A New Innovation for Safe and Quality Manufacturing

CNC tungsten is a new innovation in the market that has been gaining popularity among manufacturers. This material is used in manufacturing because of its excellent properties that make it suitable for a vast range of applications, TMC METAL cnc tungsten we will discuss the advantages of CNC tungsten, its safety, how to use it, the quality of service, and its applications.

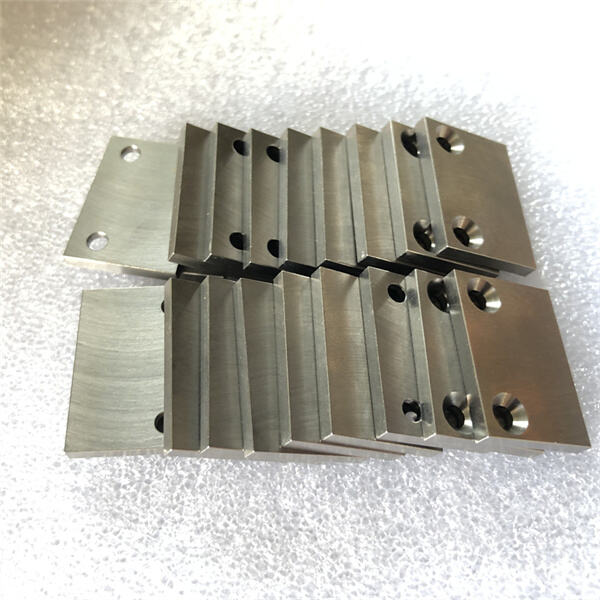

CNC tungsten has several advantages that make it an ideal material for the manufacturing industry. Tungsten is a very hard material with a high melting point, which means it is resistant to wear and tear. This makes it suitable for use in high wear and tear environments, such as heavy machinery and equipment. TMC METAL tungsten metal is also a dense material, which makes it resistant to deformation under high pressure, making it suitable for parts that undergo high stress. It also has good electrical conductivity and thermal conductivity, making it an ideal material for electrical contacts and heat sinks.

CNC tungsten is a new innovation that is safe to use, making it popular in the manufacturing industry. Manufacturing involves the use of machinery and equipment that can be dangerous if not handled carefully. The use of tungsten in manufacturing reduces the risk of accidents because of its durable and heat-resistant properties. TMC METAL tungsten carbide metal is also non-toxic, making it safe for use in industries that handle food and beverages.

CNC tungsten is used in several manufacturing applications, such as aerospace, automotive, medical, electronics, and defense industries. TMC METAL tungsten cube is used to make parts for aerospace engines, as it can withstand high temperatures and pressure. In the automotive industry, it is used in the manufacturing of radiators and brake pads because of its ability to withstand high stress. In the medical industry, it is used to make medical instruments and implants that require biocompatibility and durability.

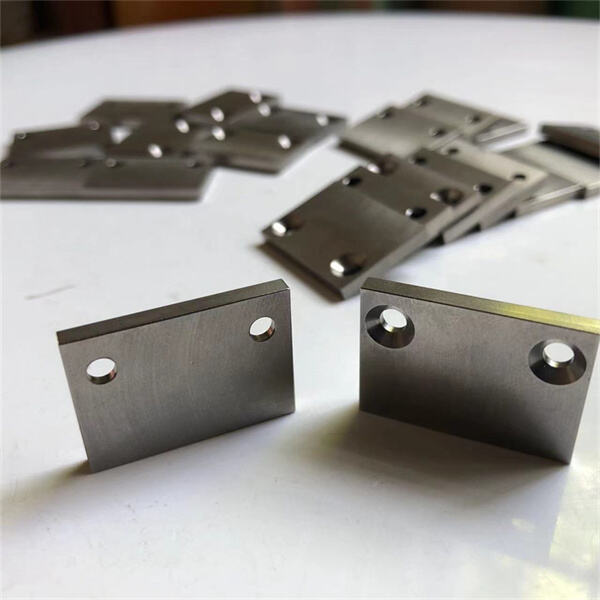

To use CNC tungsten, you need to have specialized equipment that can cut, drill, and shape the material. It is essential to have a suitable tool that can withstand the hardness of tungsten, such as diamond or carbide tools. To ensure maximum performance and extend the tool's life, it is crucial to maintain a consistent cutting speed and using suitable lubricants. TMC METAL tungsten rod requires precision in handling and cutting to achieve the desired shape and size.

