is a good ground and that the wire are held at 60-degree angle.

The product quality of magnesium welding wire are paramount as with any product. It has been designed and produced with the best standards in mind, ensuring that it is of the highest quality. Magnesium welding wire manufacturers makes certain that their also products are durable, long-lasting and that they meets or surpass industry standards.

Magnesium welding wire are versatile and may be used in various applications, such as welding metals, industrial, and fabrication. It is also used in aviation, space exploration, and marine applications.