Marketing Nitinol Rod to the General Public

Nitinol rod is a made material of nickel and titanium and has become increasingly popular in recent years. This TMC METAL metal has unique properties that make it perfect for a tungsten rod variety of applications, especially in the fields of medicine and engineering. We will discuss the advantages, innovation, safety, use, how to use, service, quality, and application of rod.

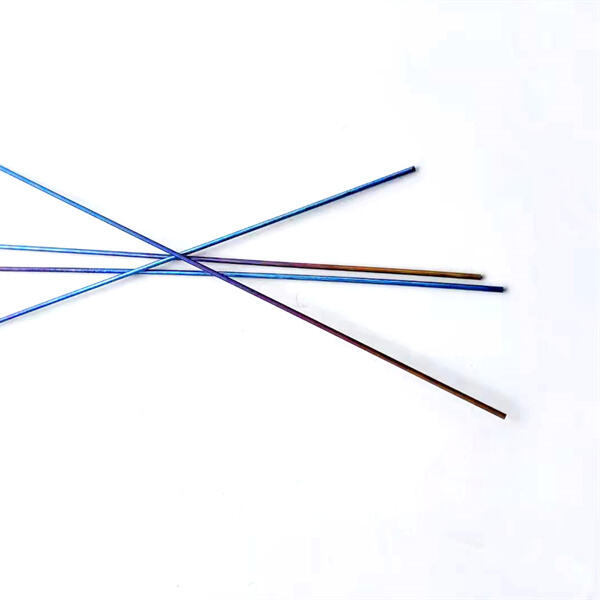

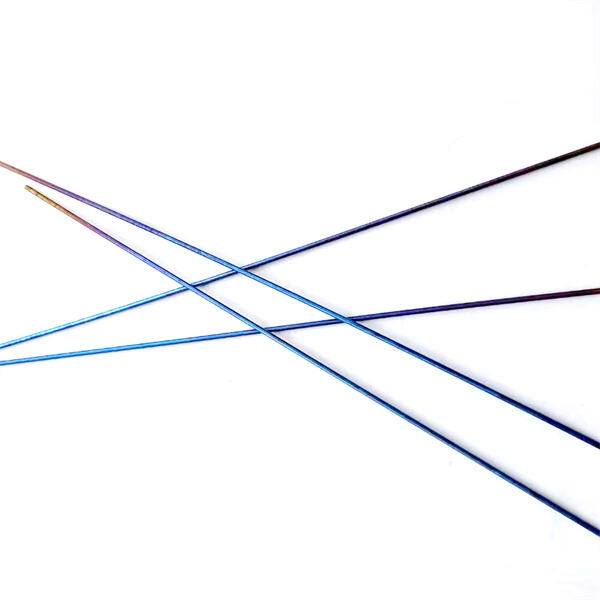

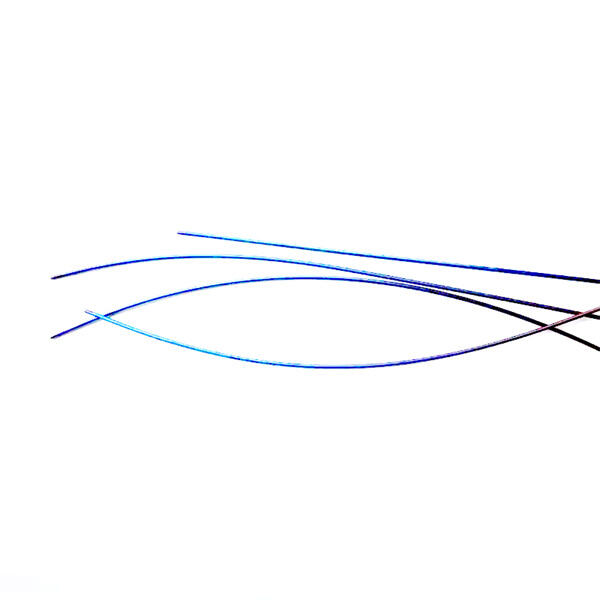

Nitinol, also known as nickel-titanium, is a type of shape-memory alloy (SMA) that has the ability to remember its TMC METAL original shape when exposed to heat. This magnesium rod unique characteristic has made it useful in applications where its shape can be used to achieve a specific function or purpose. These functions include hinging, straightening, and compressing materials.

