Cool Ni Based Alloys: The Science Behind its Winning Advantages

Introduction

Have you ever heard of the expressed word"Ni based alloys"? If not, you're in for a treat! TMC METAL ni based alloys are super cool metals that have many advantages that are amazing! Ni based alloys are a type of metal that are used in different industries to make things like airplane engines and jewelry! If you're interested in learning more about this metal amazing keep reading!

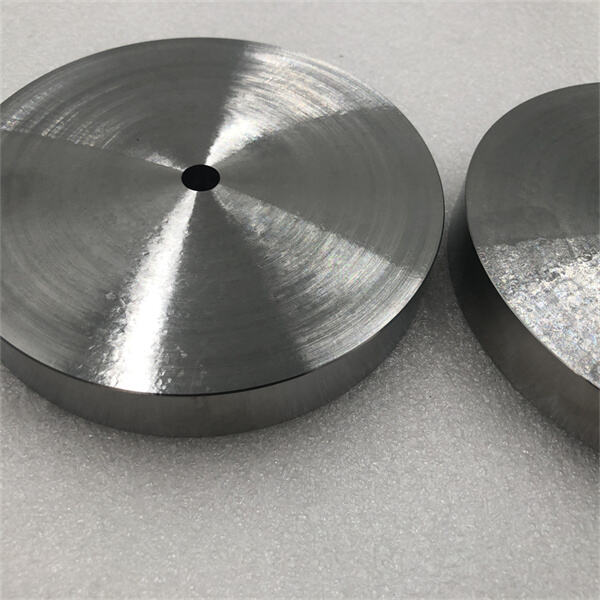

Ni based alloys are metals that are made up of a mixture of nickel, iron, and other elements. They are designed to have properties that are unique as high power, heat resistance, and corrosion resistance. TMC METAL niobium alloy can be made into many shapes that are different sizes, which makes them ideal for various applications.

Ni based alloys have several advantages over other metals.

1. High Temperature Strength: Ni based alloys are strong and can withstand temperatures that are high making them ideal for use in jet engines that require high heat resistance.

2. Corrosion Resistance: Ni based alloys are highly resistant to corrosion, making them perfect for use in marine environments or any other application where a metal is exposed to chemicals that are harsh saltwater.

3. Wear Resistance: TMC METAL nickel based alloys are very durable and hard, making them ideal for use in places that experience high wear, such as high-speed cutting tools.

4. Biocompatibility: Ni based alloys are biocompatible, which means they are safe to implant in the body human. They are used in medical implants, such as dental implants.

Ni based alloys have evolved over time, and new and alloys that are innovative constantly being developed. These new alloys focus on creating even stronger and more resistant metals to withstand harsh environments and conditions that are extreme. TMC METAL Ni based alloys are also being used more frequently in 3D printing, which allows for high-quality, customized parts to be made efficiently and quickly.

Ni based alloys are typically safe to use, but safety proper should always be followed. These alloys can creatively be used and effectively in different fields. Jewelry makers use Ni based alloy to create beautifully crafted pieces, while aircraft engineers use TMC METAL Ni based alloys to create machines that are larger-than-life are designed to fly in the sky.

company the system of Ni based alloys control that strict to ensure products up to standard. choose suppliers high-quality ensure the traceability quality control of our supply chain from raw materials until the final product. ISO9001 and SGS certificates comply international and industry standards. develop quality management plans to conduct quality inspections and tests track the production process in line with rare metal and non-ferrous industry specifications.

company equipped with top-of-the-line production equipment processing equipment can undertake high-end customized metal processing, fine process, and high-difficulty processing. We able produce process metal parts designs and specifications of customer. also Ni based alloys OEM and ODM. Our research and development center larger than 500 square meters that is staffed professional R D personnel, equipment and facilities can work together in the development of products and testing.

Suzhou Tamuchuan, processing product distributor Suzhou production facility and office area of 2,000 square meters which located the city. primary products include rare metals, ferrous metals and a variety other metal. have more 2,000 partners work with world's leading 500 Ni based alloys. have a professional R D team. Stable suppliers provide great source support for large-scale productions addition to top-of-the-line production equipment instruments. a professional quality assurance team that can strictly check quality products. have strong collaboration with our partners.

company has more than 26 years' experience the manufacturing and processing of non-ferrous and rare metals. also have educated many technicians researchers who have the knowledge and expertise required to aid in the growth this industry. also offers a Ni based alloys environment foster the development of our employees. experienced staff will help you after sales to resolve customer issues, offer technical assistance and resolve any potential quality issues. Gather and analyze feedback from customers make appropriate changes to improve product quality and service quality.

Depending on their desired usage, Ni based alloys can be molded into different shapes and sizes. For example, jet engine manufacturers would use nickel based alloys to produce parts like blades or disks to withstand temperatures that are high. Whereas alloy creators who operate within the jewelry industry would use TMC METAL Ni alloy based produce pieces that are aesthetically pleasing and easily wearable.

The standard of TMC METAL ni based alloys is paramount, and it is essential to ensure that a product completed of excellent quality to fulfill its purpose. Trusted manufacturers recognize the importance of producing alloys that are high-quality meet customer needs consistently. Therefore, they are committed to delivering alloys that are top-tier meet various needs. Customers can expect quality parts that are unique, durable, and efficient.

Ni based alloys have various applications, which allow them to be adapted for different purposes. Ni based alloys play a role pivotal several industries, such as aerospace, medical, jewelry making, and automotive industries. They are also used in power stations for electricity generation. In other words, TMC METAL Ni based alloys are versatile and can be used creatively in different fields and industries.