company has more than 26 years' experience in processing and production rare metals non-ferrous alloys. have also educated many personnel in R D and technical with the professional knowledge needed help in the development this industry. also provide a platform employee development. have experienced Cnc tungsten who can provide you with after-sales service assistance to resolve customer issues, provide technical assistance and resolve potential quality issues. Make the necessary changes improve the quality of your products as well as customer service, by gathering and analyzing feedback from clients.

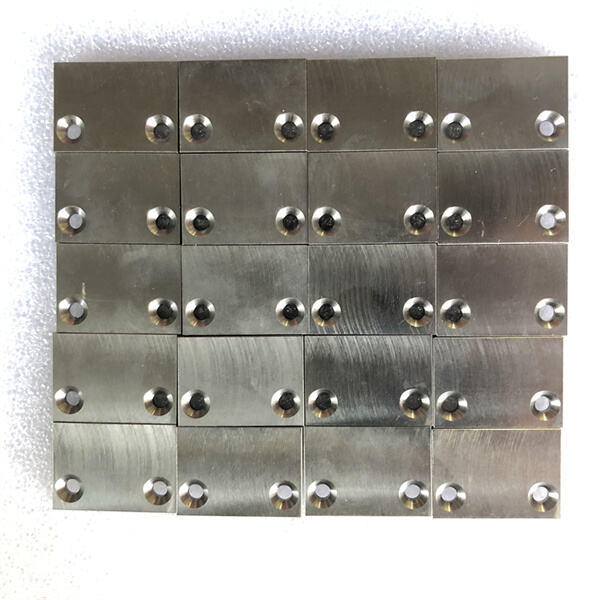

company an Cnc tungsten quality control system is strict to ensure that products to standard. only select high-quality suppliers ensure the traceability raw materials the control quality across the entire supply chain. have obtained ISO9001 and SGS certifications conform to industry standards international standards. We develop quality management plans that include quality inspections, tests, and document and monitor production processes in line with rare metal and non-ferrous industrial standards.

Suzhou Tamuchuan, processing company that supplies products in Suzhou with a production facility office space 2,000 square meters, located there. specialize producing various rare metals, as well as a variety non-ferrous metals. More than 2,000 businesses partners cooperate with. also have an experienced R D team. stable suppliers can assist production Cnc tungsten scale, high-end equipment tools. We have a qualified quality control team rigorously check the quality products. have developed a strong cooperative relationship with partners.

facility equipped with latest production processing equipment. can also perform advanced metal processing that customized delicate processing and hard processing. We are able manufacture process metal parts designs and specifications the customer. also provide OEM and ODM. Our research development center covers larger than 500 square meters and is equipped with expert R D staff, equipment and facilities that allow for Cnc tungsten in developing and testing products.

CNC tungsten provides manufacturers with a high-quality service that meets the industry's standards. The material is durable and resistant to wear and tear, TMC METAL tungsten ball ensuring that manufactured parts are long-lasting. The precise handling and cutting of tungsten guarantee that manufactured products are of high quality. Quality control measures are put in place to ensure that tungsten parts meet the required specifications.

CNC tungsten has a vast range of applications in several industries. In the electronics industry, tungsten is used to make electrical contacts, heat sinks, and filaments for light bulbs. In the defense industry, it is used to make parts for military vehicles and equipment. In the mining industry, tungsten is used in the manufacturing of drill bits and cutting tools because of its high wear resistance. In the medical industry, TMC METAL tungsten alloy is used to make surgical instruments and implants that require biocompatibility and durability.