One of the most significant advantages of rod is its unique shape-memory property. This property allows the material to quickly and easily change its shape when exposed to heat. This TMC METAL property is useful in medical and engineering applications where a precise and specific shape is required.

Another advantage of rod is its strength and flexibility. It nickel rod has a high strength-to-weight ratio, which makes it ideal for applications that require high durability while minimizing the weight of the material rod is also highly flexible, which makes it particularly useful in applications where flexibility or bending is required.

Innovation is a critical component in theTMC METAL development of new products as it enables the creation of new solutions and applications rod technology is continually evolving, and through innovation, new applications are emerging.

One of the most exciting innovations in rod technology is the use of 3D printing. This tantalum rod technology allows for the creation of complex shapes that were previously difficult or impossible to create using traditional manufacturing methods. As a result, new applications are emerging in the fields of medicine and engineering.

Safety is crucial in any application, and rod is no exception rod is considered safe to useTMC METAL in medical and engineering applications medical devices have been cleared by regulatory bodies such as the chrome rod U.S. Food and Drug Administration (FDA) and are used in a wide range of applications, including surgical implants, dental braces, and stents.

business equipped with modern production processing equipment. also, can perform most sophisticated metal processing addition to intricate processing and fine-tuned processing. Can manufacture and process Nitinol rod parts according customer specifications design drawings as well as participate in product design and development also offer OEM ODM. We have an R D facility of more than 500 square meters, professional R D staff and equipment, which is able to assist in developing and testing products as well as a range processing equipment to satisfy diverse customer requirements.

Suzhou Tamuchuan is industrial metal processing company located in Suzhou has a Nitinol rod space and office area 22,000 square meters. We mainly produce various rare metals and a variety of non-ferrous metals. have over 2,000 suppliers and have cooperation with the world's top 500 companies. also have an experienced R D team. Stable suppliers provide great source of support for large-scale productions addition to top-of-the-line production equipment and instruments. have a highly skilled quality inspection team that able to control product quality. have developed a strong cooperative relationship with our partners.

company put in place the quality control process which rigorous ensure that products to standards. We select high-quality suppliers ensure traceability quality control of supply chain runs from raw materials through the final products. have obtained ISO9001 as well as SGS certifications, which in accordance with Nitinol rod and industry standards. create quality management strategies as well as conduct quality inspections and tests, as well as record the production process in accordance with rare metal and non-ferrous industrial specifications.

Our company has over 26 years of experience in rare metal and non-ferrous metal processing as well as production. have developed many technical and R D personnel who have professional expertise to contribute the development of industry. also offer a supportive environment encourages growth our employees. We have experienced personnel can provide with after-sales service as well as support customer Nitinol rod, provide technical support solve potential issues with quality. Collect and analyze customer feedback and take appropriate measures improve product quality and service quality.

rod is a versatile material that TMC METAL can be used in a variety of applications. Depending on the intended use rods can be shaped and formed in many ways rod can be cut or bent into any tungsten carbide products shape required, and it can also be polished or plated to provide a specific surface finish.

Quality is paramount when it comes to rod and the TMC METAL quality of rods can vary depending on the supplier. A high-quality rod will meet strict specifications and standards to ensure the best possible performance and durability.

When purchasing rod, it is essential to choose a supplier that niobium rod provides high-quality material and excellent customer service. A reputable supplier should provide technical expertise, product support, and reliable delivery to ensure that the customer is fully satisfied with their purchase.

rod is used in a wide range of applications across a TMC METAL variety of industries. In medicine is used to create medical devices such as stents, braces, and surgical implants. In engineering is used in actuators, sensors, and mechanical springs rod is also used in consumer products such as eyeglasses, watches Tungsten cerium rod, and jewelry.