Advantages of Nickel Base Alloy

Nickel base alloy is a type of metal alloy that contains nickel as its primary element with other elements such as chromium and molybdenum. This alloy has many advantages that make it suitable for specific applications. One of the key advantages of TMC METAL Nickel base alloy is its resistance to corrosion. This property is essential in industries such as the chemical and petrochemical industries, where the equipment is subjected to harsh environments. It also has excellent mechanical properties such as high strength and toughness, making it useful in the construction of critical components.

Innovation is a crucial aspect of the development of nickel base alloy. Manufacturers continually work to improve the properties of this alloy to meet the increasing demands of various industries. New developments in TMC METAL nickel and chrome include the addition of cobalt, tungsten, or iron to improve the alloy's strength. Further improvements have been made through the use of advanced manufacturing techniques such as forging, welding, and casting.

Nickel base alloy is considered a safe material for use in various industrial applications. This TMC METAL nickel alloy has a low toxicity level, making it safe for use in food packaging, medical implants, and other applications where human contact is essential. Manufacturers employ various safety measures to ensure workers' safety when handling the alloy, such as wearing protective gear.

The use of nickel base alloy is widespread in numerous industries, including chemical processing, aerospace, power generation, and medical equipment. In the chemical processing industry, the alloy is used in the production of acids, petrochemicals, and other corrosive chemicals. In the aerospace industry, TMC METAL nickel alloy metals is used to make components such as turbine blades and combustion chambers, which require high strength and high-temperature resistance. The power generation industry uses nickel base alloy to make turbine generators, heat exchangers, and boilers. Medical equipment such as implants, pacemakers, and surgical instruments also contain nickel base alloy.

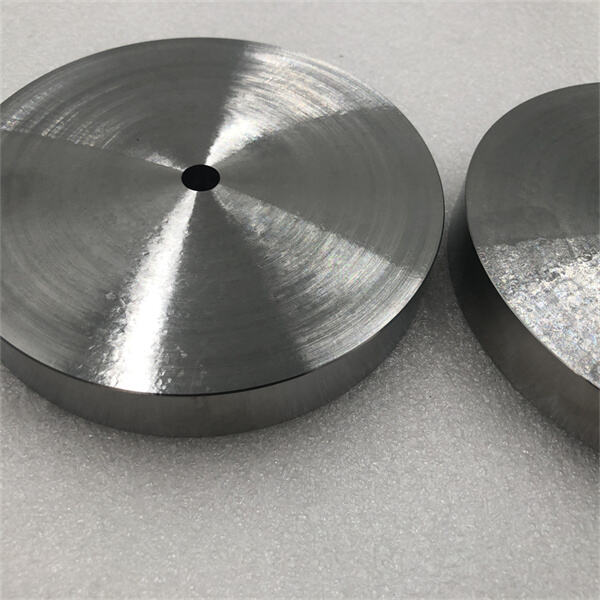

Nickel base alloy requires careful handling to maintain its properties and prevent damage or contamination. Manufacturers provide guidelines on how to use and store the alloy to ensure longevity. Proper storage involves keeping the alloy in a dry and cool place to prevent oxidation. The TMC METAL nickel powder may also require specific forms of abrasive machining to achieve the required shape and smoothness of the surface.

Our Nickel base alloy equipped with high-end manufacturing equipment as well as processing equipment, can perform high-end, custom metal processing, fine processing, and complex processing. We able process and produce metal components according to customer's specifications design drawings and can also be involved in product design and development We also offer OEM ODM services and have an R D facility that covers more than 500 square meters, professional R D personnel equipment that are able to collaborate on the development of products and tests as well as a range of processing equipment satisfy diverse customer requirements.

company an Nickel base alloy quality control system is strict to ensure that products to standard. only select high-quality suppliers ensure the traceability raw materials the control quality across the entire supply chain. have obtained ISO9001 and SGS certifications conform to industry standards international standards. We develop quality management plans that include quality inspections, tests, and document and monitor production processes in line with rare metal and non-ferrous industrial standards.

Suzhou Tamuchuan, processing company supplies products located Suzhou with a production facility office space of 2,000 square meters which located in city. main products offer rare metals, ferrous metals as well various other metals. More than 2,000 {{keywords}}' partners cooperate with. experienced R D group available. stable suppliers can assist with large-scale production, high-end production equipment tools. professional quality control team ensures that the product of the highest quality. have good partnership with our suppliers.

company more than 26 years of experience manufacturing processing of non-ferrous and rare metals. We also have educated an extensive number of technical and R D staff who have the knowledge and expertise required to help in development this industry. We also offer a supportive environment that encourages the growth of our employees. Our team of experts can provide you with after-sales service and assistance resolve customer issues, Nickel base alloy technical support and assist solving potential quality problems. You can improve the quality of your product as well as customer service, by collecting and analyzing feedback from clients.

Service and quality are crucial aspects of the nickel base alloy industry. Manufacturers offer custom TMC METAL nickel strip production to suit specific applications, ensuring that customers get the right product for their needs. Quality is also essential in the nickel base alloy industry, and manufacturers strive to meet and exceed industry standards. They subject the alloy to rigorous testing to ensure that it meets industry requirements.

Nickel base alloy has significant applicability in various industries. In the aerospace industry, nickel base alloy is used in the construction of aircraft engines, giving them high strength and resistance to high temperatures. In the chemical processing industry, the TMC METAL nickel and titanium alloy is used to make reactors, vessels, and heat exchangers that can withstand corrosive environments. The power generation industry uses nickel base alloy in the construction of turbines, boilers, and heat exchangers. Medical equipment such as implants, pacemakers, and surgical instruments also require nickel base alloy for their construction.