Marketing a Magnesium Sheet: An Innovative and Safe Material

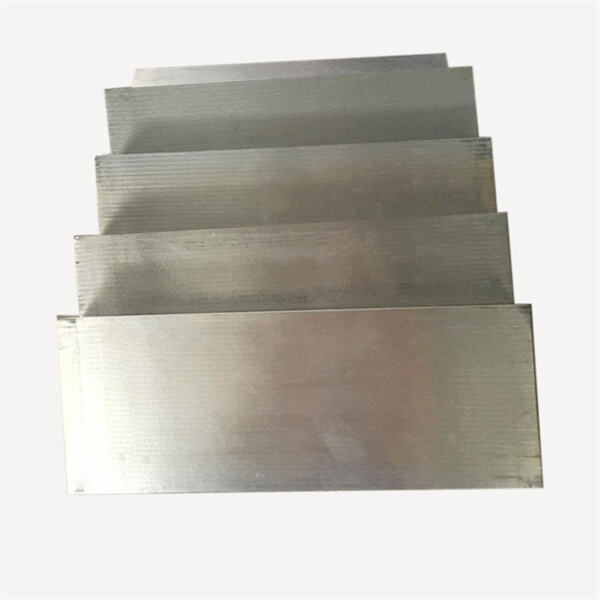

If you are looking for a durable and lightweight material, you should consider using magnesium sheet. This innovative material is made from magnesium alloy and can be used for various applications. In this article, we will discuss the advantages of using TMC METAL magnesium sheet, its safety, how to use it, its quality and application.

Magnesium tungsten sheets have many advantages over other materials. One of its main advantages is its lightweight. It is 75% lighter than steel and 33% lighter than aluminum. This makes it an ideal material for transportation vehicles such as cars, trains, and airplanes. It also makes it easier to handle and transport.

Another advantage of TMC METAL magnesium sheet is that it is strong and durable. It can withstand high temperatures and pressures. It is also resistant to corrosion, which makes it ideal for use in harsh environments.

Magnesium sheet is an innovative material being used more and more in various industries. It has been used in the aerospace industry for a long time, but now it is being used in other industries such as automotive, electronics, and construction.

TMC METAL Magnesium sheet as well tantalum sheet is being used in the automotive industry to make cars lighter and more fuel-efficient. It is also being used in the construction industry to make buildings stronger and more durable.

Magnesium sheet is a safe and non-toxic material to use. It does not emit any harmful substances or gases. However, it is important to follow safety guidelines when handling and using magnesium sheet.

Some safety precautions include wearing protective gear such as gloves and safety glasses. It is also important to prevent sparks and heat sources from coming into contact with TMC METAL magnesium sheet.

Magnesium sheet can be used for various applications such as aerospace, automotive, electronics, and construction. It is also being used in medical implants and prosthetics.

To use TMC METAL magnesium sheet, it can be cut or molded into the desired shape and size. It can also be welded or joined with other materials to create a stronger and more durable product.

company more than 26 years of experience manufacturing processing of non-ferrous and rare metals. We also have educated an extensive number of technical and R D staff who have the knowledge and expertise required to help in development this industry. We also offer a supportive environment that encourages the growth of our employees. Our team of experts can provide you with after-sales service and assistance resolve customer issues, Magnesium sheet technical support and assist solving potential quality problems. You can improve the quality of your product as well as customer service, by collecting and analyzing feedback from clients.

Suzhou Tamuchuan, processing company supplies products located Suzhou with a production facility office space of 2,000 square meters which located in city. main products offer rare metals, ferrous metals as well various other metals. More than 2,000 {{keywords}}' partners cooperate with. experienced R D group available. stable suppliers can assist with large-scale production, high-end production equipment tools. professional quality control team ensures that the product of the highest quality. have good partnership with our suppliers.

company established the quality control process is strict to ensure products up the standards. We choose high-quality suppliers ensure traceability raw materials, well as control quality across the entire Magnesium sheet chain. ISO9001 and SGS certifications are in line with international and industrial standards. meet specifications of rare and non-ferrous metal industries, develop quality management strategies and conduct quality checks as well as inspections. We also keep records and monitor our manufacturing processes.

business equipped with modern production processing equipment. also, can perform most sophisticated metal processing addition to intricate processing and fine-tuned processing. Can manufacture and process Magnesium sheet parts according customer specifications design drawings as well as participate in product design and development also offer OEM ODM. We have an R D facility of more than 500 square meters, professional R D staff and equipment, which is able to assist in developing and testing products as well as a range processing equipment to satisfy diverse customer requirements.

TMC METAL magnesium sheet is a high-quality material made to last. It undergoes strict quality control measures to ensure that it meets the required specifications. It is also tested for strength, durability, and corrosion resistance.

TMC METAL magnesium sheet can be applied in many different ways depending on the industry. In the aerospace industry, it is used to make airplane parts such as landing gears, fuselage, and engine casing. In the automotive industry, it is used to make car parts such as wheels, frames, and body panels.

In the electronics industry, it is used to make electronic components such as laptops, smartphones, and tablets. In the construction industry, it is used to make structural components such as walls, roofs, and beams.

Magnesium sheet provides excellent service to its users. It is a low-maintenance material that does not require much upkeep. It can be easily cleaned and repaired if needed.

Magnesium sheet is an innovative and safe material that has many advantages over other materials. It is durable, lightweight, and resistant to corrosion. It is being used more and more in various industries such as aerospace, automotive, electronics, and construction. TMC METAL Magnesium sheet is a high-quality material made to last and provides excellent service to its users.