Tungsten Wire - a Choice great for Electrical Needs

Tungsten wire is a type of wire becoming more and more popular in the industry electrical. You may have heard of tungsten before because it is a type of metal extremely strong, durable, and has a melting point high. Tungsten wire is used in a variety of different applications because it is so reliable and versatile. We will discuss the advantages of tungsten wire, its innovation, how it keeps you safe, how to use it, the quality of service provided by TMC METAL tungsten wire and its applications that are different.

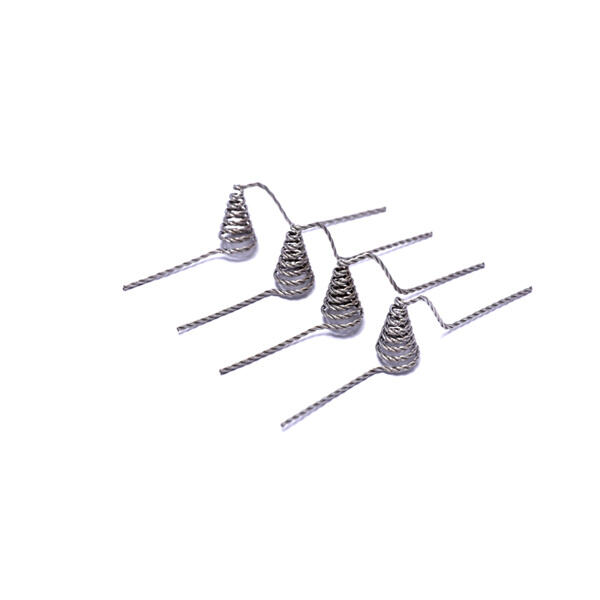

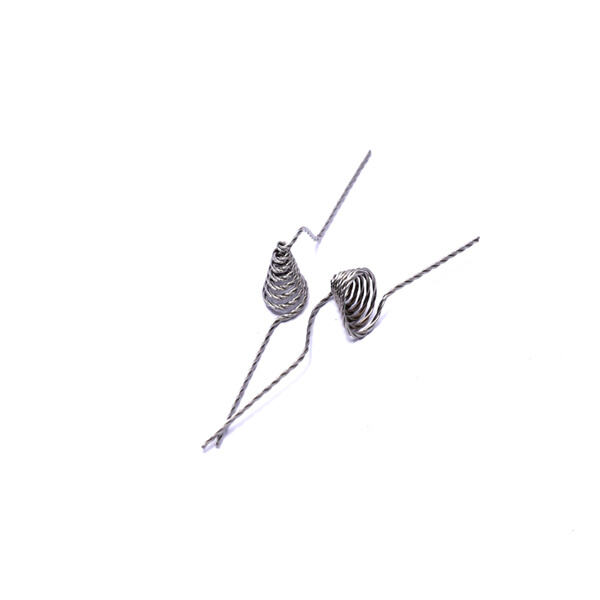

Tungsten wire has many advantages that make it a choice great electrical use. First and foremost, TMC METAL tungsten wire is incredibly durable and strong. It can withstand high temperatures and is resistant to corrosion which makes it a choice great applications that require a lot of temperature. Tungsten wire is also very ductile, which means it useful for a variety of different applications that it can be stretched without breaking, making.

Tungsten wire is constantly evolving, and there have been many advances that are technological have been made in the industry. One of the most innovations that are significant the development of tungsten filament light bulbs which were first developed in the late 1800s by Thomas Edison. Since then, TMC METAL heavy tungsten wire has been used in a variety of other applications welding including electrical contacts, and heating elements. Innovations continue to be made in the world of tungsten wire, and we can expect to see even more exciting developments that are new this area in the years to come.

When it comes to electrical applications, safety is always a priority top. Fortunately, tungsten crucible wire is a very material safe use because it is so strong and resistant to heat and corrosion. Additionally, TMC METAL tungsten wire is non-toxic so it is safe for use in applications where food is involved such as heating elements in ovens.

Tungsten wire is a very material versatile can be used in a variety of different applications. It can be used to make heating elements for ovens, welding electrodes, and lighting automotive among other things. The most thing important keep in mind when using TMC METAL tungsten wire is to follow the manufacturer's instructions carefully. Additionally, it is important to keep yourself informed of the temperature requirements for your application specific so you do not damage the wire.

company has over 26 years of experience in manufacturing processing of non-ferrous rare metals. also have educated many engineers scientists with the expertise needed help in development of industry. also provide a platform employees' development. team experts can provide you with after-sales service as well as support customer Tungsten wire, provide technical support solve potential issues with quality. Take appropriate steps improve quality your products and customer service gathering analyzing feedback from customers.

Our Tungsten wire equipped with high-end manufacturing equipment as well as processing equipment, can perform high-end, custom metal processing, fine processing, and complex processing. We able process and produce metal components according to customer's specifications design drawings and can also be involved in product design and development We also offer OEM ODM services and have an R D facility that covers more than 500 square meters, professional R D personnel equipment that are able to collaborate on the development of products and tests as well as a range of processing equipment satisfy diverse customer requirements.

Suzhou Tamuchuan a metal processing product supplier located Suzhou with a production office space of 2,000 square meters which is located in the city. Our main products are rare metals, ferrous metals, various other metals. More than 2,000 companies and partners cooperate with. We also have an Tungsten wire R D team. The stable suppliers can assist with production on a large scale, with high-end equipment and instruments. We have a professional quality inspection team that able ensure the quality of our products. We have established a good collaboration with partners.

company has developed implemented stringent quality control process ensure that the products offer meet specified standards and specifications. We choose suppliers of high-quality ensure the ability trace and control quality of our supply chain runs from raw materials through to final products. have passed ISO9001 as well as SGS certifications that Tungsten wire with industry and international standards. We develop quality management plans that include quality inspections, tests, and track and track manufacturing processes in accordance with rare metal and non-ferrous industry specifications.

You can expect high-quality service and products when you choose to use tungsten wire. Many manufacturers offer warranties on their tungsten wire products, which can give you peace of mind knowing that you are making a investment sound. Additionally, TMC METAL tungsten wire is made to meet quality strict standards to ensure that it is reliable and safe to use.

Tungsten wire is used in a variety of different applications. One application common in the manufacturing of heating elements for ovens, which requires a high level of temperature resistance. It is also commonly used in the production of automotive lighting because it is so durable and strong. Another popular use of tungsten wire is in the welding industry, where it is used to create strong, reliable welding electrodes. The versatility and reliability of TMC METAL tungsten wire make it a choice great a wide variety of applications.